|

Piston with Con-rod, Remove and Install

Remove Remove

|

Remove oil pan – see operation "Oil Pan, Remove and

Install".

Remove cylinder head – see operation "Cylinder Head,

Remove and Install".

Remove oil intake pipe.

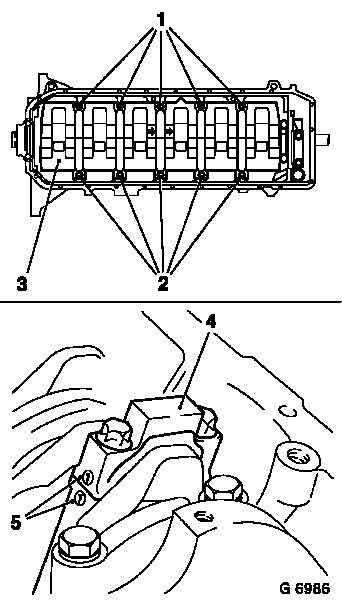

Remove bearing bridge attachment screws (1) and (2). Remove

bearing bridge (3).

Caution

Make note of piston, con-rod and bearing shell installation

positions. Con-rod and con-rod bearing cover (4) are marked with

same pairing number (5).

Clean Clean

Remove oil carbon at upper cylinder edge.

|

|

Remove Remove

|

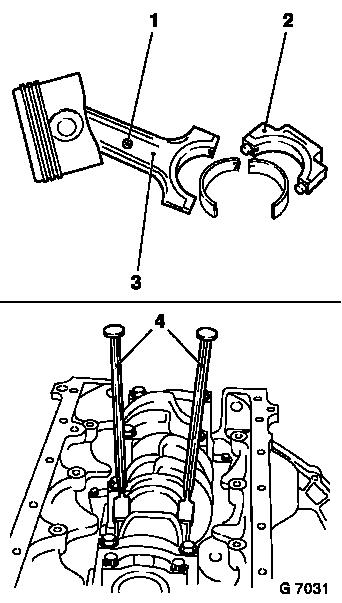

Remove con-rod bearing cover (2) from con-rod (3). Put con-rod

bearing cover and con-rod bearing shells to one side in cylinder

order. Push piston out of the top using con-rod.

Caution

Independently of the colour mark (1), a red and a blue con-rod

bearing shell must be installed per con-rod. The con-rod bearing

shells, blue or red, can be arbitrarily inserted in the con-rod or

in the con-rod bearing caps.

Install

Install

Insert Guide KM-828 (4) into con-rod.

|

|

|

Install

Install

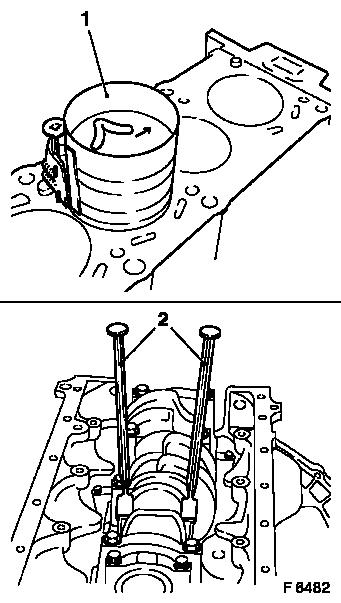

Lightly oil piston and piston rings. Offset piston ring joints

by approx. 120°, but do not position them over the eye of the

piston pin. The piston ring joint of the double-bevelled ring must

be offset 180° to the opening of the inner hose spring.

Compress piston rings with piston ring tensioning band (1).

Arrow on piston head points towards engine timing side. Insert

piston with con-rod.

The crankshaft journal of the relevant cylinder must be in the

"TDC or BDC position".

Entire circumference of piston ring compressor must lie firmly

on cylinder block. Carefully push piston into cylinder using hammer

shaft.

Position piston and con-rod up to the crankshaft journal using

Guide KM-828 (2). Remove Guide KM-828.

|

|

Install

Install

Insert con-rod bearing shells. Note colour code. Con-rod and

con-rod bearing caps are marked with the same pairing number for

identification. Do not mix up.

Install con-rod bearing caps with new bolts at con-rod –

tightening torque 20 Nm / 15 lbf. ft. + 70°.

Attach bearing bridge to cylinder block – tightening

torque 23 Nm / 17 lbf. ft.

Attach oil intake pipe with new oil seal (seal bead facing oil

pump) – tightening torque 11 Nm / 8 lbf. ft.

Install oil pan – see operation "Oil Pan, Remove and

Install".

Install cylinder head – see operation "Cylinder Head,

Remove and Install".

|