Octavia Mk1

Note

Note| t | If the tapered-roller bearings are used again, the adjusting ring -Pos. 5- must be marked → Fig. |

| t | The input shaft must not be removed for removing and installing the differential gear. |

| 1 - | Drive for speedometer, 10 Nm |

| q | with marking for axle oil level |

| q | removing and installing → Chapter |

| 2 - | Gearbox housing |

| 3 - | Output shaft for joint flange |

| q | remove before removing the differential gear |

| q | remove circlip Pos. 31 for removing |

| q | install only after adjusting the differential gear |

| q | Install thread to joint flange |

| 4 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

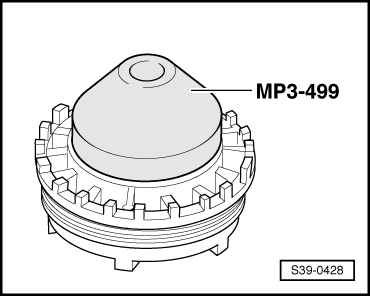

| 5 - | Adjusting ring |

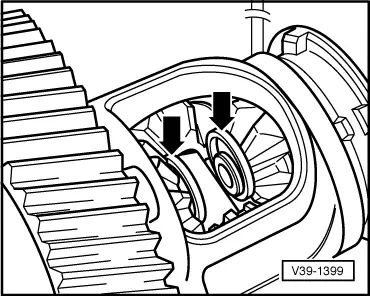

| q | removing → Fig. |

| q | mark fitting position for re-using used bearing and position again on the marking when installing → Fig. |

| q | observe setting instruction when installing new bearings → Chapter |

| 6 - | Gasket ring for joint flange |

| q | can be replaced on an installed gearbox → Chapter |

| q | remove with ejection lever -MP3-418 (VW 681)- |

| q | before installing, fill half the space between the sealing lips with sealing grease -G 052 128 A1- |

| q | inserting → Fig. |

| 7 - | Conical ring |

| q | Collar points to thrust washer |

| 8 - | Thrust washer |

| q | position over the pressure spring |

| 9 - | Pressure spring |

| 10 - | Joint flange |

| q | remove before removing the inner circlip at the differential bevel gear |

| q | removing and installing on installed gearbox in order to replace the gasket ring for joint flange → Chapter |

| q | insert with conical ring, stop disc and pressure spring |

| 11 - | Disc spring |

| q | curved side points outwards |

| 12 - | Circlip |

| 13 - | Screw cap |

| 14 - | Retaining clip |

| 15 - | 12 Nm |

| q | insert using locking agent -AMV 185 101 A1- |

| 16 - | Screw cap |

| 17 - | Circlip |

| 18 - | Disc spring |

| q | curved side points outwards |

| 19 - | Joint flange |

| q | remove before removing the inner circlip at the differential bevel gear |

| q | removing and installing on installed gearbox in order to replace the gasket ring for joint flange → Chapter |

| q | insert with conical ring, stop disc and pressure spring |

| 20 - | Pressure spring |

| 21 - | Thrust washer |

| q | position over the pressure spring |

| 22 - | Conical ring |

| q | Collar points to thrust washer |

| 23 - | Gasket ring for joint flange |

| q | can be replaced on an installed gearbox → Chapter |

| q | remove with ejection lever -MP3-418 (VW 681)- |

| q | before installing, fill half the space between the sealing lips with sealing grease -G 052 128 A1- |

| q | inserting → Fig. |

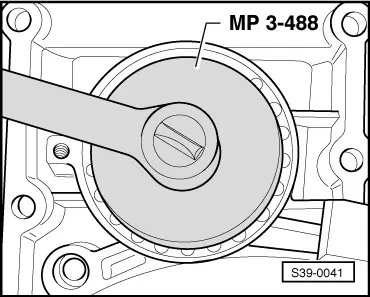

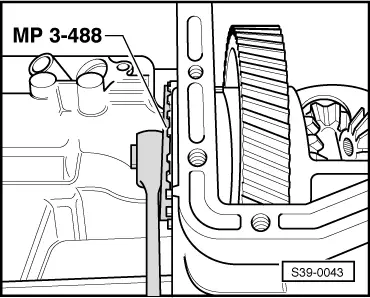

| 24 - | Bearing body, 150 Nm |

| q | remove with wrench for lifting eye nut -MP3-488 (3155)- |

| q | observe setting instruction when installing new bearings → Chapter |

| q | installing → Fig. |

| 25 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

| 26 - | Output shaft for joint flange |

| q | remove before removing the differential gear |

| q | remove circlip Pos. 30 for removing |

| q | install only after adjusting the differential gear |

| q | Install thread to joint flange |

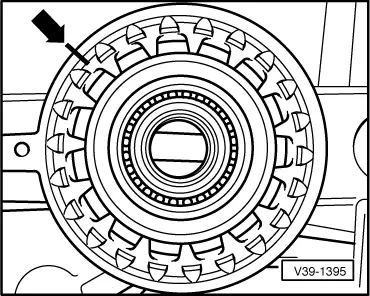

| 27 - | Differential gear |

| q | remove bearing body, adjusting ring and output shafts before removing the differential gear |

| q | disassembling and assembling → Chapter |

| 28 - | 12 Nm |

| q | insert using locking agent -AMV 185 101 A1- |

| 29 - | Retaining clip |

| q | secure the bearing body Pos. 24 and the adjusting ring Pos. 5 after adjusting the tapered-roller bearing |

| 30 - | Circlip |

| q | remove only after removing the joint flange as the pressure spring Pos. 20 is pretensioned |

| q | removing and installing → Fig. |

| 31 - | Circlip |

| q | remove only after removing the joint flange as the pressure spring Pos. 9 is pretensioned |

| q | removing and installing → Fig. |

| 32 - | Gasket |

| q | always replace → Electronic Catalogue of Original Parts |

| 33 - | Cover |

| q | for differential gear |

| q | “older” version without inspection plug |

| 34 - | 28 Nm |

| q | insert using locking agent -AMV 185 101- |

| 35 - | Cover |

| q | for differential gear |

| q | “new” version with inspection plug |

| 36 - | Inspection plug, 25 Nm |

| q | with gasket |

| q | Check the axle oil with the gearbox installed → Chapter |

|

|

|

|

|

|

|

|

|

|