| Inspecting the injection rate, tightness and jet formation of the injectors |

| Special tools and workshop equipment required |

| t

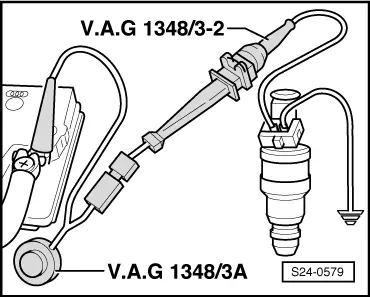

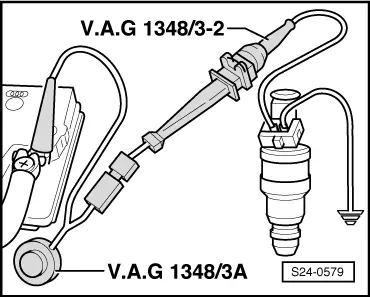

| Remote control, e.g. -V.A.G 1348/3A- |

| t

| Adapter, e.g. -V.A.G 1348/3-2- |

| t

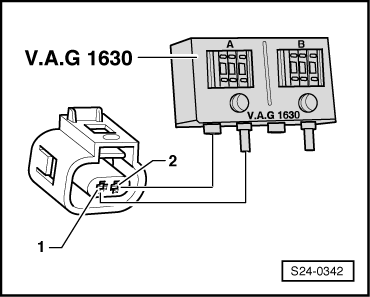

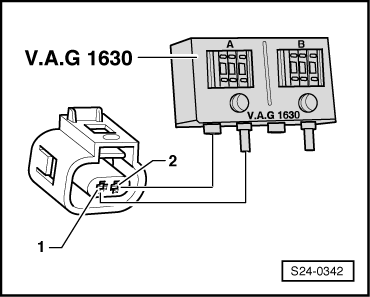

| Digital potentiometer, e.g. -V.A.G 1630- |

| t

| Measuring tool set, e.g. -V.A.G 1594 A, B, C- |

| t

| Hand multimeter, e.g. -V.A.G 1602- |

| l

| Fuel temperature 15...20°C, fuel must be according to the valid standards. |

| –

| If necessary remove engine cover with air filter → Chapter. |

| –

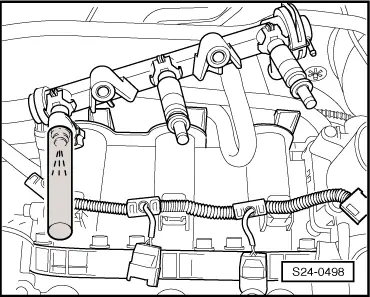

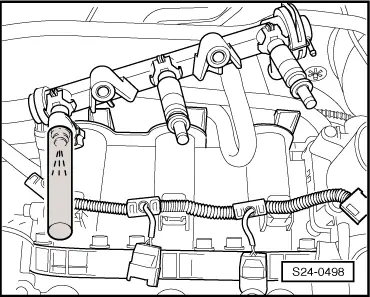

| Remove fuel strip together with installed injectors → Chapter. The fuel hoses remain connected. |

| Testing jet formation and tightness |

| –

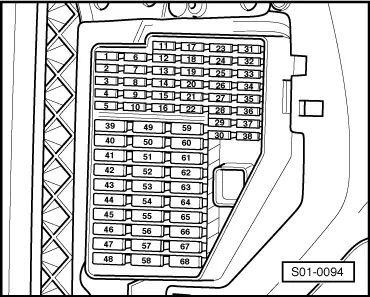

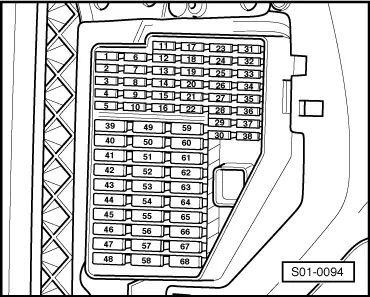

| Disconnect plug at coolant temperature sender -G62- → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note