Octavia Mk1

Note

Note| t | Before pressing on the inner ring/tapered-roller bearing heat up to 100°C. |

| t | Adjusting ring for tapered roller bearing - before pressing in outer ring/tapered roller bearing - heat up to 100°C. |

| 1 - | Differential gear housing |

| q | with riveted pinion for final drive |

| q | The pinion for the final drive is riveted on the differential gear housing and subsequently machined |

| q | if the differential gear housing or the pinion for the final drive is damaged, the differential gear housing is replaced together with the riveted pinion for the final drive |

| q | Number of teeth of the final drive pinion → Chapter |

| q | there are various differential gear housings depending on the diameters of the tapered-roller bearings. |

| 2 - | Output shaft for joint flange |

| q | removing and installing → Chapter |

| 3 - | Inner ring/tapered-roller bearing |

| q | there are different sizes of tapered-roller bearings. The fitting position can vary |

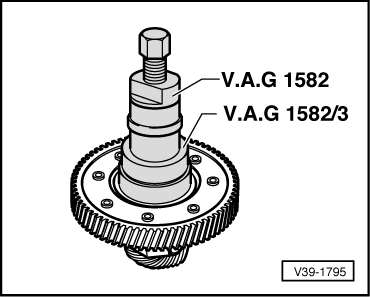

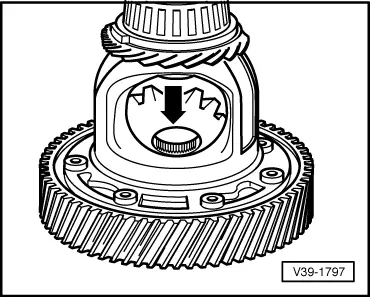

| q | remove the two “identical” bearings on both sides → Fig. |

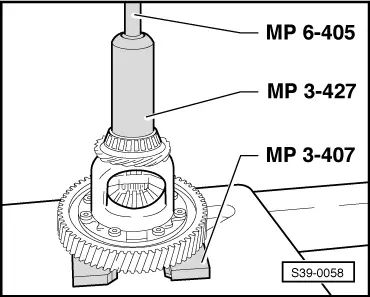

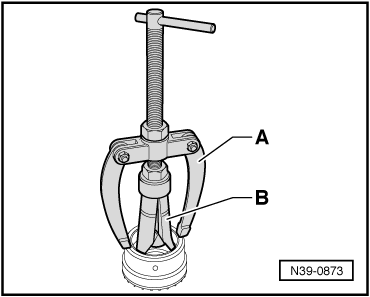

| q | remove the “larger” bearing → Fig. |

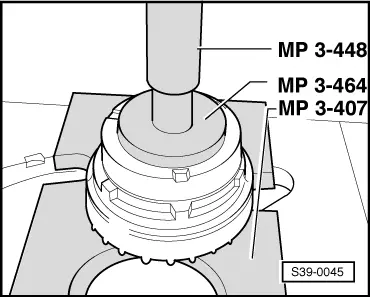

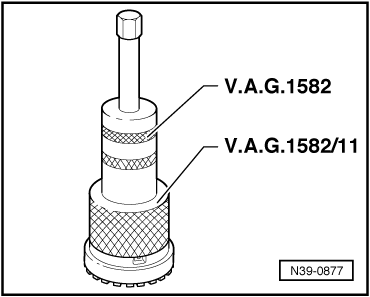

| q | press on → Fig. (for bearings of equal size on both sides) |

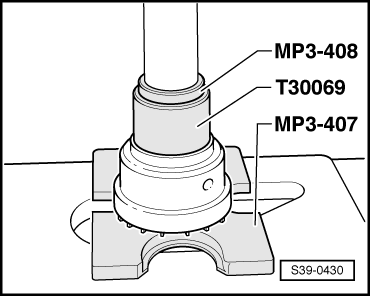

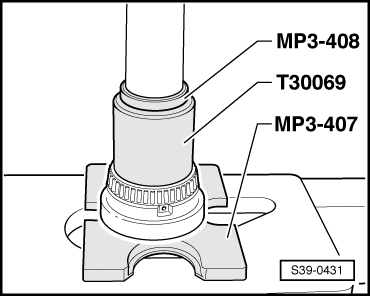

| q | press into the housing for the “larger” bearing on one side → Fig. |

| 4 - | Outer ring/tapered-roller bearing |

| q | only remove and install if the bearing body is heated Pos. 5 |

| q | drive out with drift |

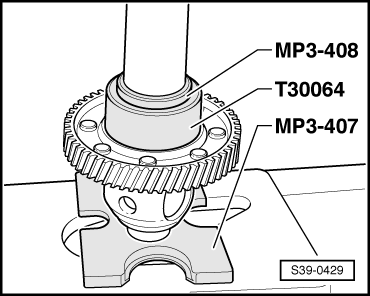

| q | installing → Fig. |

| 5 - | Bearing body for tapered-roller bearing |

| q | there are various bearing bodies |

| q | removing and installing → Chapter |

| q | Remove inner rings for tapered-roller bearing → Fig. |

| q | Press in outer ring for tapered-roller bearing → Fig. |

| q | Press on inner ring for tapered-roller bearing → Fig. |

| 6 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

| 7 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

| 8 - | Adjusting ring for tapered roller bearing |

| q | removing and installing → Chapter |

| 9 - | Output shaft for joint flange |

| q | removing and installing → Chapter |

| 10 - | Outer ring/tapered-roller bearing |

| q | only remove and install if the adjusting ring is heated Pos. 8 |

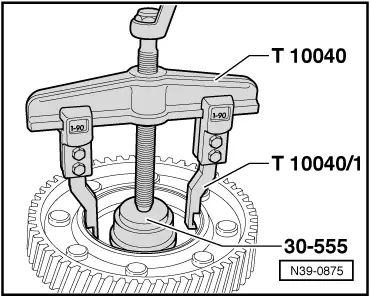

| q | pull out → Fig., if necessary drive out with drift |

| q | installing → Fig. |

| 11 - | Inner ring/tapered-roller bearing |

| q | there are different sizes of bearings |

| q | before detaching, remove Pos. 12 and 13 |

| q | detach → Fig. (for bearings of equal size on both sides) |

| q | pressing on → Fig. |

| 12 - | Tappet bushing |

| q | remove together with drive wheel for speedometer Pos. 13 |

| q | remove with a drift |

| 13 - | Drive wheel for speedometer |

| q | drive out with drift |

| q | position with tappet bushing Pos. 12 |

| 14 - | Stop disc compound |

| q | position in the differential gear housing before inserting the differential bevel gears |

| 15 - | Differential bevel gear, small |

| q | inserting → Fig. |

| 16 - | Differential bevel gear, large |

| q | inserting → Fig. |

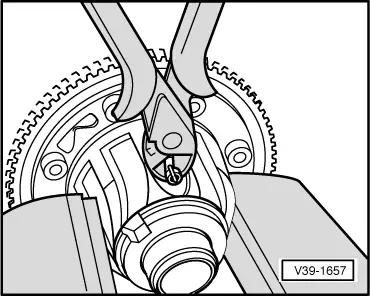

| 17 - | Circlip |

| q | remove circlip only after removing the joint flange, as the pressure spring is pretensioned |

| q | removing → Fig. |

| 18 - | Differential bevel gear shaft |

| q | for removing, remove tensioning sleeve Pos. 19 |

| q | drive out with drift |

| q | when driving in, do not damage stop disc compound |

| 19 - | Tensioning sleeve |

| q | replace |

| q | to secure the differential bevel gear shaft |

| q | removing and installing → Fig. |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|