| –

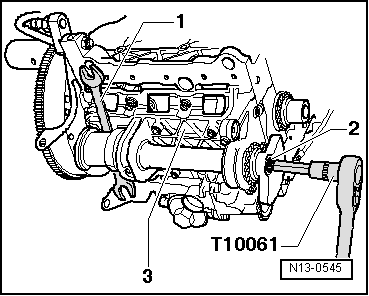

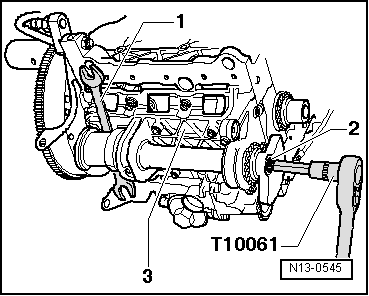

| Lock balancing shaft with open-end wrench -1-. |

Note | The open-end wrench must be positioned in the centre for the safety weight of the balancing shaft and at right angles to the balancing shaft. |

| –

| Loosen fixing bolt -2- for balancing weight. |

Note | Only loosen fixing bolt -2- for balancing weight, do not unscrew. |

| –

| Unscrew retaining frame -3- from cylinder block and remove retaining frame with balancing shaft. |

| –

| Lay aside retaining frame on a clean surface. |

| –

| Unscrew fixing bolt from the balancing weight. |

| –

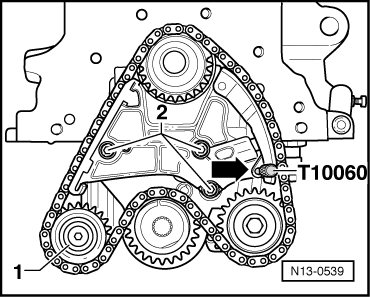

| Remove balancing weight and chain sprocket from the balancing shaft. |

| –

| Turn balancing shaft in such a way that it can be taken out of its bearing. |

| –

| Oil work surfaces of the bearing. |

| –

| Insert balancing shaft in the bearing. |

| –

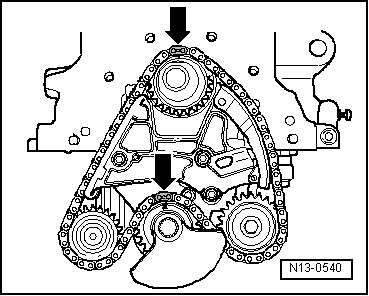

| Slide chain sprocket and balancing weight onto the balancing shaft. |

Note | Assembly of chain sprocket and balancing weight is only possible in one position. |

| –

| Tighten fixing bolt for balancing weight and chain sprocket by hand. |

| –

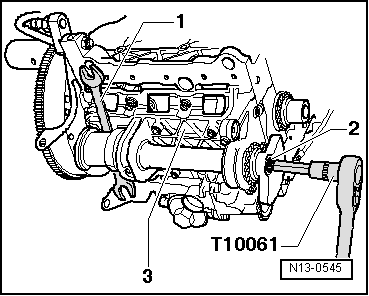

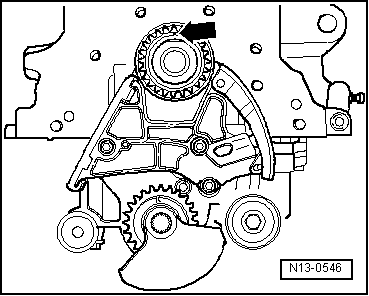

| Screw retaining frame onto cylinder block clearance free and by hand. |

Note | t

| When installing the retaining frame ensure, that the dowel sleeve is seated in the cylinder block and the O-ring in the retaining frame. |

| t

| Align retaining frame in such a way, that it is aligned on the belt pulley side with the cylinder block outer side. |

| –

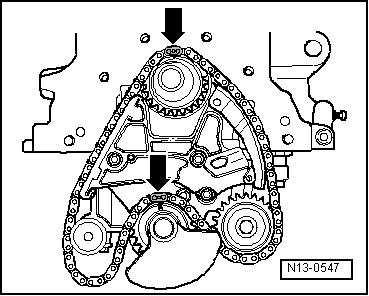

| Screw retaining frame with balancing shaft onto cylinder block. |

| Tightening torque: 20 Nm. |

| –

| Check if the retaining frame is aligned on the belt pulley side with the cylinder block outer side. |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note