| –

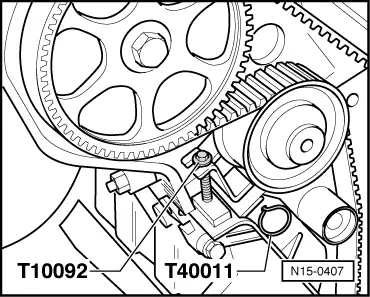

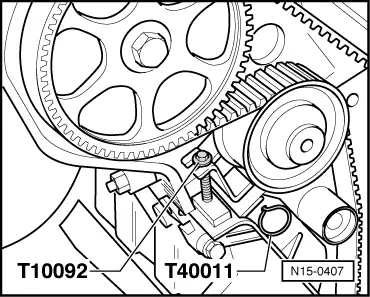

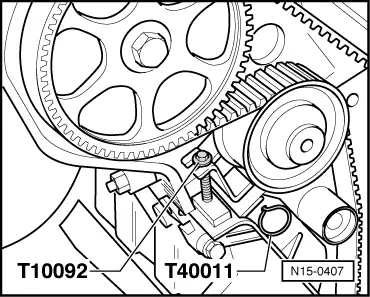

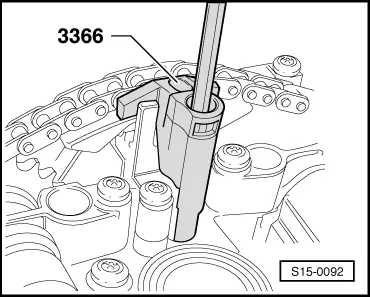

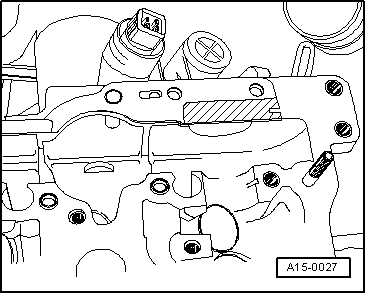

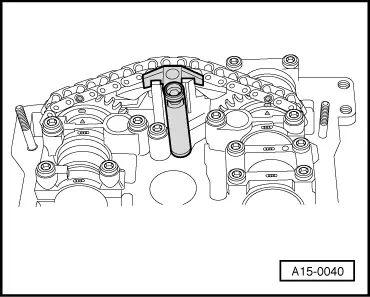

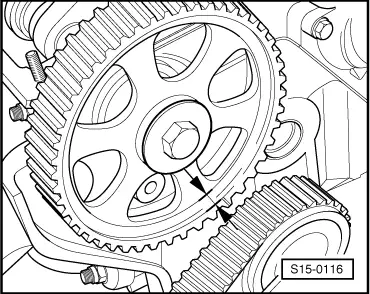

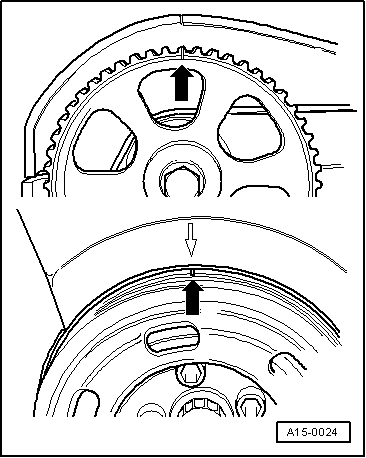

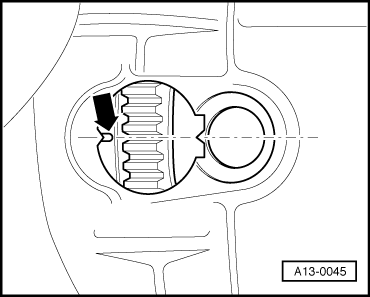

| Pull out rig pin -T40011 - and slacken pressure piston of tensioning device. Screw out the tensioning screw -T10092-. |

| –

| Install top toothed belt guard. |

| –

| Install the V-ribbed belt and clamping fixture → Chapter. |

Note | t

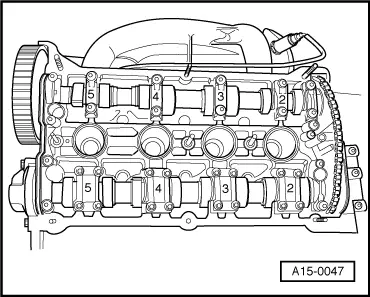

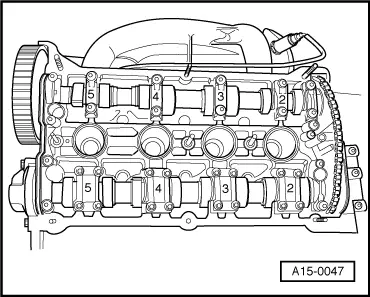

| After installing the camshafts, the engine must not be started for about 30 minutes. The hydraulic clearance compensation elements must settle (otherwise valves would strike the pistons). |

| t

| After carrying out work on the valve gear, carefully crank engine in the direction of running at least 2 revolutions to ensure that no valve touches the piston when the engine is started. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note