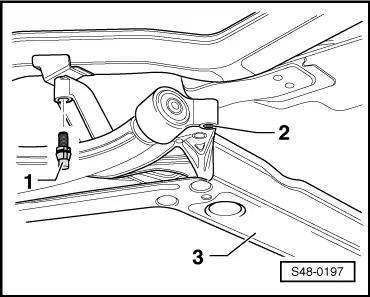

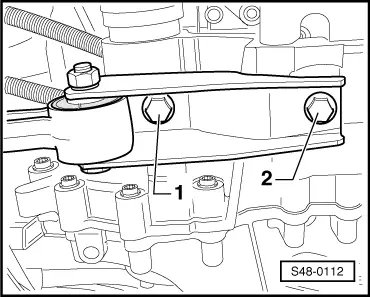

| Power-steering gear to assembly carrier | 50 Nm + 90° |

| Assembly carrier to body | 70 Nm + 90° |

| Support to body | 20 Nm + 90° |

| Pendulum support to gearbox | 30 Nm + 90° |

| Track rod end/track rod to steering arm | 20 Nm + 90° |

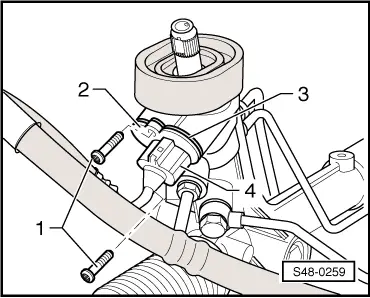

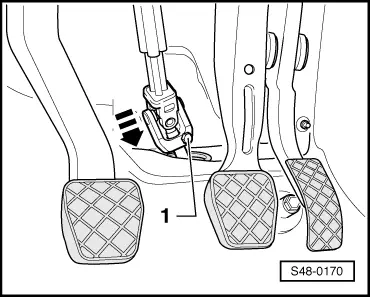

| power-assisted steering sensor -G250 - to power-assisted steering gear (TRW) | 6 Nm |

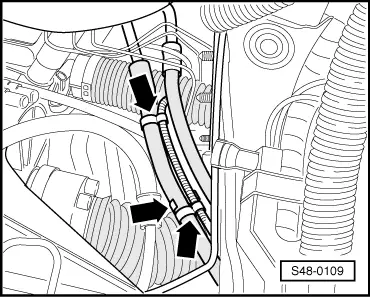

| Hollow screw for pressure line to power steering gear (M14x1.5) - TRW | 35 Nm |

| Pipe screw for return line to power steering gear (M16x1.5) | 30 Nm |

| Coupling rod to anti-roll bar | 40 Nm |

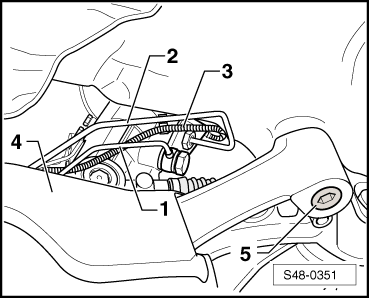

| Universal joint to power-steering gear | 20 Nm + 90° |

| Wheel bolts | 120 Nm |

Note

Note

Note

Note

Note

Note

Caution

Caution