| –

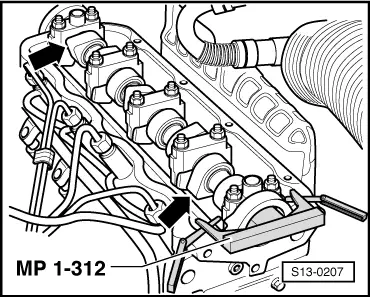

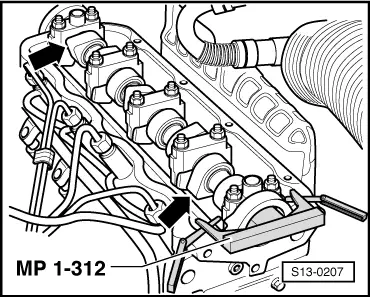

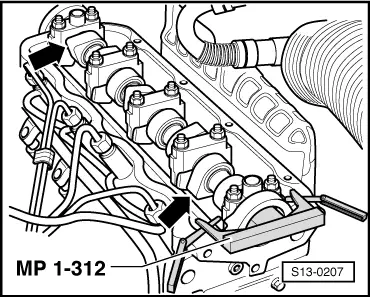

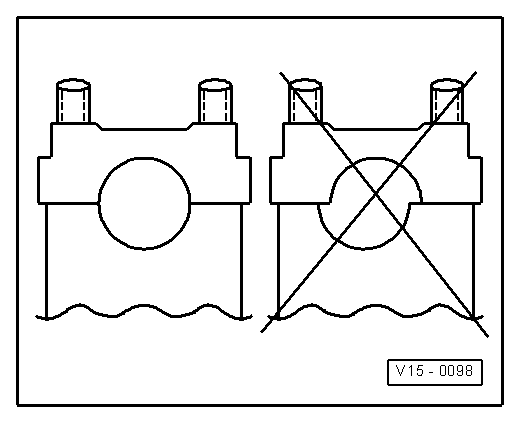

| Lock the camshaft with the camshaft straightedge -MP1-312-. |

Note | The valves for cylinder 1 must be closed and the valves for cylinder 4 must overlap. |

| –

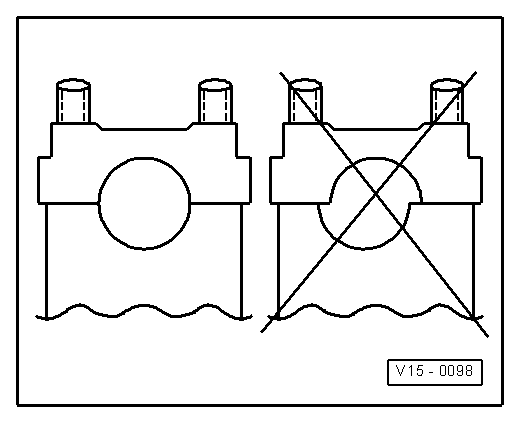

| Centre camshaft straightedge as follows: |

|

| Turn locked camshaft in such a way that one end of the camshaft straightedge strikes the cylinder head. Measure the resulting gap at the other end of the camshaft straightedge with a feeler gauge.

Insert feeler gauge with halved thickness between the camshaft straightedge and the cylinder head. Turn the camshaft until one end of the camshaft straightedge strikes the feeler gauge.

Insert the second feeler gauge of the same thickness between the opposite end of the straightedge and the cylinder head. |

| Further installation occurs in reverse order. |

Note | t

| After carrying out work on the valve gear, carefully crank engine at least 2 revolutions to ensure that no valve touches the piston when the engine is started. |

| t

| After installing new bucket tappets, the engine must not be started for about 30 minutes. The hydraulic clearance compensation elements must settle (otherwise valves would strike the pistons). |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note