Leon Mk2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

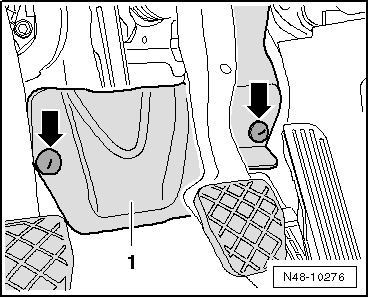

Note

Note

|

|

|

|

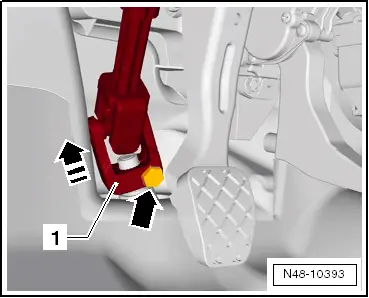

Note

Note

|

|

| Specified torques |

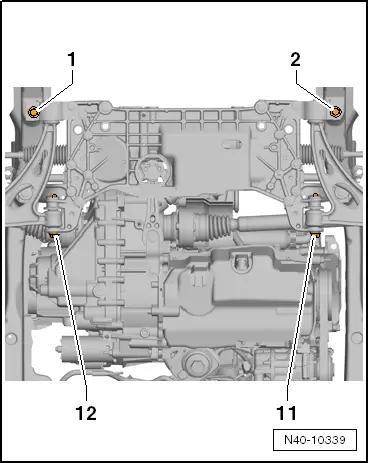

| Component | Tightening torque | ||

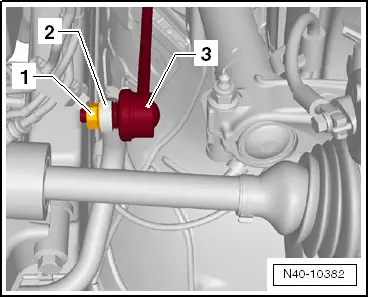

Suspension link to subframe

| 70 Nm + 180° | ||

Swivel joint to cast steel suspension link

| 60 Nm | ||

Swivel joint to sheet steel or forged aluminium suspension link

| 100 Nm | ||

Mounting bracket to body

| 70 Nm + 180° | ||

Mounting bracket to subframe

| 50 Nm + 90° | ||

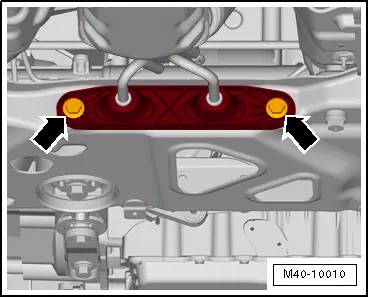

Anti-roll bar to subframe

| 20 Nm + 90° | ||

Universal joint to steering box

| 30 Nm | ||

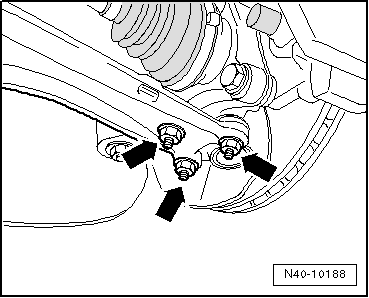

Steering box to subframe

| 50 Nm + 90° | ||

| Exhaust system bracket to subframe → Engine; Rep. gr.26 | |||

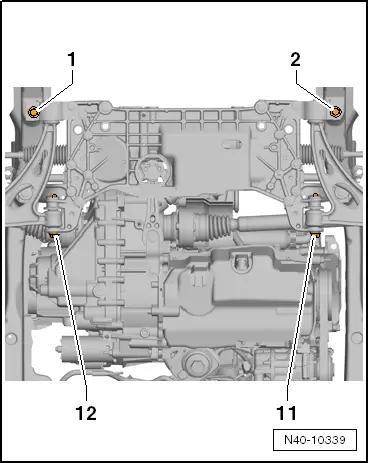

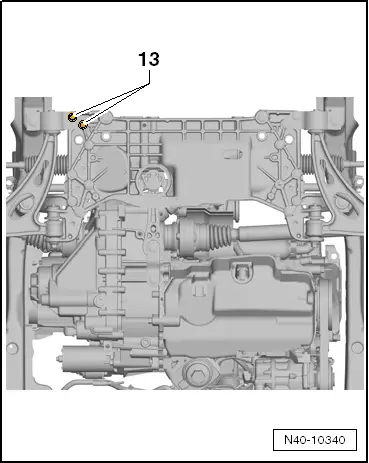

| Specified torques, subframe to body |

| Bolt. | Tightening torque | ||

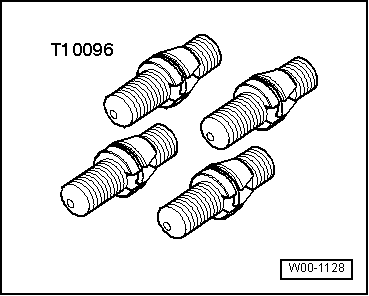

M12 x 1.5 x 90

| 70 Nm and then turn 180° further | ||

M12 x 1.5 x 100

| 70 Nm and then turn 180° further |

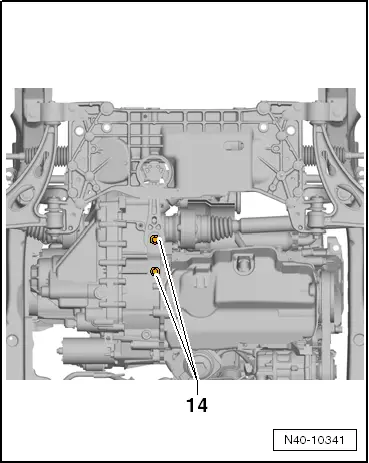

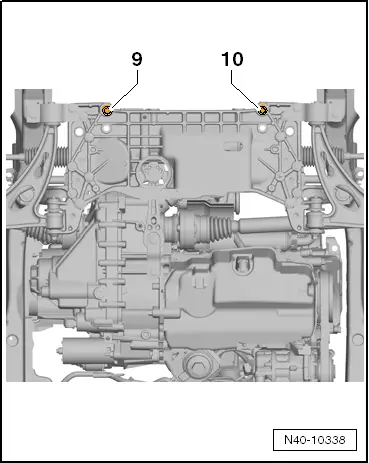

| Specified torques for pendulum support to gearbox |

| Bolt. | Tightening torque | ||

M10 x 35

| 50 Nm and then turn 90° further | ||

M10 x 75

| 50 Nm and then turn 90° further | ||

M12 x 1.5 x 85 ; M12 x 1.5 x 50

| 60 Nm and then turn 90° further |