|

Camshaft and Cam Follower, Remove and Install

(Cylinder Head Installed)

Remove Remove

Remove battery support – see operation "Battery Support,

Remove and Install" in group "A".

Remove air cleaner housing with air intake cover – see

illustration "Air Ducts (X 16 SZR)" and illustration "Air Ducts (Z

16 SE)".

Remove upper part of toothed belt cover – see operation

"Toothed Belt Cover – Upper Part, Remove and Install".

Remove ribbed V-belts – see operation "Ribbed V-belts,

Remove and Install".

Remove ribbed V-belt tensioner – see operation "Ribbed

V-belt Tensioner, Remove and Install".

Remove lower part of toothed belt cover – see operation

"Toothed Belt Cover – Lower Part, Remove and Install".

|

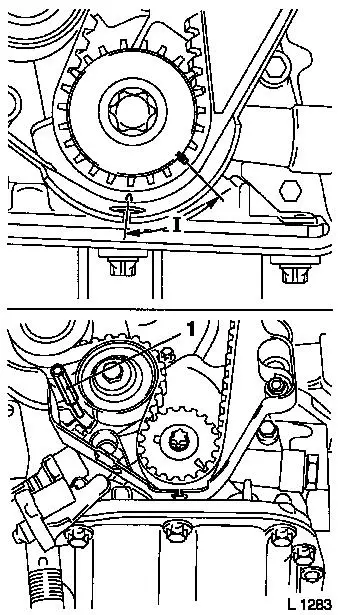

Caution

Before removing the toothed belt – screw fastening bolt of

the torsional vibration damper into crankshaft and position

crankshaft in direction of engine rotation 60° (dimension I) in

front of TDC mark.

Remove Remove

Move toothed belt tension roller upwards against spring force at

tension roller base plate until bore holes align and fix toothed

belt tension roller in place with suitable drift (1).

|

|

Remove toothed belt from camshaft pulley.

Remove camshaft pulley – see operation "Seal Ring in Front

Camshaft Housing, Replace".

Remove DIS ignition module – see operation "DIS Ignition

Module, Remove and Install".

Remove carrier plate from camshaft housing – see operation

"Seal Ring in Rear Camshaft Housing, Replace".

|

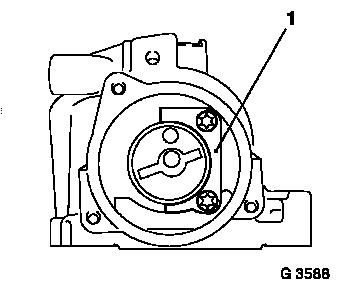

Remove pressure plate (1) from camshaft housing.

Caution

Cover oil return bore holes in cylinder head during assembly so

thrust pieces cannot fall in.

|

|

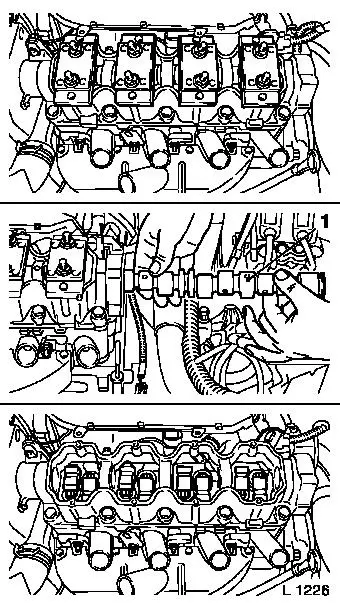

Remove Remove

|

Attach Valve Lifter Depressor MKM-891 to camshaft housing.

Uniformly compress all cam followers. Pull camshaft (1) out of

camshaft housing. Release valve lifter depressor and remove from

camshaft housing. Remove cam followers and thrust pieces –

lay aside in installation position and note layout.

Inspect

Inspect

Check all parts for damage and wear and replace if necessary.

When replacing camshaft all cam followers must be replaced. Prior

to installation ensure that crankshaft is 60° before TDC

mark.

Install

Install

Insert thrust pieces and cam followers – note installation

position and allocation. Attach valve lifter depressor onto

camshaft housing and press down all cam followers uniformly. Coat

sliding surfaces with MoS 2 lubricating

paste (grey). Insert camshaft in camshaft housing.

|

|

Install pressure plate on camshaft housing – 8 Nm / 6 lbf.

ft.

Remove Remove

Release tension in valve lifter depressor and remove from

camshaft housing.

Install

Install

Attach carrier plate to camshaft housing – see operation

"Seal Ring in Rear Camshaft Housing, Replace".

Attach DIS ignition module – see operation "DIS Ignition

Module, Remove and Install".

Install camshaft pulley – see operation "Seal Ring in

Front Camshaft Housing, Replace".

Caution

Prior to installation of toothed belt, marks on toothed belt

drive gear and oil pump housing, as well as notches on camshaft

pulley and rear toothed belt cover, must align – see

operation "Timing, Adjust".

Install toothed belt – see operation "Toothed Belt, Remove

and Install".

Remove fastening bolt from toothed belt drive gear and install

toothed belt cover, lower part – see operation "Toothed Belt

Cover, Lower Part, Remove and Install".

Install ribbed V-belt tensioner – see operation "Ribbed

V-belt Tensioner, Remove and Install".

Install ribbed V-belt – see operation "Ribbed V-belt,

Remove and Install".

Install upper part of toothed belt cover – see operation

"Toothed Belt Cover – Upper Part, Remove and Install".

Install air cleaner housing with air intake cover – see

illustration "Air Ducts (X 16 SZR)" and illustration "Air Ducts (Z

16 SE)".

Install battery support – see operation "Battery Support,

Remove and Install" in group "A".

|