Octavia Mk2

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

| Tightening torques: |

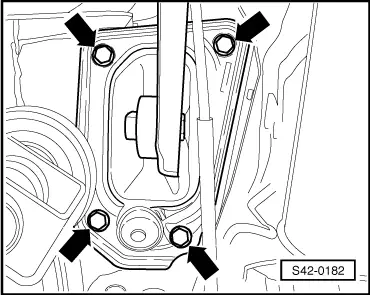

Mounting bracket on the body

| 50 Nm +45° | ||

Assembly carrier to body

| 90 Nm + 90° | ||

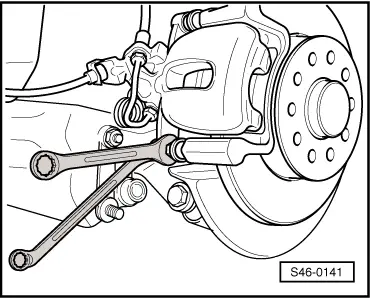

Shock absorber to wheel-bearing housing

| 180 Nm | ||

Brake caliper to brake carrier

| 35 Nm | ||

| Wheel speed sensor | 8 Nm | ||

| Wheel bolts | 120 Nm |

WARNING

WARNING