| –

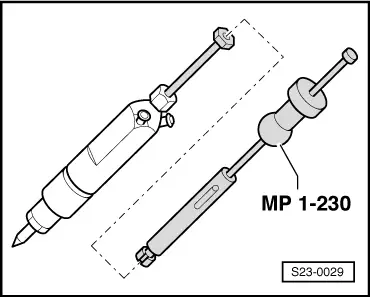

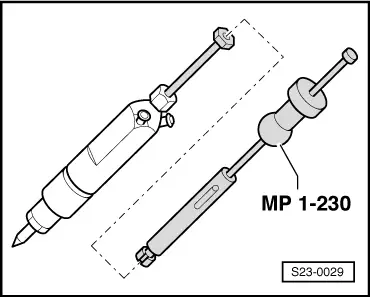

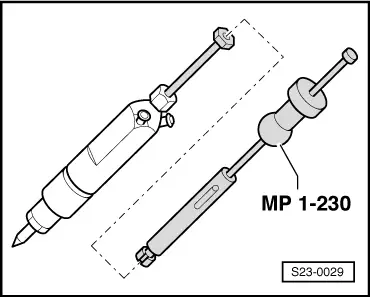

| Tighten the union nut of the auxiliary tool on the jammed nozzle and insert the extractor -MP1-230- on the welded nut. |

Note | Store the auxiliary tool with dust protection for future use. |

Note | Always replace the copper seals between the cylinder head and the injection nozzles. |

| –

| Replace the injection nozzles. |

| –

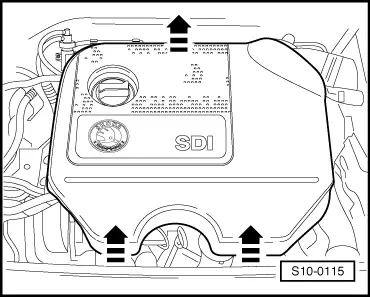

| Pay attention to the correct position of the brackets in the cylinder head. |

| –

| Insert clamp and tighten fixing screws. |

|

| Hollow screw for return-flow line (cylinder 3): 10 Nm |

|

| Specified value at idling speed: -2.80 mg/s up to +2.80 mg/s (milligram per stroke) |

| –

| Read off the measured values for the individual cylinders in the measured value block 13. |

| –

| If one or more measured values are outside the tolerance, interchange the injection nozzles (except for the nozzle of cylinder 3). |

| –

| If the fault migrates with the nozzle, replace the injection nozzle. |

| –

| If the fault remains on the cylinder, check the compression → Chapter. |

| –

| If the compression is O.K., replace the relevant connection fitting Pos. 11 with pressure valve and gasket ring on the injection pump → Chapter. |

Note | t

| The gasket ring must be removed from the pump with a soft object (plastic, wood) as otherwise the contact surfaces may be scratched. |

| t

| For mileages above 15 000 km replace the connection fitting with pressure valves per set only. |

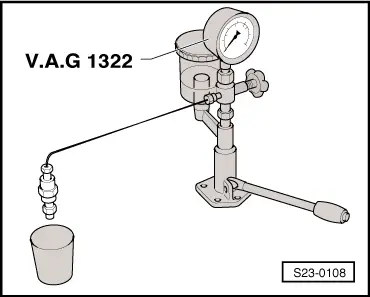

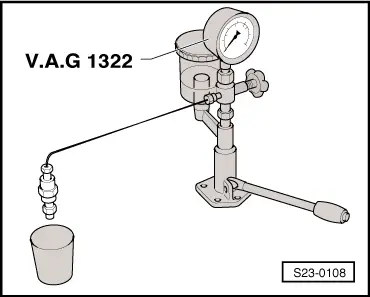

| This engine is fitted with 2 spring injection nozzles. This is why the injection of the fuel quantity occurs in 2 steps. If there is a problem with these injection nozzles they must be replaced, as neither a pressure adjustment nor a repair is possible. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note Note

Note