|

Timing, Check

Remove Remove

Remove air cleaner housing with air intake hose and hot film

mass air flow meter – see illustration "Air Ducts".

Remove upper part of toothed belt cover – see operation

"Toothed Belt Cover – Upper Part, Remove and Install".

For version with AC: Remove ribbed V-belts – see operation

"Ribbed V-belts, Remove and Install".

Remove V-belt – see operation "V-belt, Remove and

Install".

Remove lower part of toothed belt cover – see operation

"Toothed Belt Cover – Lower Part, Remove and Install".

Check toothed belt tension, adjust if necessary – see

operation "Toothed Belt Tension, Check".

|

Remove engine vent hose from camshaft housing cover.

Remove camshaft housing cover from camshaft housing.

Adjust Adjust

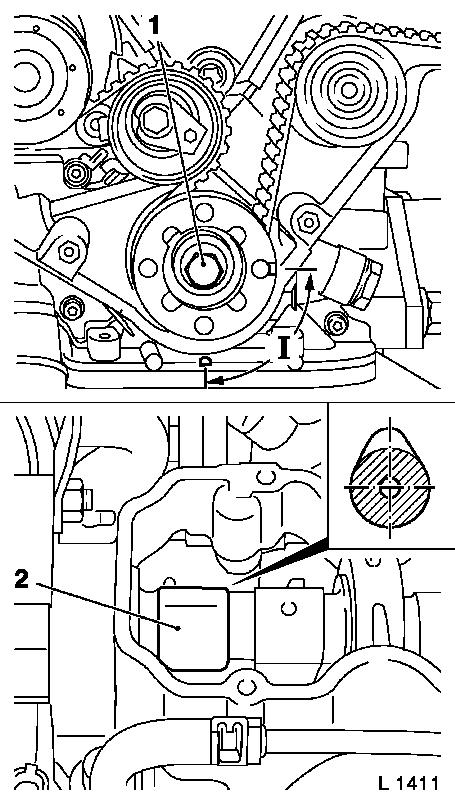

At fastening bolt (1) of toothed belt drive gear, turn

crankshaft in engine rotational direction to approx. 90°

(dimension I) before "1st cylinder TDC".

Inspect

Inspect

1st cylinder exhaust cam (2) must point vertically upwards.

|

|

Install

Install

|

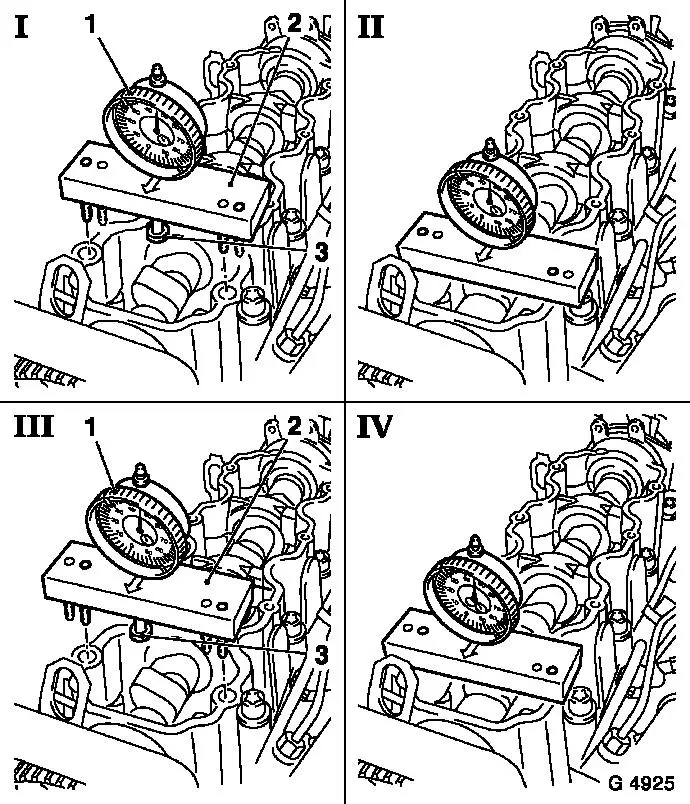

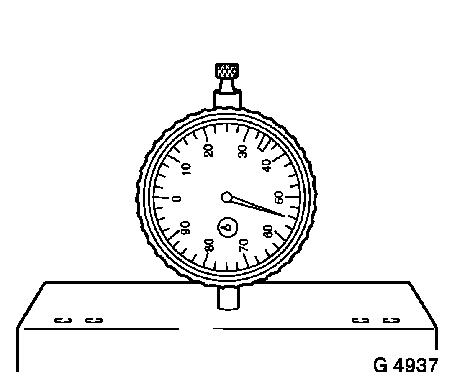

Insert Dial gauge MKM-571-B (1) in Tool KM-661-1 (2) –

arrow on KM-661-1 points towards engine timing side. Attach base

(3) Ø 10 mm to dial gauge. To adjust dial gauge, left

positioning pins of tool (I+II) must be seated in bores of camshaft

housing. Set probe of dial gauge onto basic circle of 2nd cam

(intake, 1st cylinder). Set dial gauge to "0" – ensure that

the probe is not seated on the cam oil bore.

Caution

The Dial Gauge MKM-571 may be pre-tensioned by max. 0.5 mm,

otherwise the resulting measurement will be incorrect.

Offset Tool KM-661-1 with dial gauge to the left. Right

positioning pins (III+IV) must be seated in the bores of the

camshaft housing.

|

|

|

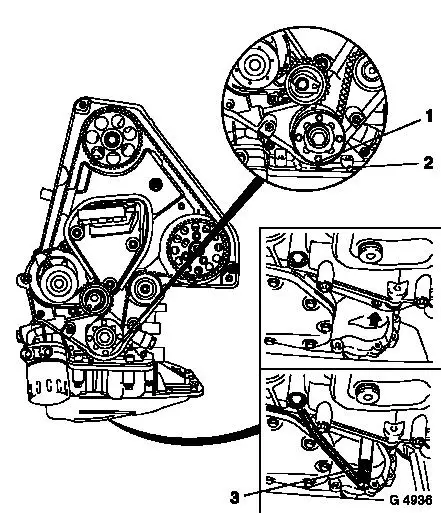

At fastening bolt of toothed belt drive gear, turn crankshaft in

engine rotational direction to just before "1st cylinder ignition

TDC". Insert TDC Centring Pin KM-951 (3) into opening on

transmission (arrow), at the same time at fastening bolt of toothed

belt drive gear, further turn crankshaft in engine rotational

direction until TDC centring pin engages in cylinder block or

crankshaft webs to the stop.

Inspect

Inspect

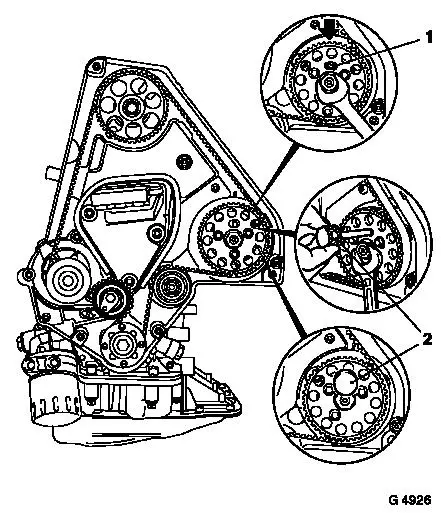

In this position, mark (1) on toothed belt drive gear must align

with mark (2) on oil pump.

Note: Attach to

flywheel side with the engine removed or unflanged Transmission

KM-540-A.

|

|

Install

Install

|

Mark out injection pump with Marker Pin KM-6011 (2).

Caution

With open-ended spanner turn injection pump flange until recess

(1) on injection pump pulley aligns with injection pump flange

recess and injection pump retaining bore (arrow).

Note: If the marker

pin could not be inserted then a basic adjustment must be performed

– see operation "Timing, Adjust".

|

|

Measure

Measure

|

Read off value on Dial Gauge MKM-571-B.

Camshaft elevation nominal value: 0.55 mm ± 0.03 mm.

Note: If the measured

result does not agree with the nominal value, adjust timing –

see operation "Timing, Adjust".

Remove Remove

Remove all retaining and adjusting tools.

|

|

Install

Install

Install camshaft housing cover with new gasket to camshaft

housing – tightening torque – 8 Nm / 6 lbf. ft.

Attach engine bleeding hose to camshaft housing cover.

Install lower part of toothed belt cover – see operation

"Toothed Belt Cover – Lower Part, Remove and Install".

Install V-belt – see operation "V-belt, Remove and

Install".

For version with AC: Install ribbed V-belt – see operation

"Ribbed V-belt, Remove and Install".

Install upper part of toothed belt cover – see operation

"Toothed Belt Cover – Upper Part, Remove and Install".

Install air cleaner housing with air intake hose and hot film

mass air flow meter – see illustration "Air Ducts".

|