| Checking charge pressure control |

| Special tools and workshop equipment required |

| t

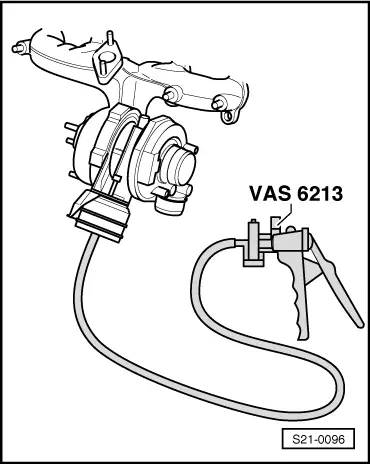

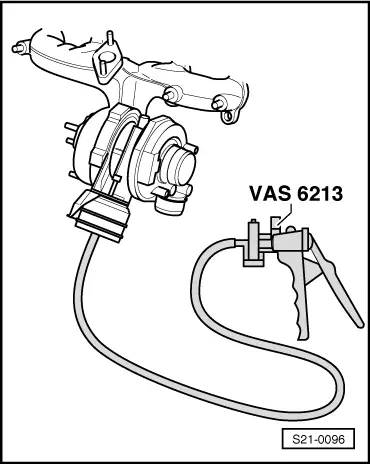

| Hand vacuum pump, e.g. -V.A.S 6213- |

| t

| Hand multimeter, e.g. -V.A.G 1715- |

| t

| Vehicle system tester -V.A.G 1552- |

| t

| Diagnostic cable -V.A.G 1551/3, 3A, 3B, 3C- |

| t

| Measuring tool set, e.g. -V.A.G 1594 C- |

| t

| Adapter cable -V.A.G 1598/31- |

| l

| No leaks on the intake and exhaust side |

| l

| No fault on the engine/fuel injection system |

| l

| Engine oil temperature at least 80 °C |

| If test and measuring devices are required during test drives observe the following: |

Note | t

| Always secure the test and measuring devices on the rear seat and have a second person operate them there. |

| t

| If the test and measuring equipment is operated from the front passenger seat, this can result in injuries to the persons sitting on that seat in the event of an accident which involves the front passenger airbag being deployed. |

| –

| The charge pressure is measured with vehicle system tester -V.A.G 1552- when the engine is idling and during a road test. |

| –

| Select function 04“Initiate basic setting” and the display group 011. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note