| Removing and installing the hydraulic control unit and the bracket |

Note | Make absolutely sure that no brake fluid gets into the plug connector housing of the control unit. This may result in the corrosion of the contacts and to system failure. Carefully clean out the plug connector housing with compressed air if it gets dirty. |

| Special tools and workshop equipment required |

| t

| Vehicle system tester -V.A.G 1552- |

| t

| Diagnostic cable -V.A.G 1551/3, 3A, 3B oder 3C- |

| t

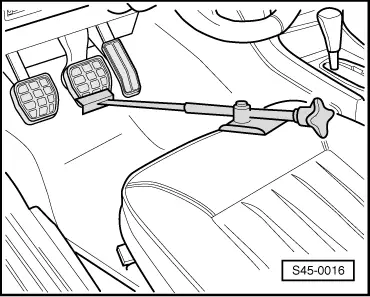

| Brake pedal load, e.g. -V.A.G 1238/B- |

| t

| Caps from the repair set SP no. -1 HO 698 311 A- |

| t

| Brake filling and bleeding device, e.g. -VAS 5234- |

| t

| Extraction bottle (commercially available) |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note