|

Tooth Backlash – Balancer Shaft Unit /

Crankshaft, Check and Adjust

Remove Remove

|

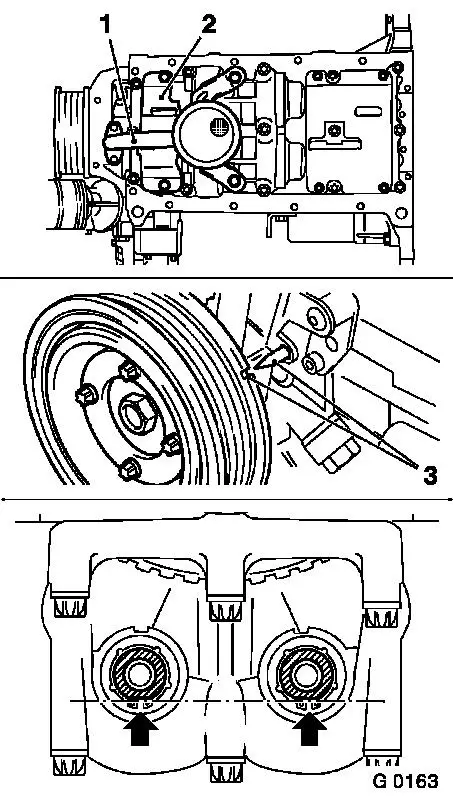

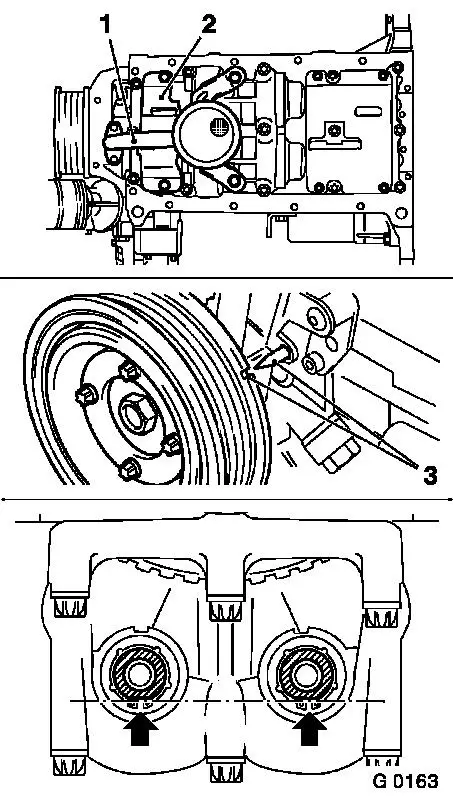

Remove upper part of oil pan – see operation "Oil Pan

– Upper Part, Remove and Install".

Remove oil intake pipe (1) from oil pump and balancer shaft

unit. Separate oil baffle plate (2) from balancer shaft unit.

Adjust Adjust

Turn the crankshaft in the direction of engine rotation to the

mark "1st Cylinder TDC" (3) using the fastening bolt for the

toothed belt drive gear.

In this crankshaft position, the flattened sides (arrows) of

both balancer shafts must point down and form a horizontal

line.

|

|

Install

Install

|

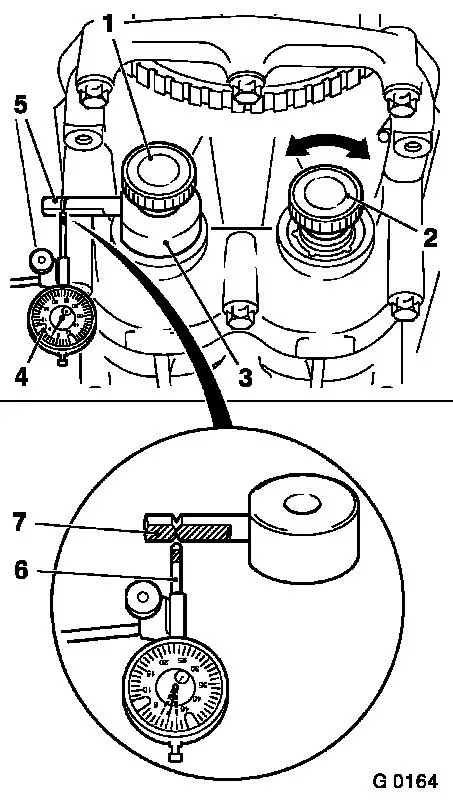

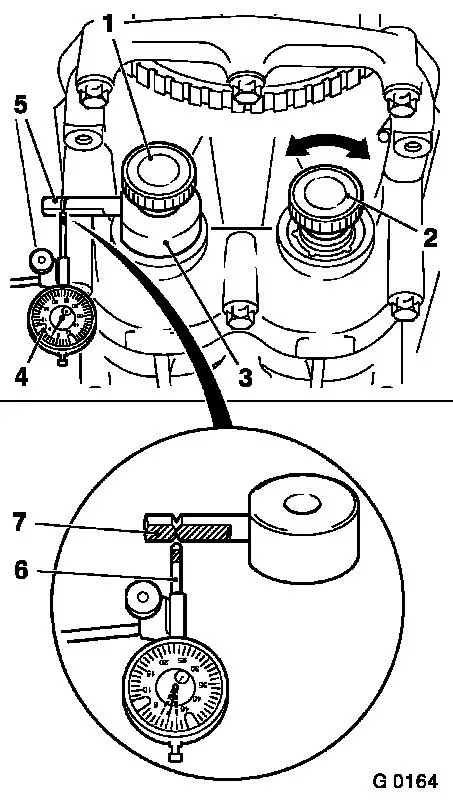

Screw Measuring Device KM-949 (3) with long knurled bolt (1)

into 1st balancer shaft (intake side) and hand-tighten –

measuring arm (5) must point towards "9 o'clock".

Screw short knurled bolt (2) into 2nd balancer shaft (exhaust

side) and also hand-tighten.

Install gauge bracket with Gauge KM-798 (4) to cylinder block

and place probe (6) of gauge against measuring arm of Measuring

Device KM-949 under pre-tension. The probe must be positioned

vertically exactly between the notches on the plane surface

(7).

Determine left and right stop by turning thumb screw (2)

backwards and forwards. Set dial of gauge to zero.

|

|

Measure

Measure

|

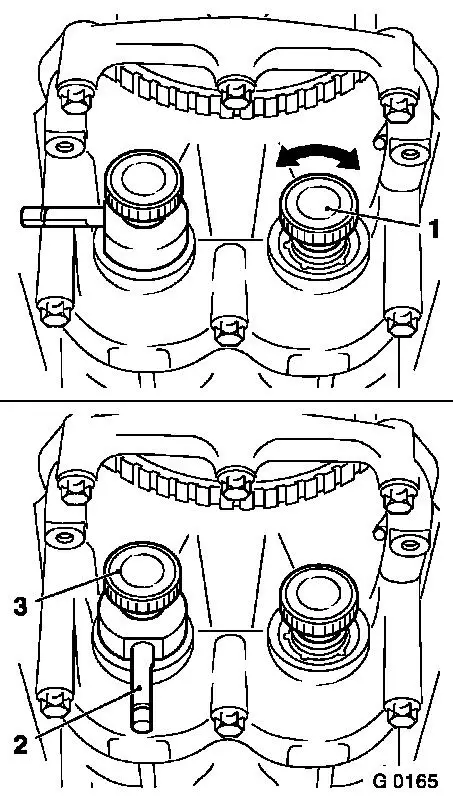

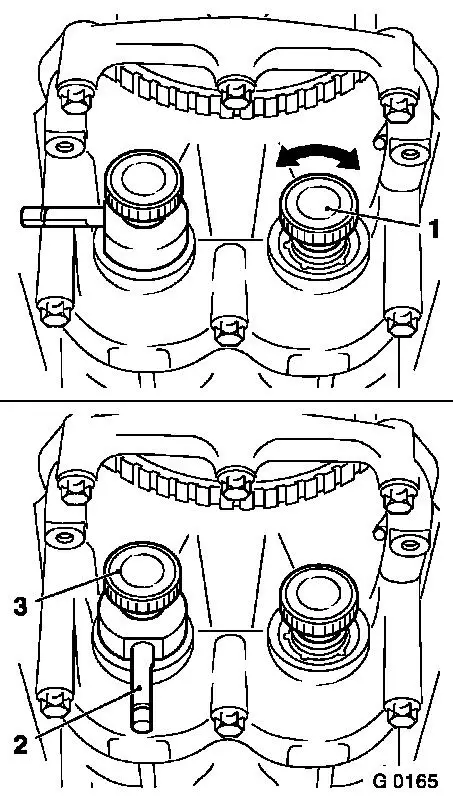

Again use knurled bolt (1) to move 2nd balancer shaft (exhaust

side) back and forth – simultaneously read off tooth backlash

on dial gauge.

Permissible backlash is: 0.02 mm to 0.06 mm.

The tooth backlash must be measured in 4 different positions

– for this, further turn crankshaft at the fastening bolt of

the toothed belt drive gear by 90° in each case in engine

rotational direction until measuring arm (2) is at "6 o'clock".

The loosen the thumb screw (3) and fix measuring arm to "9

o'clock" again and repeat the measurement.

If one of the 4 measurements results in a value outside of the

tolerance range (0.02 mm to 0.06 mm), the tooth backlash must be

adjusted.

|

|

Tooth Backlash – Balancer Shaft Unit /

Crankshaft, Adjust

Remove Remove

Detach balancer shaft unit from

cylinder block / crankshaft bearing cover and remove with balancer

piece. There is an identification number on the balancer piece for

easier allocation. The tooth backlash can also be adjusted using

balancer pieces of varying thickness.

|

Code

|

Thickness of balancer piece in mm

|

|

|

|

|

55

|

0.535 to 0.565

|

|

58

|

0.565 to 0.595

|

|

61

|

0.595 to 0.625

|

|

64

|

0.625 to 0.655

|

|

67

|

0.655 to 0.685

|

|

70

|

0.685 to 0.715

|

|

73

|

0.715 to 0.745

|

|

76

|

0.745 to 0.775

|

|

79

|

0.775 to 0.805

|

|

82

|

0.805 to 0.835

|

|

85

|

0.835 to 0.865

|

Note: The next larger

or smaller balancer piece changes the tooth backlash by approx.

0.02 mm.

Example for selecting the balancer piece: with an installed

balancer piece with the mark "70" a tooth backlash of 0.08 mm was

determined. If a balancer piece with the mark "67" is then

installed, then this produces a tooth backlash of approx. 0.06

mm.

Caution

Only one balancer piece may be installed.

Install

Install

|

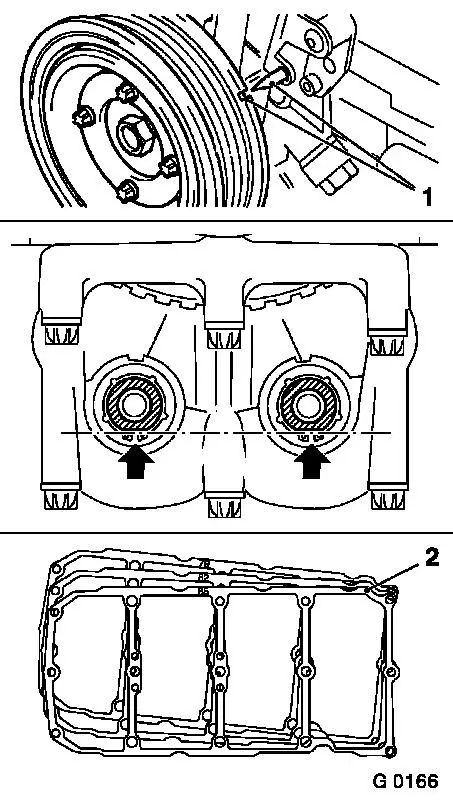

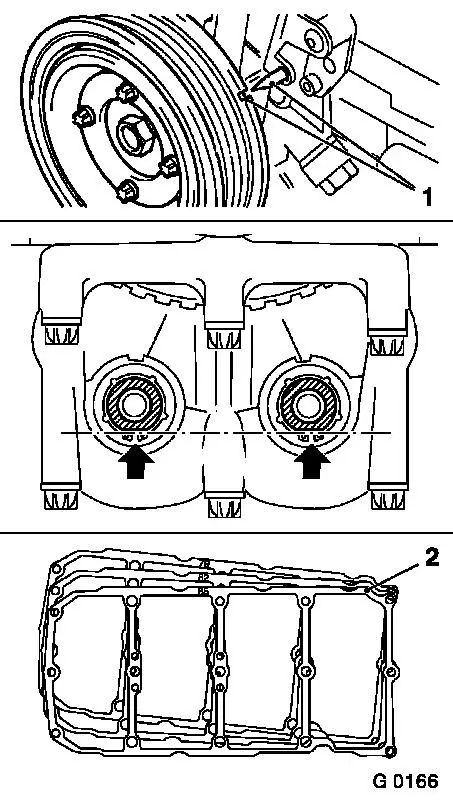

Turn the crankshaft in the direction of engine rotation to the

mark "1st Cylinder TDC" (1) using the fastening bolt for the

toothed belt drive gear.

Turn balancer shafts so that both plane sides (arrows) point

downward and form a horizontal line.

Install selected balancer piece (2) with balancer shaft unit on

cylinder block / crankshaft bearing caps – tighten all

fastening bolts uniformly – tightening torque 20 Nm / 15 lbf.

ft. + 45°.

Measure

Measure

Following installation of balancer shaft unit, tooth backlash

must be re-checked and, if necessary, adjusted.

Note: If the balancer

shaft unit needs to be replaced, use the thickest balancer piece

(identification "85") for the initial installation to ensure a

tooth backlash in any case.

|

|

Install

Install

Attach oil baffle plate to balancer shaft unit.

Attach oil intake pipe with new seal ring to oil pump and insert

fastening bolts with bolt locking compound (red) – tightening

torque 8 Nm / 6 lbf. ft. 1)

.

Attach oil intake pipe bracket to

balancer shaft unit.

|

Bolt M6 – tightening torque 10 Nm / 7.5 lbf. ft.

|

|

Bolt M8 – tightening torque 20 Nm / 15 lbf. ft.

|

Upper part of oil pan – see operation "Oil Pan –

Upper Part, Remove and Install".

1 ) The installation time including torque check is

max. 10 min.

|