Piston, Connecting Rod, and Bearing Replacement

Special Tools

EN-46785 Fixing Tool

For equivalent regional tools, refer to

Special Tools .

Removal Procedure

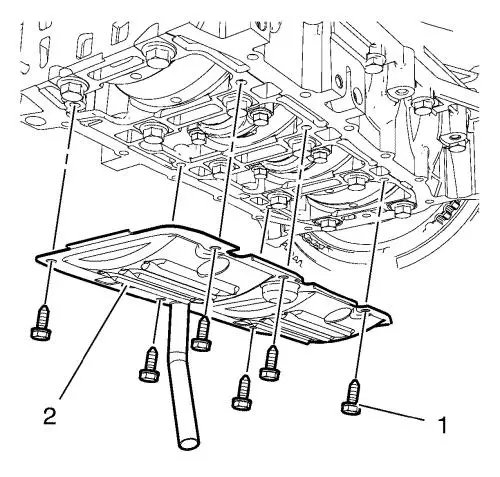

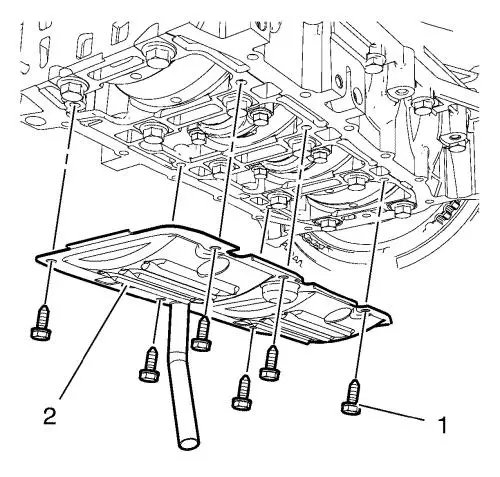

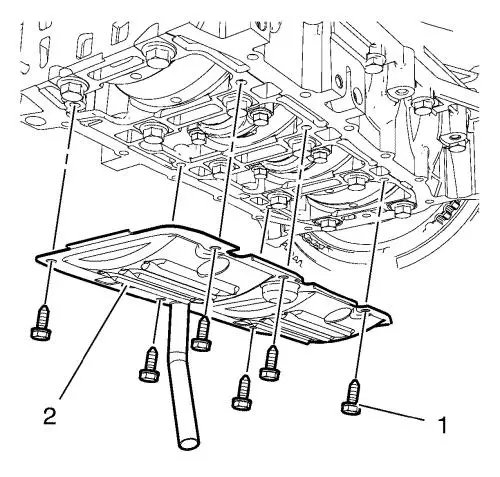

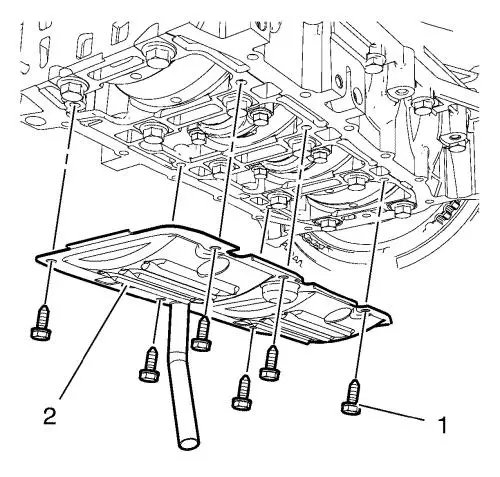

| 4. |

Remove the 6 oil pan baffle

bolts (1). |

| 5. |

Remove the oil pan baffle

(2). |

|

Note: If the

EN-46785 fixing tool is installed, remove it.

|

| 6. |

Set the crankshaft to TDC of

combustion stroke of cylinder 1. |

| 7. |

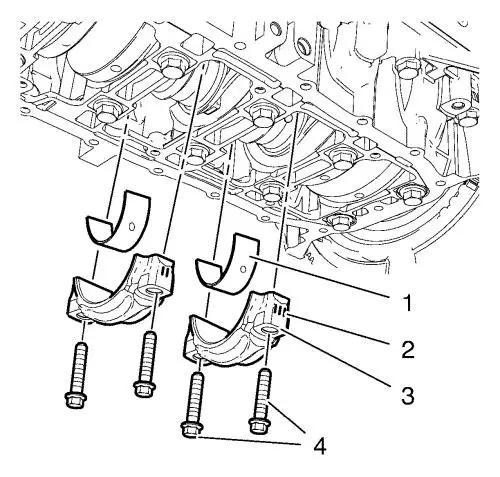

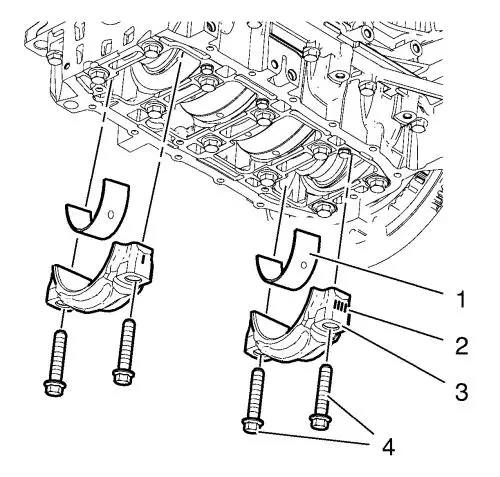

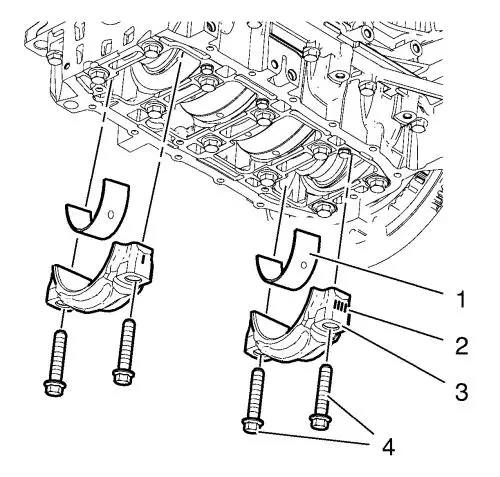

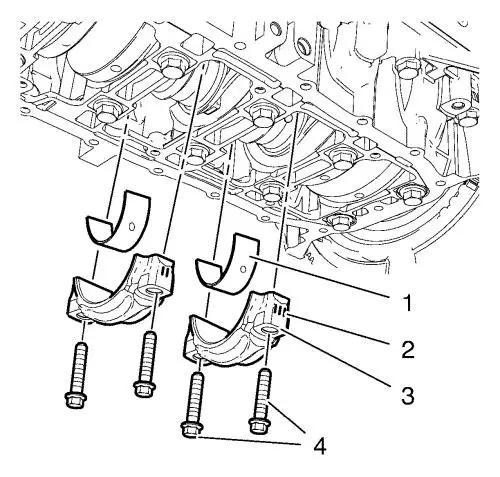

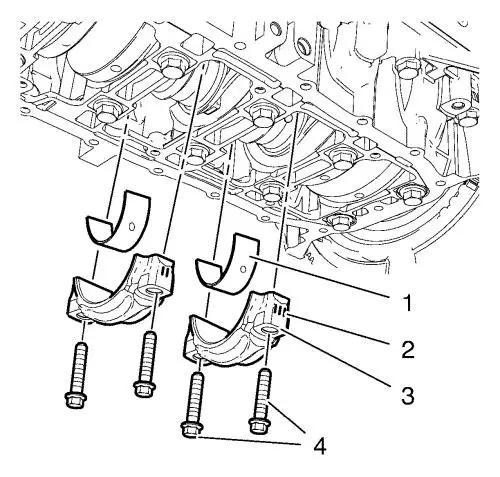

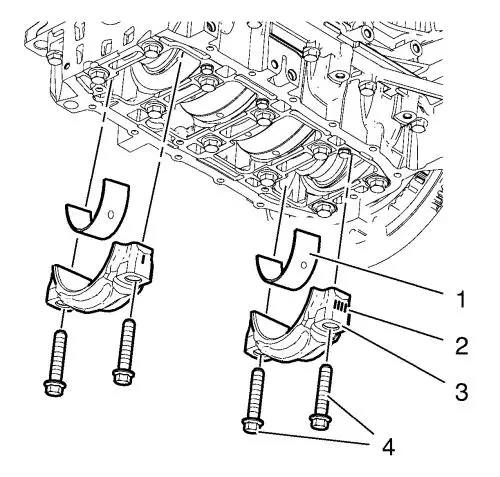

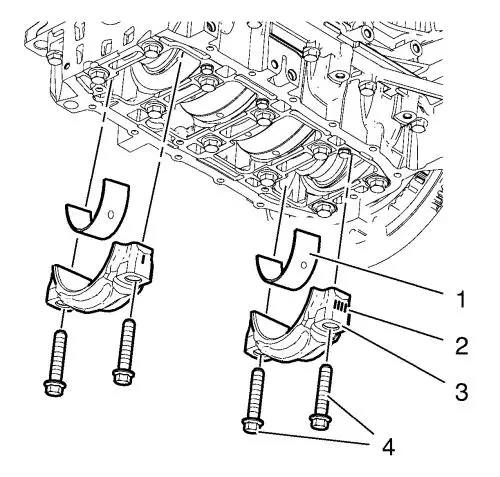

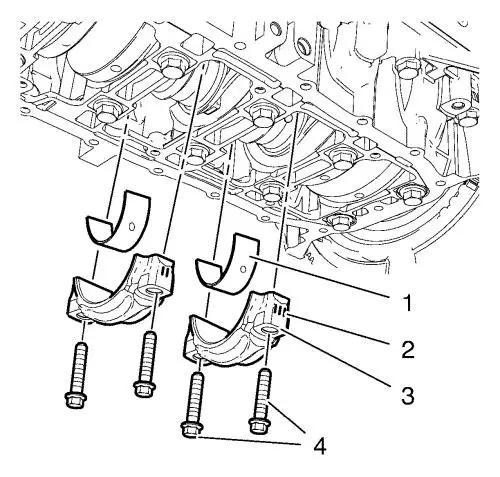

Remove and DISCARD the 4

connecting rod bearing cap bolts (4) from the cylinder 2 and

3. |

|

Note: Marking (2) of

the connecting rod bearing caps. Set aside in the order

removed.

|

|

Note: The shear

surfaces of the connecting rod and the connecting rod bearing cap

form a unique fit and must not be swapped or damaged. Do not lay

down on the shear surfaces.

|

| 8. |

Remove the 2 connecting rod

bearing caps (3) from the cylinder 2 and 3. |

|

Note: Set aside in

the order removed.

|

| 9. |

Remove the 2 connecting rod

lower bearings (1). |

|

Note: Marking (2) of

the connecting rod. Set aside in the order removed.

|

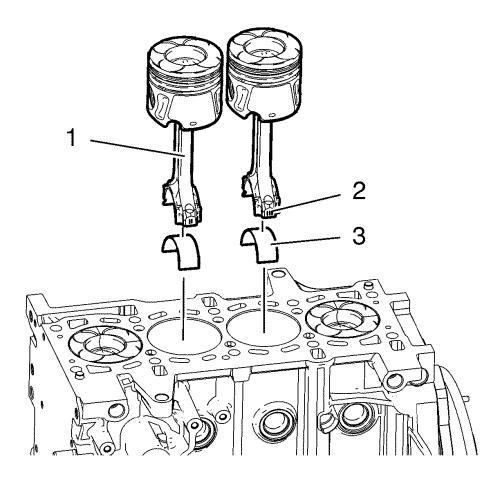

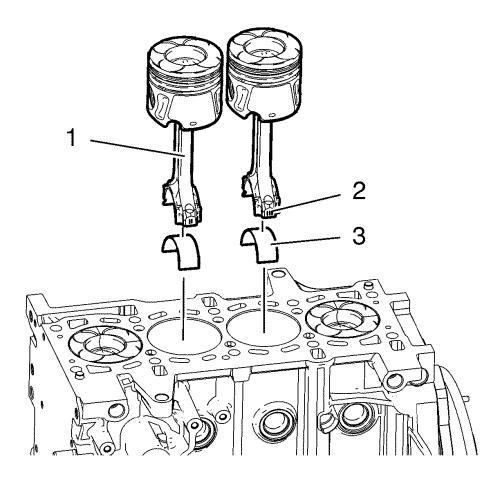

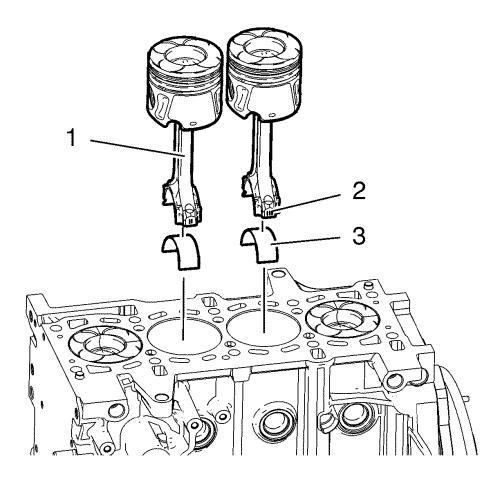

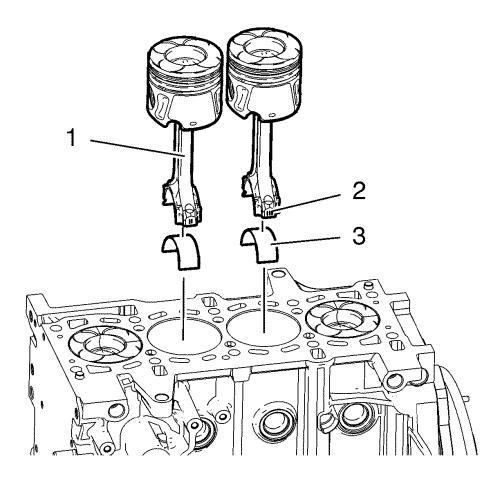

| 10. |

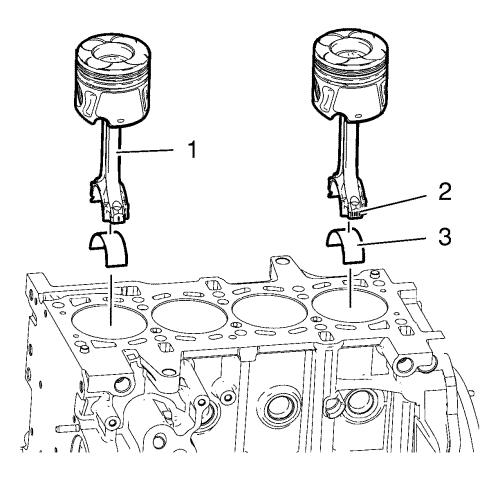

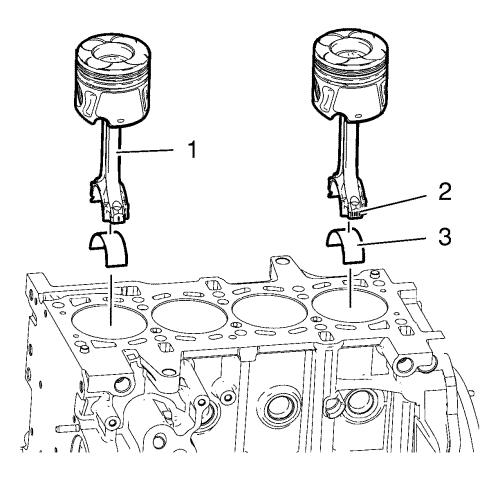

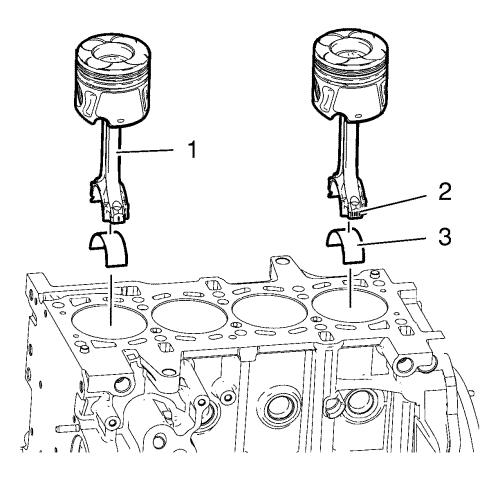

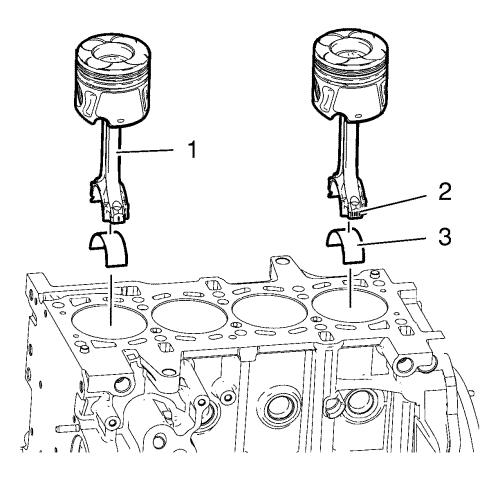

Push the 2 pistons with

connecting rod (1) from the cylinder 2 and 3 upwards. |

| 11. |

Remove the 2 connecting rod

upper bearings (1) from the cylinder 2 and 3. |

| 12. |

Turn the crankshaft through

180° and set crankshaft to TDC of combustion

stroke of cylinder 2. |

| 13. |

Remove and DISCARD the 4

connecting rod bearing cap bolts (4) from the cylinder 1 and

4. |

|

Note: Marking (2) of

the connecting rod bearing caps. Set aside in the order

removed.

|

|

Note: The shear

surfaces of the connecting rod and the connecting rod bearing cap

form a unique fit and must not be swapped or damaged. Do not lay

down on the shear surfaces.

|

| 14. |

Remove the 2 connecting rod

bearing caps (3) from the cylinder 1 and 4. |

|

Note: Set aside in

the order removed.

|

| 15. |

Remove the 2 connecting rod

lower bearings (1). |

|

Note: Marking (2) of

the connecting rod. Set aside in the order removed.

|

| 16. |

Push the 2 pistons with

connecting rod (1) from the cylinder 1 and 4 upwards. |

|

Note: Set aside in

the order removed.

|

| 17. |

Remove the 2 connecting rod

upper bearings (3) from the cylinder 1 and 4. |

Installation Procedure

|

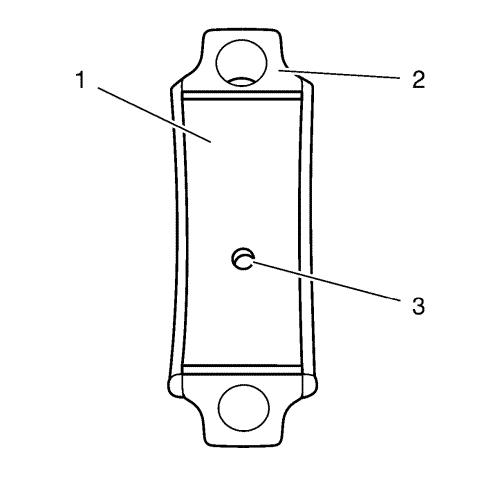

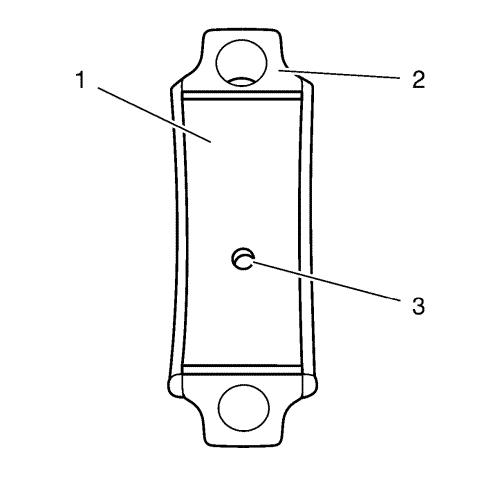

Note: Install the 4

connecting rod bearing shells with oil bore (3) into the connecting

bearing caps (2).

If the old connecting rod bearing shells will be reused,

install in their original position.

|

| 2. |

Install the 8 connecting rod

bearing shells (1). |

| 3. |

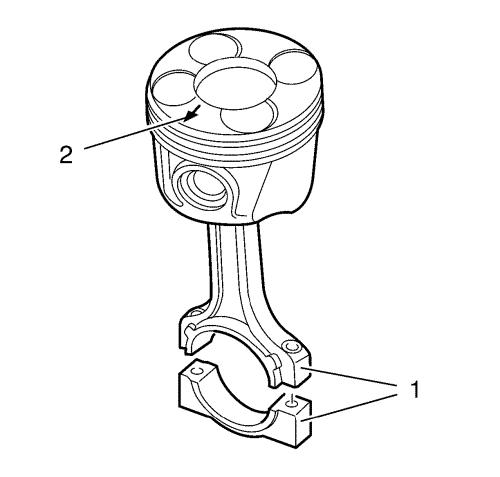

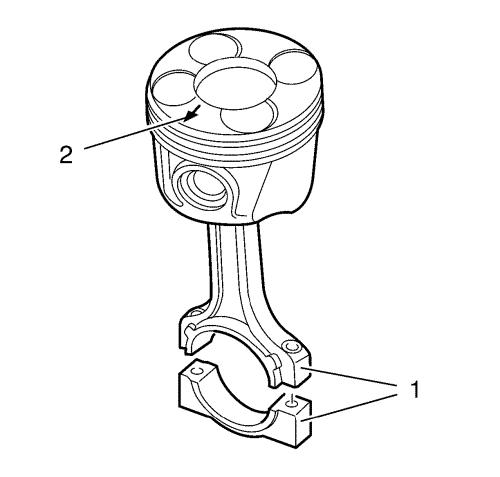

The arrow (2) on the piston

head must point to the timing side. |

|

Note: The connecting

rod bearing caps must be installed in their original position.

|

| 4. |

Note the marking (1) of the

connecting rod and connecting rod cap. |

| 5. |

The piston ring joints must be

displaced 120° to each other. |

| 6. |

Set the crankshaft to TDC of

combustion stroke of cylinder 2. |

| 7. |

Coat all pistons and cylinder

bores with engine oil. |

| 8. |

Install a piston ring

compressor in order to compress the piston rings. |

| 9. |

Install the 2 pistons with

connecting rod (1) and connecting rod upper bearing shells (3) into

cylinder 1 and 4. |

|

Note: Marking (2) of

the connecting rod bearing caps.

|

| 10. |

Install the 2 connecting rod

bearing caps (3) with connecting rod lower bearing shells (1) into

cylinder 1 and 4. |

| 11. |

Install 4 NEW connecting rod

bearing cap bolts (4) to cylinder 1 and 4 and tighten in following

order: |

| |

• |

Tighten the bolts in first

step to 20 N·m (15 lb ft) . |

| |

• |

Tighten the bolts to an

additional 40° . |

| 12. |

Turn the crankshaft through

180° and set crankshaft to TDC of combustion

stroke of cylinder 1. |

| 13. |

Install a piston ring

compressor in order to compress the piston rings. |

| 14. |

Install the 2 pistons with

connecting rod (1) with connecting rod upper bearing shells (3)

into cylinder 2 and 3. |

|

Note: Marking (2) of

the connecting rod bearing caps.

|

| 15. |

Install the 2 connecting rod

bearing caps (3) with the connecting rod lower bearing shells (1)

into cylinder 2 and 3. |

| 16. |

Install 4 NEW connecting rod

bearing cap bolts (4) to the cylinder 2 and 3 and tighten in

following order: |

| |

• |

Tighten the bolts in first

step to 20 N·m (15 lb ft) . |

| |

• |

Tighten the bolts to an

additional 40° . |

| 17. |

Install the oil pan baffle

(2). |

| 18. |

Install the 6 oil pan baffle

bolts (1) and tighten to 9 N·m (80 lb in)

. |

|