| –

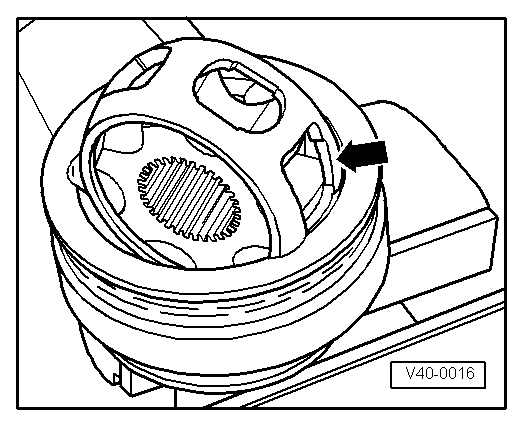

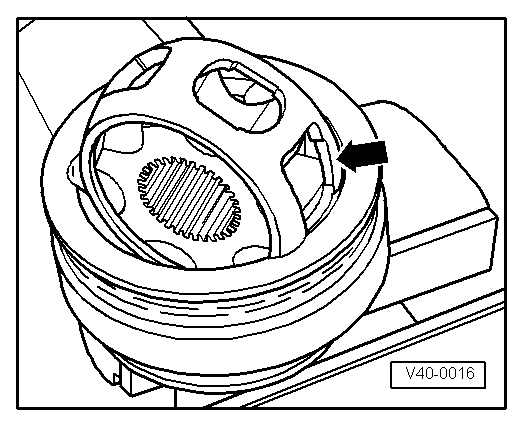

| Swing segment of hub into rectangular cage window. |

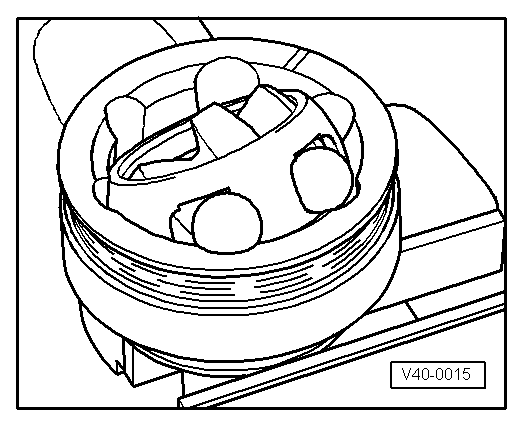

| The 6 balls of each joint belong to one tolerance group. Check stub axle, hub, cage and balls for small indentations (pitting) and signs of seizure. Excessive backlash in joint will be noticed as a knock during load changes. In such cases the joint must be renewed. Polished areas and tracks from balls are not a reason for changing the joint. |

| –

| Press half of the total amount of grease (40 g) into the joint body. |

| –

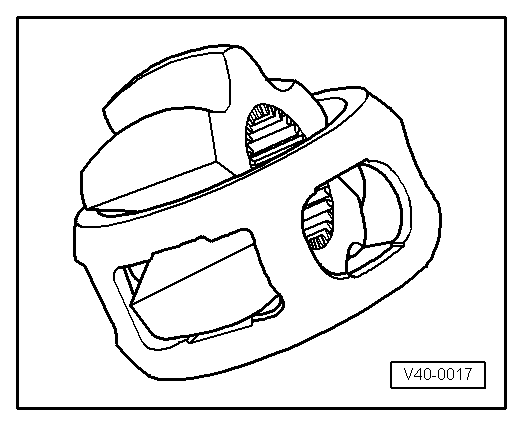

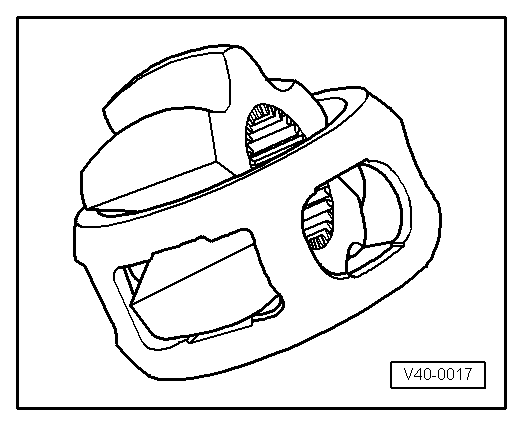

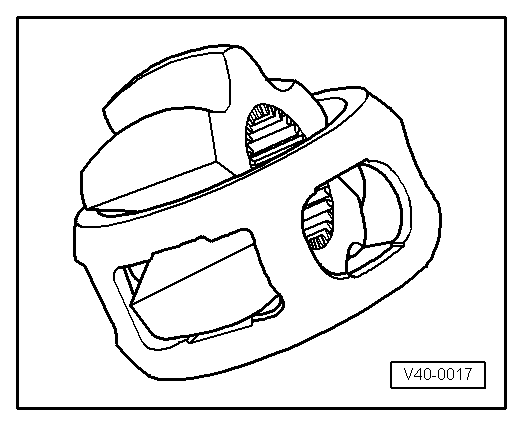

| Install cage with hub in the joint housing. |

| –

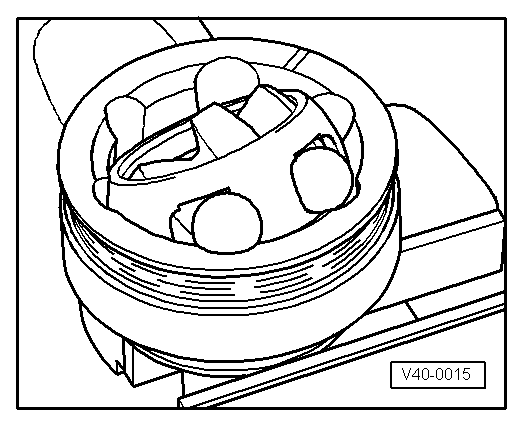

| Press in the balls one after the other from opposite sides whereby the original position of the hub to cage and joint housing must be restored. |

| –

| Fit new circlip in the hub. |

| –

| Distribute the remaining grease in the bellows. |

|

|

|