|

Pressure Loss, Check

Remove Remove

Remove glow plugs – see operation "Glow Plugs, Remove and

Install".

Remove vacuum pump – see operation "Vacuum Pump, Remove

and Install".

|

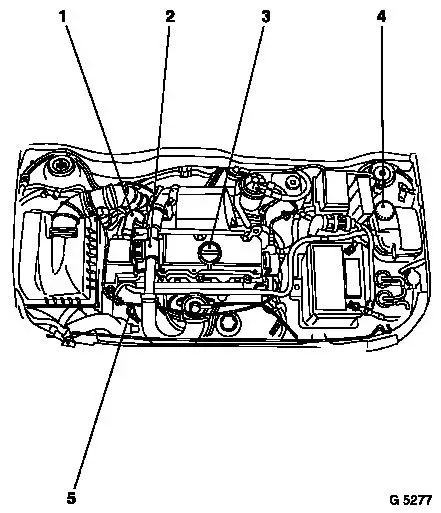

Detach engine vent hose (1) from cylinder head cover.

For X 20 DTL, Y 20 DTL engines: Remove charge air pipe (2) with

charge air hose.

Detach closure caps from oil filler aperture (3) and from

coolant compensation tank (4).

Remove oil dipstick (5) from oil dipstick guide tube.

|

|

Adjust Adjust

|

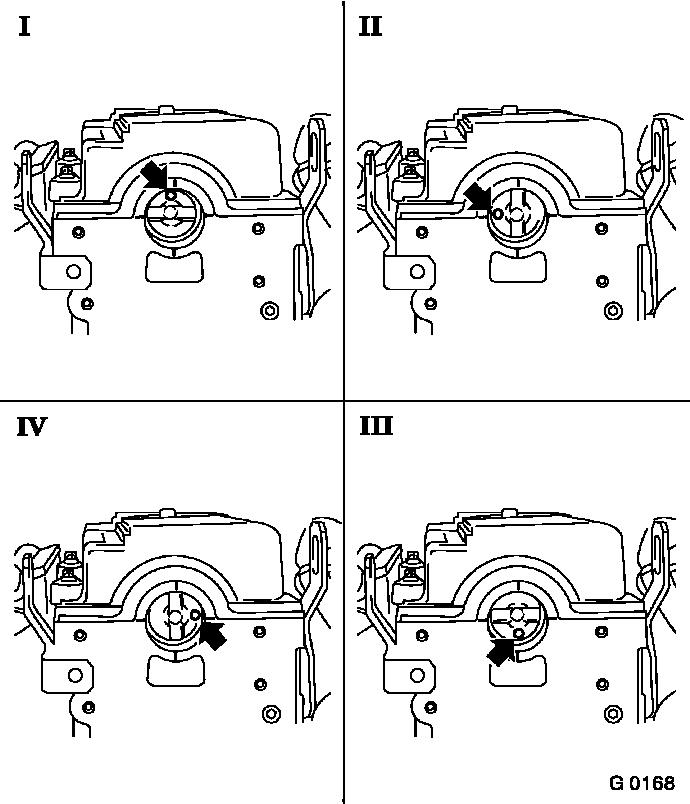

At fastening bolt of the torsional vibration damper, turn the

crankshaft in engine rotational direction to TDC of the cylinder

being checked.

Bore (arrow) on the camshaft must align

with the relevant guide mark.

- TDC for 1st cylinder.

- TDC for 3rd cylinder.

- TDC for 4th cylinder.

- TDC for 2nd cylinder.

|

|

Caution

The crankshaft is not permitted to rotate during the test

procedure. In order to avoid this, engage 1st gear or selector

lever position "P" and apply parking brake.

|

Install

Install

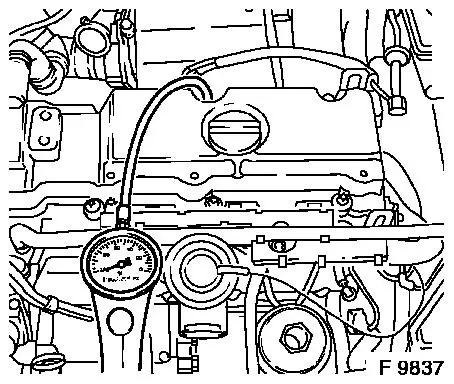

Connect pressure loss tester to compressed air system and

calibrate (observe manufacturer's instructions).

Bolt pressure loss tester in conjunction with Adapter KM-533-B

and Connecting Piece KM-928 into glow plug bore hole.

|

|

Inspect

Inspect

Read off pressure loss on tester as a percentage. At the same

time, pay attention to any audible deviations in the compressed air

at intake manifold, turbocharger, exhaust system, glow plug bore

holes and crankcase as well as to any bubble formation in the

coolant compensation tank.

Max. permissible pressure loss difference between the individual

cylinders approx. 10 %. The max. pressure loss of one cylinder

should not exceed 25 %

Remove Remove

Remove pressure loss tester with adapter and connector.

Install

Install

Attach closure caps to oil filler aperture and coolant

compensation tank.

Insert oil dipstick into oil dipstick guide tube.

For X 20 DTL, Y 20 DTL engines: Install charge air hose and

charge air pipe with new seal ring – tightening torque 3.5 Nm

/ 2.6 lbf. ft.

Attach engine vent hose to cylinder head cover.

Install vacuum pump – see operation "Vacuum Pump, Remove

and Install".

Install glow plugs – see operation "Glow Plugs, Remove and

Install".

|