Octavia Mk1

Note

Note| t | The clutch must only be disassembled for cleaning and for carrying out a visual inspection. |

| t | On certain gearboxes, the clutches -K1- and -K3- can be pressed together. |

| t | press off -K1- from -K3- → Chapter. |

| t | press -K1- onto -K3- → Chapter. |

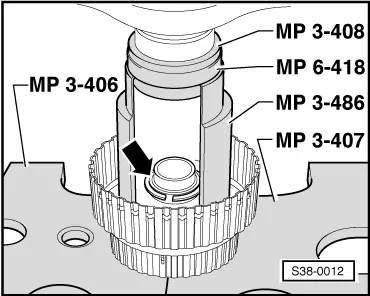

| 1 - | Top mount |

| q | 4-part, unclip from inner plate support |

| q | inserting → Fig. |

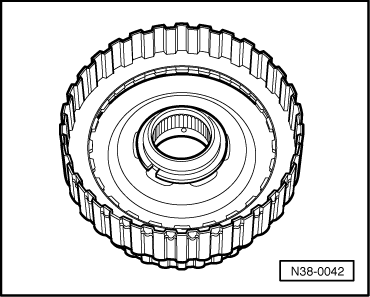

| 2 - | Inner plate support |

| q | inserting → Fig. |

| q | assembling → Fig. |

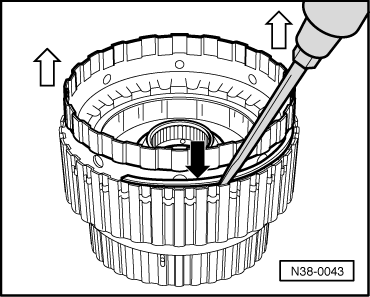

| 3 - | Circlip |

| q | Differing thickness |

| q | mark after removing and install again in same position |

| q | do not interchange with circlips of other clutches |

| 4 - | Pressure plate |

| q | smooth side to the inner plate |

| q | insert together with the inner plate support → Fig. |

| 5 - | Inner plate |

| q | Piece number → Chapter |

| q | installing → Fig. |

| q | place new inner plate into ATF for 15 minutes before installing |

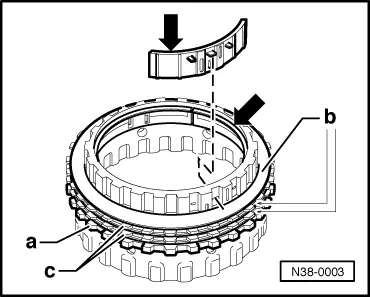

| 6 - | Outer plate |

| q | Piece number → Chapter |

| q | installing → Fig. |

| q | always 1.5 mm thick |

| 7 - | Outer plate |

| q | always 2.0 mm thick |

| q | installing → Fig. |

| 8 - | Wave spring washer |

| 9 - | Circlip |

| q | removing and installing → Fig. |

| q | mark after removing and install again in same position |

| q | do not interchange with circlips of other clutches |

| 10 - | Piston cap |

| q | The sealing lips are vulcanized to the cover |

| q | moisten sealing lips with ATF before inserting |

| q | turn piston cap slightly when installing |

| 11 - | Spring spacer ring |

| q | with spring support panel and pressure springs |

| 12 - | Piston |

| q | for removal, lift off from the clutch bell at several points using a screwdriver |

| q | The sealing lips are vulcanized to the pistons |

| q | moisten sealing lips with ATF before inserting |

| q | turn piston slightly when installing |

| 13 - | Clutch bell |

| q | before installing the inner plate support of the wave spring washer Pos. 8, place the inner and outer plates in the clutch bell → Fig. |

|

|

Note

Note

|

|

|

|

|

|