| –

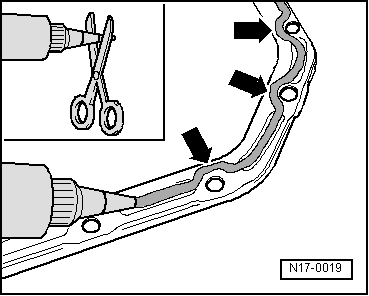

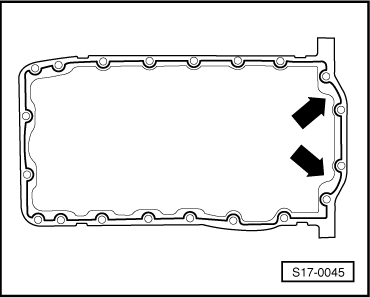

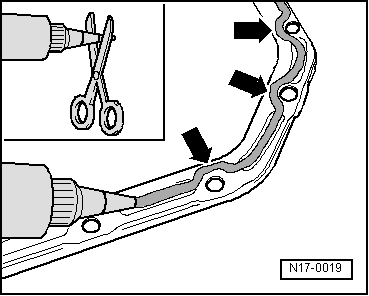

| Apply silicone sealant to the clean sealing surface of the oil pan, as shown in the illustration. |

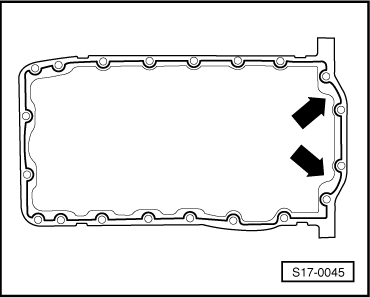

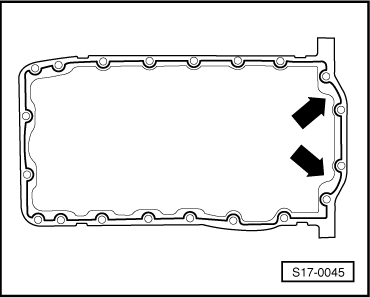

Note | Take particular care when applying sealant bead in the area of the sealing flange at the rear -arrows-. |

| –

| Fit on oil pan immediately and tighten the bolts as follows: |

| 1 - | Tighten all the bolts of oil pan/cylinder block slightly diagonally across. |

| 2 - | Tighten the three bolts of oil pan/cylinder block slightly. |

| 3 - | Tighten all the bolts of oil pan/cylinder block slightly diagonally across. |

| 4 - | Tighten the three bolts of oil pan/gearbox to 45 Nm. |

| 5 - | Tighten all the bolts of oil pan/cylinder block diagonally across to 15 Nm. |

Note | t

| When installing the oil pan with the engine removed, ensure that the oil pan is flush with the cylinder block at the flywheel side. |

| t

| After installing the oil pan, allow the sealant to dry for about 30 minutes. Only then may engine oil be filled in. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note