Golf Mk1

|

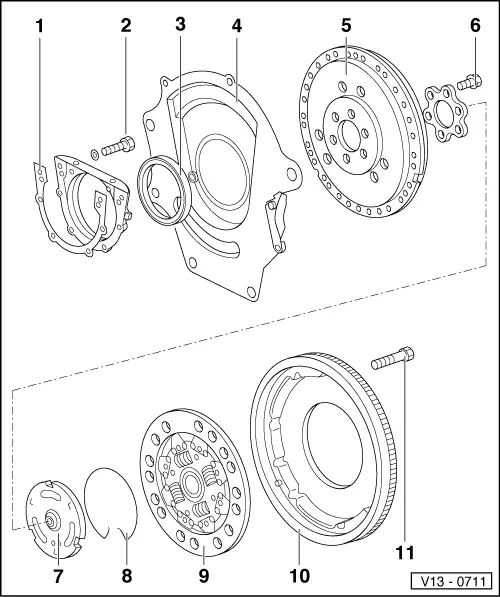

Dismantling and assembling cylinder block, crankshaft and flywheel

Dismantling and assembling cylinder block, crankshaft and flywheel

|

|

|

|

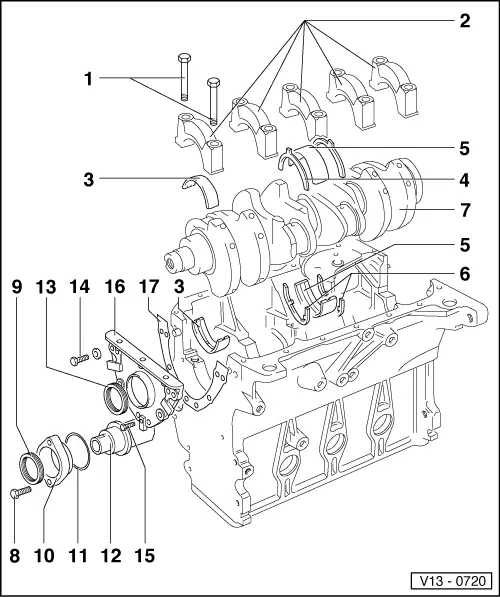

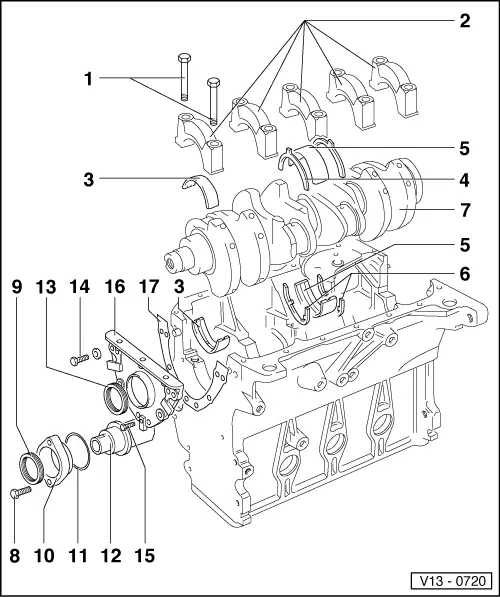

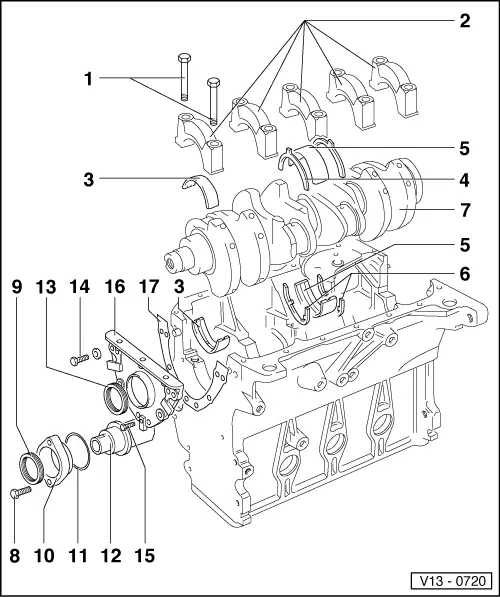

Dismantling and assembling cylinder block and crankshaft Note: Short engines are supplied with a needle bearing in the crankshaft. Before being installed in vehicles with automatic gearbox the needle bearing should be removed.

|

|

|

|

|

|

|

|

|

|

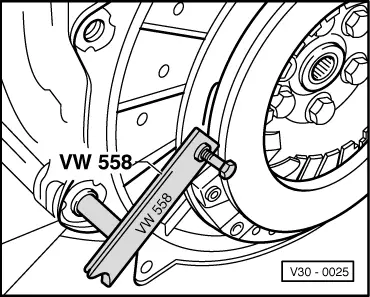

Removing and installing pressure plate and sealing flange Note: Clutch repairs

|

|

|

|

|

|

|

|

|

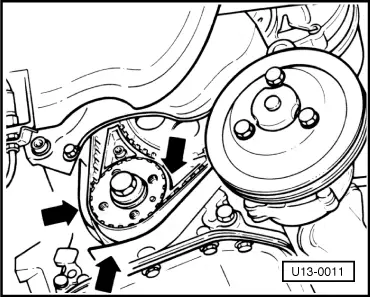

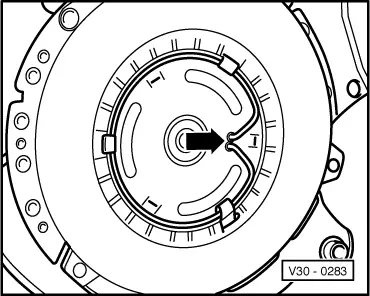

→ Fig.2 Removing and installing pressure plate |

|

|

|

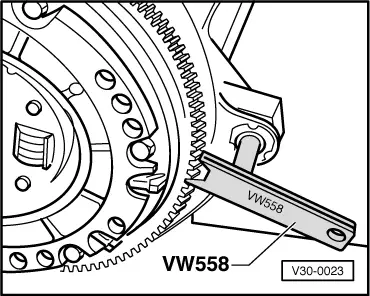

→ Fig.3 Removing and installing flywheel |

|

|

|

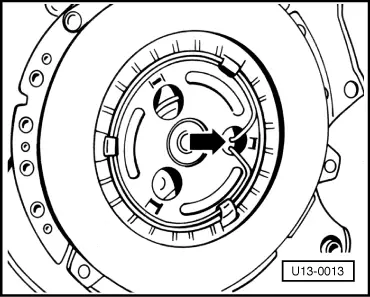

→ Fig.4 Installing retaining ring for the release plate, version A Pay attention to wire ends -arrow-. |

|

|

|

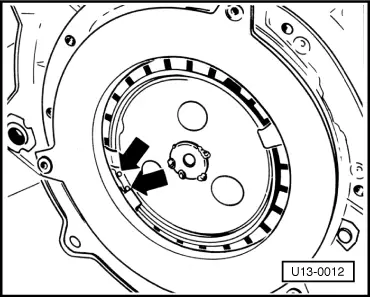

→ Fig.5 Installing retaining ring for the release plate, version B Pay attention to wire ends -arrows-. |

|

|

|

→ Fig.6 Installing retaining ring for the release plate, version C Pay attention to wire ends -arrow-. |