| –

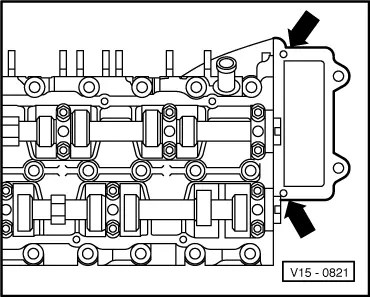

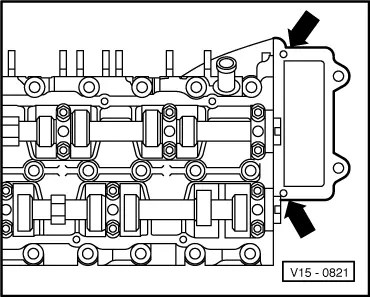

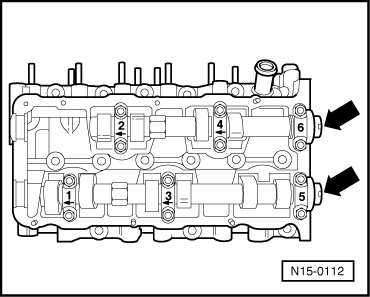

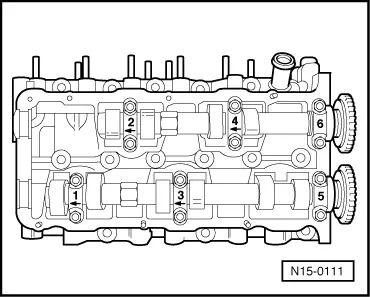

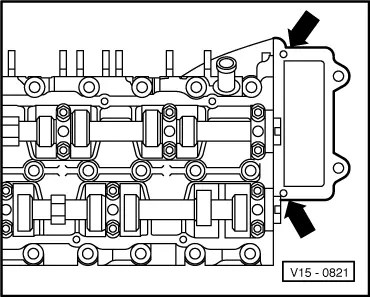

| Remove old sealant from 3 mm holes in cylinder head gasket -arrows-. |

Note | With the cylinder head installed, the holes in the cylinder head gasket are only half visible. |

| –

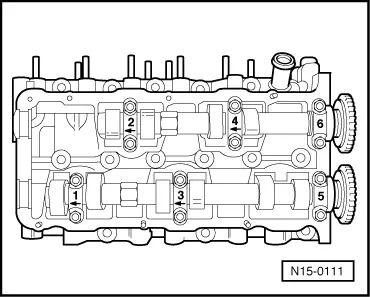

| Install camshaft chain sprockets with camshaft timing chain → Chapter. |

| –

| Fill 3 mm holes in cylinder head gasket with sealant AMV 188 001 02. |

| –

| Coat sealing surface of cover part with AMV 188 001 02. |

Note | Ensure that O-ring is installed for sealing oil channel in cover part. |

| –

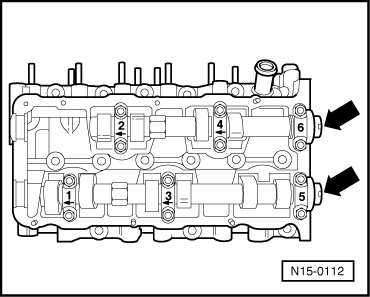

| Install cover, insert all securing bolts and tighten lightly. |

| –

| First tighten M8 securing bolts to 25 Nm and then tighten M6 securing bolts to 10 Nm. |

| –

| Install chain tensioner for camshaft timing chain and tighten to 40 Nm. |

Note | When new bucket tappets have been installed the engine must not be started for about 30 minutes. Hydraulic compensation elements must settle (otherwise valves will strike pistons). |

|

|

|

Note

Note

Note

Note Note

Note Note

Note

Note

Note

Note

Note Note

Note Note

Note