| –

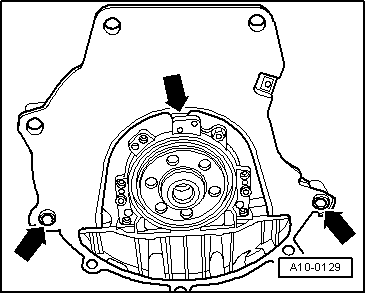

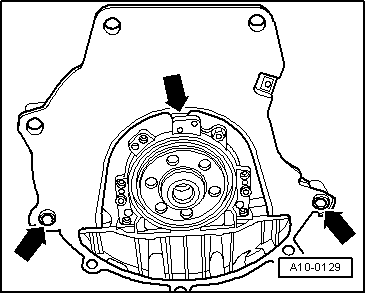

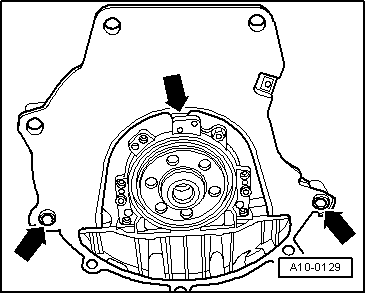

| Check whether the intermediate plate has been inserted on the sealing flange and rests on the dowel sleeves -arrows-. |

| –

| If necessary check the centering of the clutch driver disc. |

| –

| Inspect clutch release bearing for wear, replace if necessary. |

| –

| Grease the drive shaft serration with grease -G 000 100-. |

| –

| When installing engine/gearbox unit, ensure adequate clearance to neighbouring components. |

| –

| Align the engine/gearbox unit free of stress and attach firmly. |

|

| When tightening the bolts for engine and gearbox mounts, engine and gearbox support brackets must be resting fully against mount. |

| –

| Install the front exhaust pipe with catalytic converter and the exhaust system so that they are not under tension. → Chapter. |

| For vehicles with air conditioning |

| –

| Disconnect the refrigerant lines. |

| –

| Replacing dessicator insert. |

| –

| Filling the refrigerant circuit. |

Note | Only re-use drained coolant if none of the following components has been replaced: Engine block, cylinder head, radiator, heat exchanger. |

| –

| Check oil level before starting the engine. |

Note | t

| Tightening torques apply only for lightly greased, oiled, phosphatized or blackened nuts and screws. |

| t

| Other lubricants such as engine and gearbox oil are allowed. Do not use Molykote. |

| t

| Do not use degreased parts. |

| t

| Unless otherwise indicated the following tightening torques apply: |

|

|

|

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note