Cylinder Head Replacement

Special Tools

| • |

CH-49290

Mounting Engine / Transmission |

| • |

EN-45059

Torque Angle Sensor Kit |

For equivalent regional tools, refer to

Special Tools .

Removal Procedure

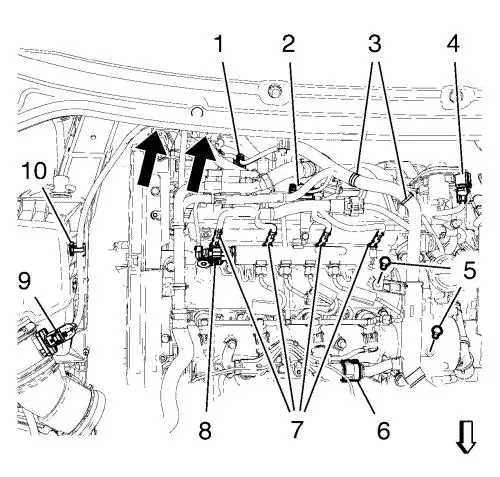

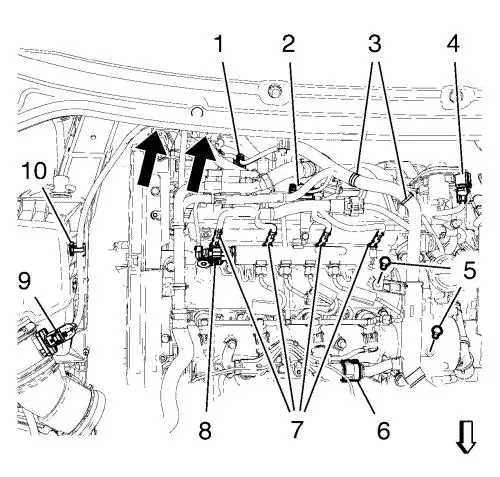

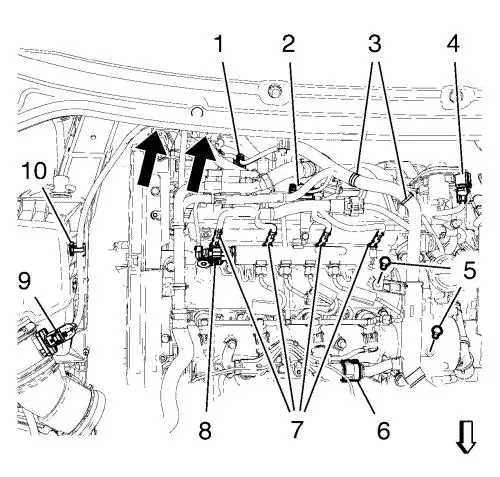

| 4. |

Remove the 2 conduit bolts

(5). |

| 5. |

Disconnect following

connections: |

| |

• |

from the 4 glow plugs

(7) |

| |

• |

from manifold pressure sensor

(2) |

| |

• |

from fuel injection pump

(1) |

| |

• |

from air mass sensor

(9) |

| 6. |

Remove the wiring harness

retainer (10) from the air filter assembly and from the bracket

(see arrows in picture). |

| 7. |

Hang the wiring harness

aside. |

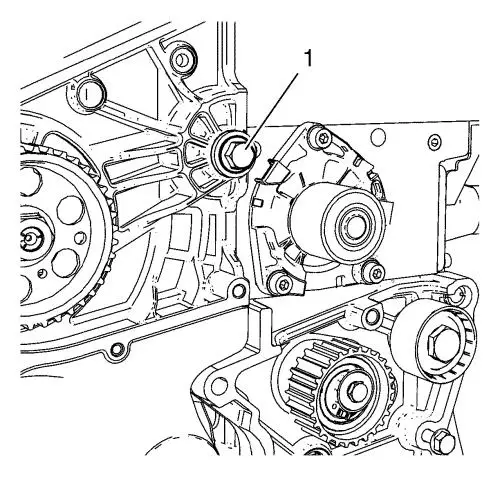

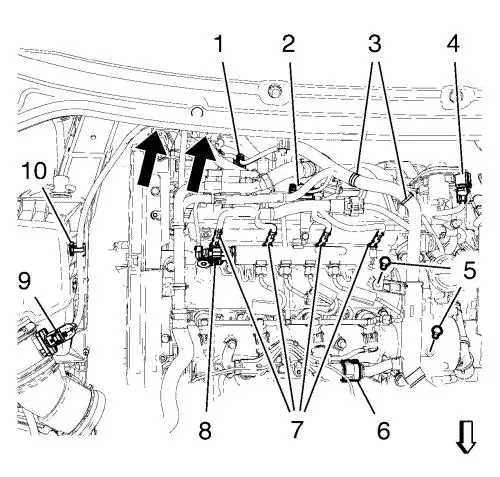

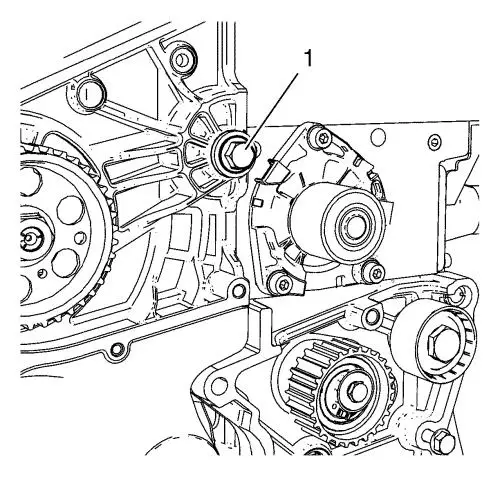

| 16. |

Install the CH-49290

mounting , for the assembly use attached installation

manual. |

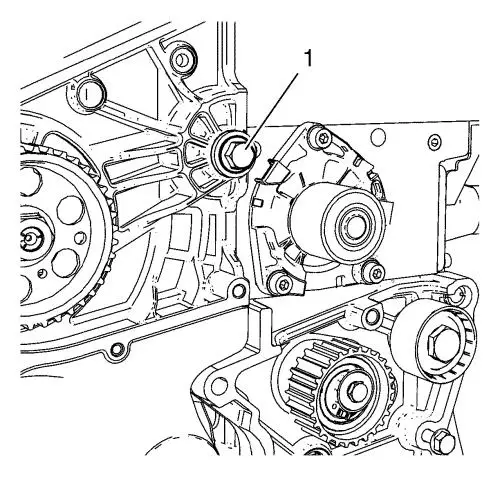

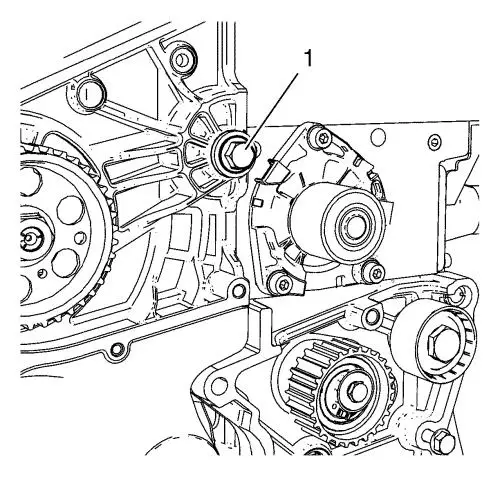

| 18. |

Remove the fuel injection pump

bracket bolt (1). |

| 19. |

Remove the upper positive

crankcase ventilation oil separator bolt. |

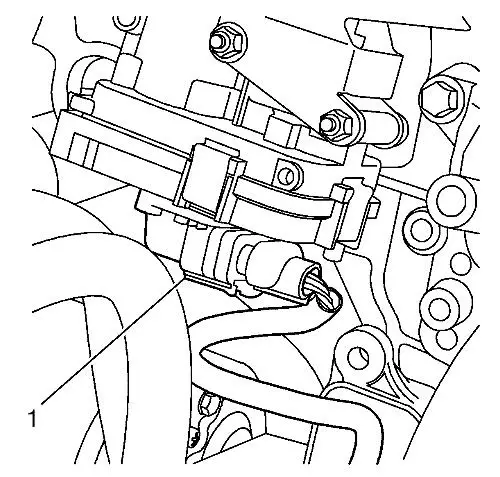

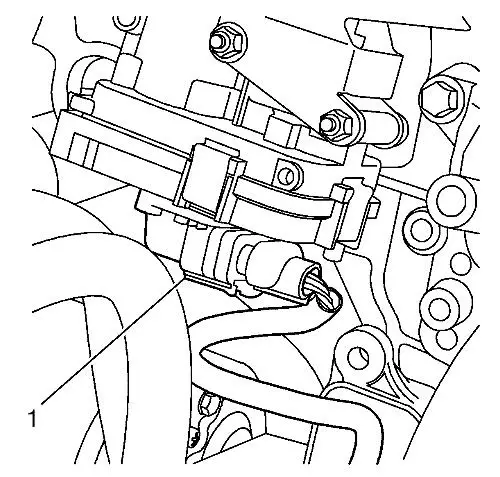

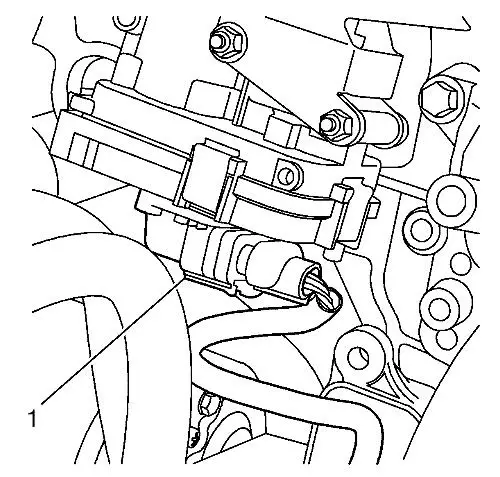

| 22. |

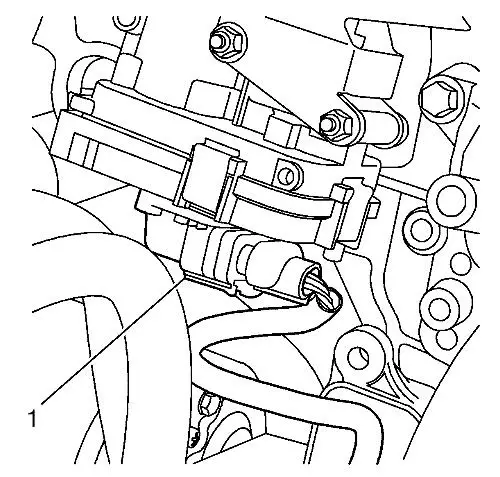

Disconnect the wiring harness

plug (1) from the manifold actuator. |

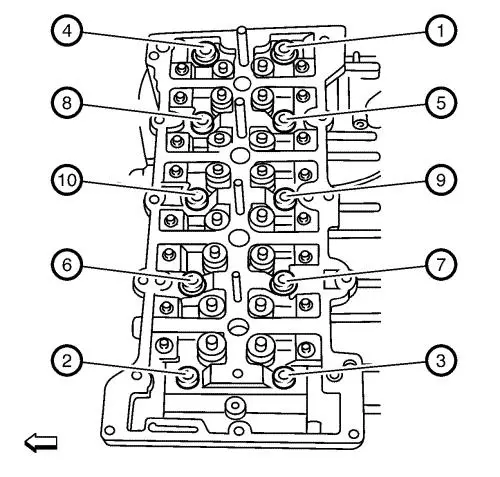

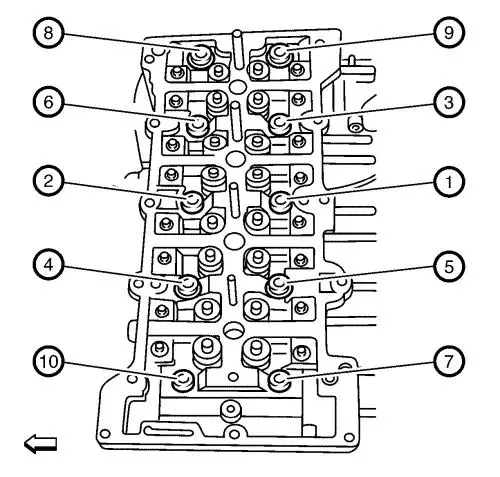

| 24. |

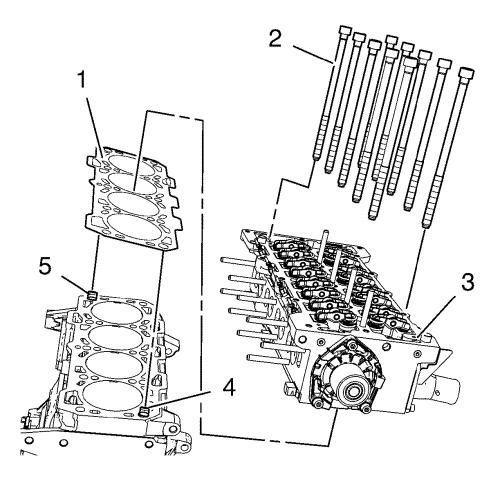

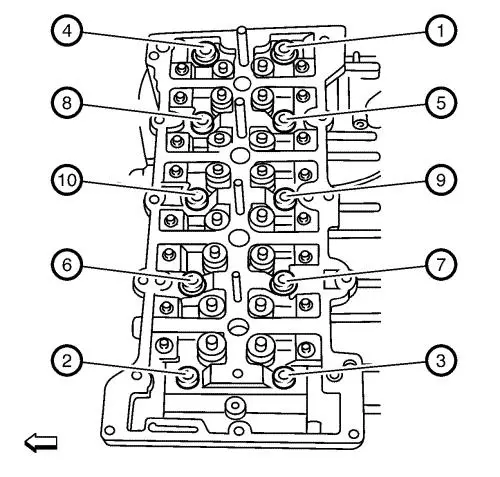

Loosen the 10 cylinder head

bolts in the sequence as shown. Use the following procedure:

|

| |

24.1 |

Loosen the cylinder head bolts

90° . |

| |

24.2 |

Loosen the cylinder head bolts

180° . |

|

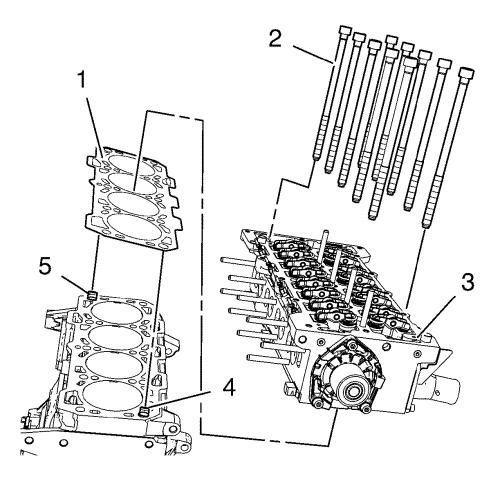

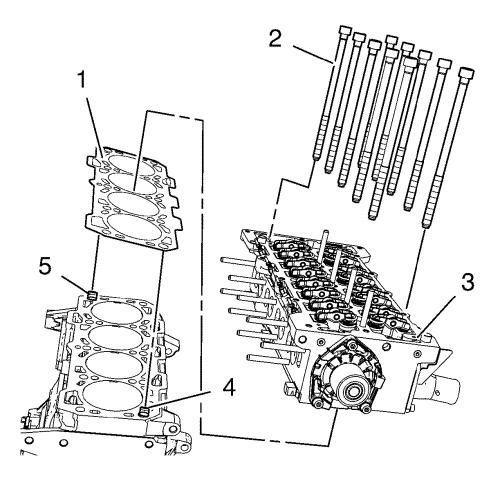

Note: Do not damage

the guide sleeves (4) and (5).

|

| 25. |

Remove and DISCARD the 10

cylinder head bolts (2). |

| 26. |

Remove the cylinder head

(3). |

| 27. |

Remove the cylinder head

gasket (1). |

| 28. |

Remove the assembly parts from

the cylinder head: |

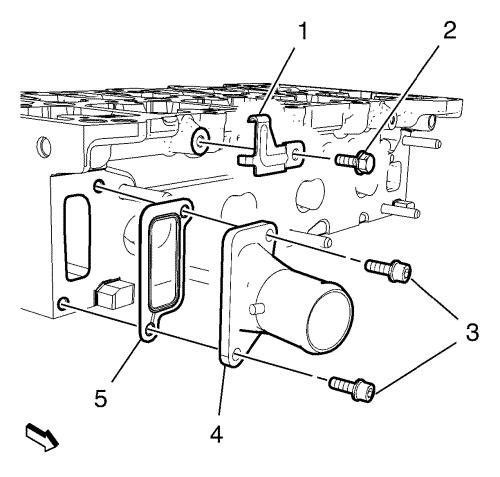

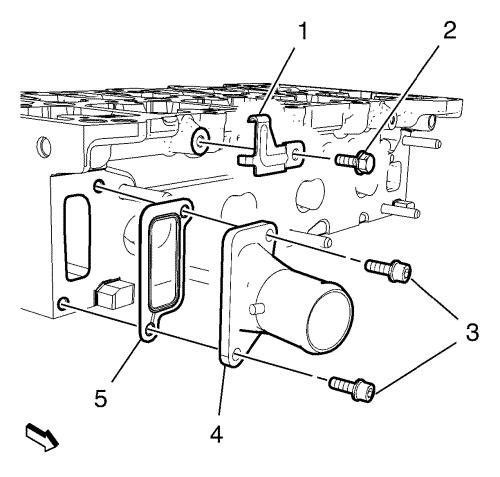

| 29. |

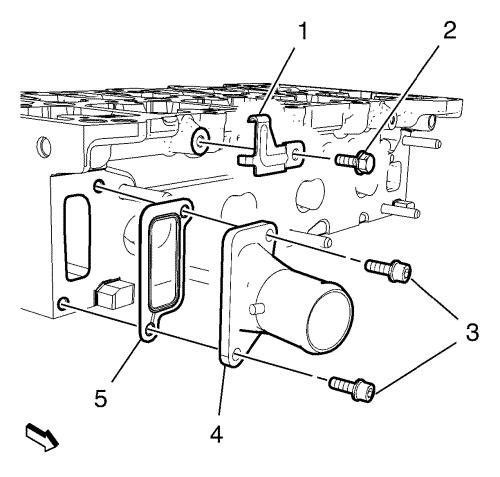

Remove the bracket bolt (2)

and the bracket (1). |

| 30. |

Remove the water outlet bolts

(3). |

| 31. |

Remove the water outlet (4) in

conjunction with the water outlet gasket (5). |

Installation Procedure

|

Caution: Clean all dirt, debris, and coolant from the engine block

cylinder head bolt holes. Failure to remove all foreign material

may result in damaged threads, improperly tightened fasteners or

damage to components. |

|

Note:

| • |

Do not use the

cylinder head bolts again. Install NEW cylinder head bolts during

assembly. |

| • |

Do not use any

type of sealant on the cylinder head gasket, unless

specified. |

| • |

The cylinder head

gaskets must be installed in the proper direction and

position. |

|

| 1. |

Clean the sealing surfaces and

remove all remains of dirt and old gasket material from thread

bores, water galleries and oil galleries. |

| 2. |

Check the flatness of the

cylinder head and cylinder block with a steel rule and inspect for

damage to the sealing surfaces. |

| 3. |

Install the water outlet (4)

in conjunction with a NEW water outlet gasket (5). |

| 4. |

Install the water outlet bolts

(3) and tighten to 9 N·m (80 lb in)

. |

| 5. |

Install the bracket

(1). |

| 6. |

Install the bracket bolt (2)

and tighten to 9 N·m (80 lb in) .

|

| 7. |

Install the assembly parts

from the cylinder head: |

|

Note: Always take the

same thickness like the old gasket.

|

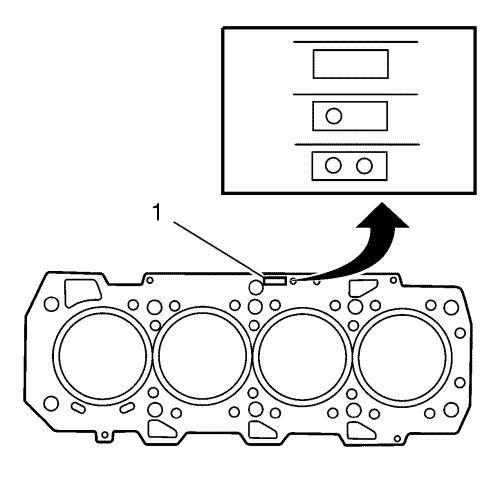

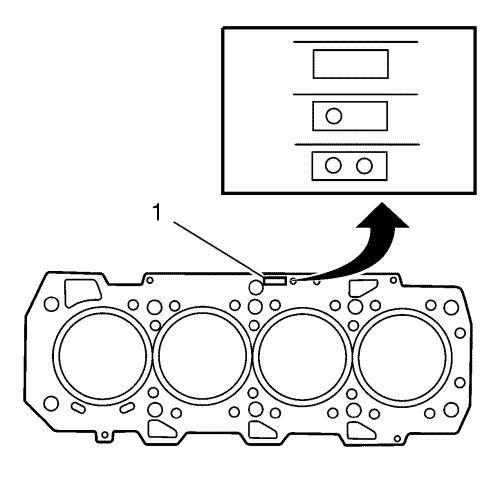

| 8. |

Check the right thickness of

the NEW cylinder head gasket (1). It is marked as shown in

picture: |

| |

• |

without a hole: 0.95

mm (0.0374 in) |

| |

• |

with one hole: 1.05 mm

(0.0413 in) |

| |

• |

with two holes: 1.15

mm (0.0452 in) |

|

Note: Do not damage

the guide sleeves (4) and (5) and do not confuse the engine block

guide sleeves with the camshaft guide sleeves.

|

| 9. |

Install a NEW cylinder head

gasket (1). The marking "Top" should point to the cylinder

head. |

| 10. |

Install the cylinder head

(3). |

| 11. |

Loosely install 10 NEW

cylinder head bolts (2). |

| 12. |

Tighten the 10 NEW cylinder

head bolts in following order: |

|

Note: The following

tightening order applies to ribe cylinder head bolts.

|

| |

12.1 |

First pass in sequence to

20 N·m (15 lb ft) . |

| |

12.2 |

Second pass in sequence to

65 N·m (48 lb ft) . |

| |

12.3 |

Third pass in sequence to an

additional 90° using the EN 45059

angle sensor . |

| |

12.4 |

Fourth pass in sequence to an

additional 90° using the EN 45059

angle sensor . |

| |

12.5 |

Fifth pass in sequence to an

additional 90° using the EN 45059

angle sensor . |

|

Note: The following

tightening order applies to torx T60 cylinder head bolts.

|

| |

12.1 |

First pass in sequence to

20 N·m (15 lb ft) . |

| |

12.2 |

Second pass in sequence to

65 N·m (48 lb ft) . |

| |

12.3 |

Third pass in sequence to an

additional 90° using the EN 45059

angle sensor . |

| |

12.4 |

Fourth pass in sequence to an

additional 90° using the EN 45059

angle sensor . |

| |

12.5 |

Fifth pass in sequence to an

additional 90° using the EN 45059

angle sensor . |

| |

12.6 |

Sixth pass in sequence to an

additional 90° using the EN 45059

angle sensor . |

| 15. |

Connect the wiring harness

plug (1) from the manifold actuator. |

| 17. |

Install the upper positive

crankcase ventilation oil separator bolt and tighten to 9

N·m (80 lb in) . |

| 18. |

Install the fuel injection

pump bracket bolt (1) and tighten to 25 N·m (18 lb

ft) . |

| 20. |

Remove the CH-49290

mounting . |

| 29. |

Install the wiring

harness. |

| 30. |

Connect the following

connections: |

| |

• |

to the 4 glow plugs (7)

|

| |

• |

to manifold pressure sensor

(2) |

| |

• |

to fuel injection pump

(1) |

| 31. |

Install the 2 conduit bolts

(5). |

| 32. |

Install the wiring harness

retainer (10) to the air filter assembly and to the bracket (see

arrows in picture). |

|