Fabia Mk1

|

| (Gearbox removed) |

Note

Note| t | Replace the clutch discs and pressure plates if the riveting is damaged or loose. |

| t | Make the clutch disc and pressure plate coincide in accordance with the spare part catalogue and engine identification characters. |

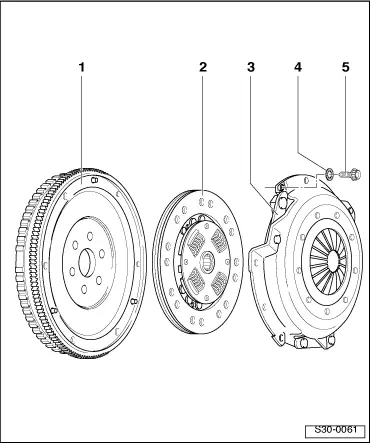

| 1 - | Flywheel |

| q | make sure the centering pins are tight |

| q | The locating face for the clutch lining must be free from grooves, oil and grease |

| q | removing and installing → The Engine; Rep. Gr.13 |

| 2 - | Clutch disc |

| q | Diameter → Chapter |

| q | Fitting position: the spring cage pointing towards the pressure plate |

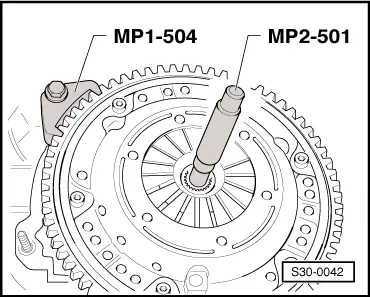

| q | center → Fig. |

| q | slightly grease the serration |

Note

Note| t | Clean serration of the drive shaft; this especially applies for used clutch discs. Remove corrosion and only apply a very thin layer of grease G 000 100 on the drive shaft serration. |

| t | Subsequently move the clutch disc up and down on the drive shaft until the hub on the disc is no longer absolutely smooth on the shaft. |

| t | Remove all excess grease. |

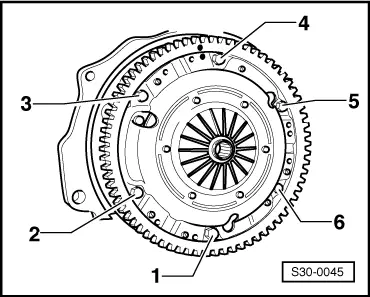

| 3 - | Pressure plate |

| q | removing and installing → Fig. |

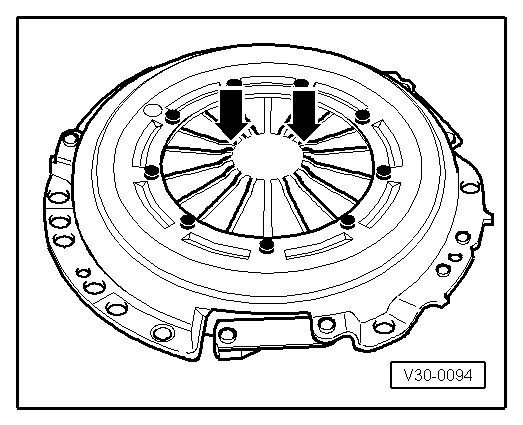

| q | Check the extremities of the membrane spring → Fig. |

Note

Note| The pressure plates are protected against corrosion and are greased. Only clean the thrust surface as otherwise the life of the clutch may be considerably reduced. |

| 4 - | 25 Nm |

| q | removing and installing → Fig. |

|

|

|

|