Octavia Mk1

| Summary of components - engines with identification characters AEH, AKL |

| 1 - | 100 Nm |

| q | to release and tighten use counterholder -MP1-216 (3036)- |

| 2 - | Camshaft sprocket |

| q | with sensor rotor for the Hall sensor -G40- |

| q | for removal and installation, remove toothed belt → Chapter |

| q | Installation position fixed by woodruff key -pos. 4- |

| 3 - | Sealing ring |

| q | replace → Chapter |

| q | pay attention to different version |

| 4 - | Woodruff key |

| q | check tightness |

| 5 - | 20 Nm |

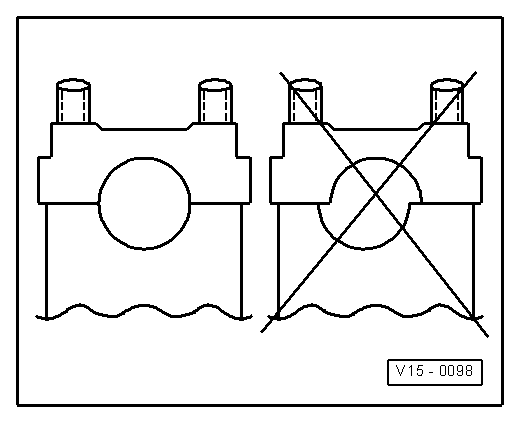

| 6 - | Bearing caps |

| q | Fitting position → Fig. |

| q | Mounting sequence → Chapter |

| q | Lightly coat head contact surface 1 with sealant -AMV 174 004 01- |

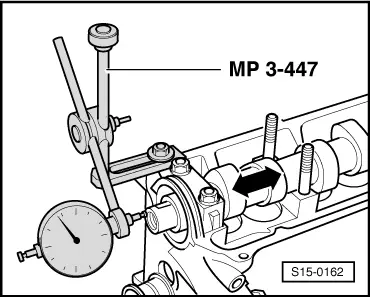

| 7 - | Camshaft |

| q | Inspecting axial play → Fig. |

| q | removing and installing → Chapter |

| q | Slack: max. 0,05 mm |

| 8 - | Bucket tappets |

| q | do not interchange |

| q | with hydraulic valve clearance compensation |

| q | check → Chapter |

| q | lay aside with contact surface facing down |

| q | before installing check axial play of the camshaft → Fig. |

| q | oil contact surface |

| 9 - | Valve collets |

| 10 - | Valve spring retainer |

| 11 - | Valve spring |

| q | removing and installing: |

| t | with cylinder head removed, with valve lever -MP1-211 (VW 541/1a,/5)- and assembly device for valves -MP1-213 (2036)- with valve supporting plate -MP1-218- |

| t | (with cylinder head installed) → Chapter |

| 12 - | Valve stem seal |

| q | replace → Chapter |

| 13 - | Valve guide |

| q | check → Chapter |

| q | replace → Chapter |

| q | Repair of the guide with a collar |

| 14 - | Cylinder head |

| q | pay attention to the notes → Anchor |

| q | reworking valve seats → Chapter |

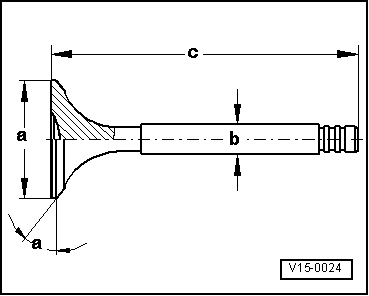

| 15 - | Valve |

| q | do not rework, only grinding in is permissible |

| q | Valve dimensions → Fig. |

|

|

Note

Note

|

|

| Dimension | Inlet valve | Exhaust valve | |

| Ø a | mm | 39,5 ± 0,15 | 32,9 ± 0,15 |

| Ø b | mm | 6,92 ± 0,02 | 6,92 ± 0,02 |

| c | mm | 91,85 | 91,15 |

| α | ∠° | 45 | 45 |