Golf Mk5

Note

Note

|

|

|

|

|

Note

Note

|

|

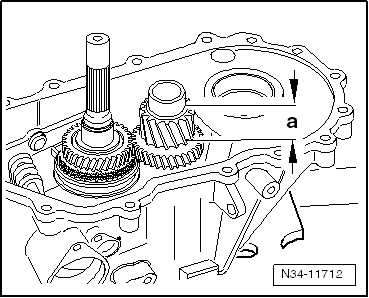

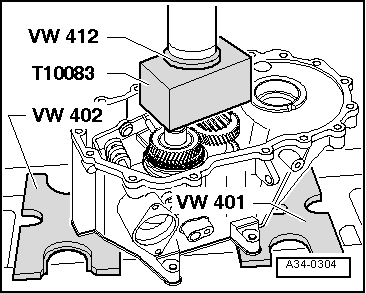

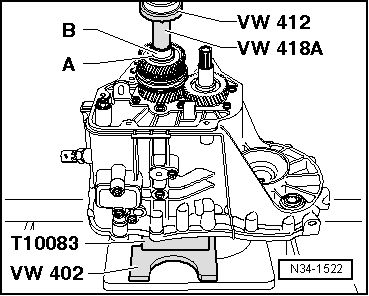

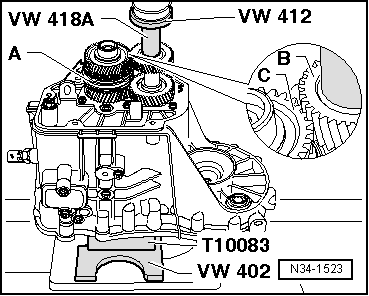

| Dimension -a- = 30.6 mm | |

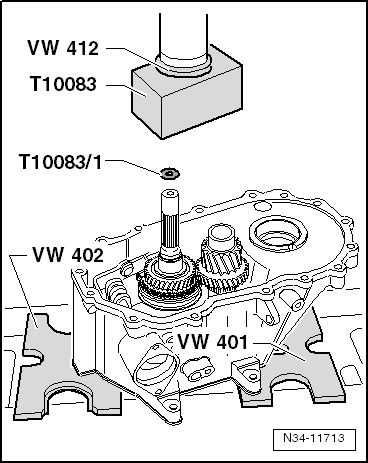

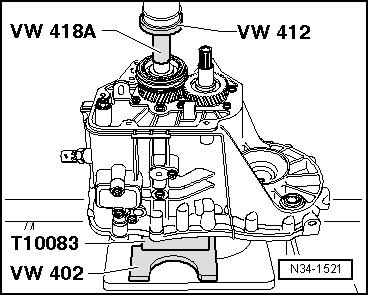

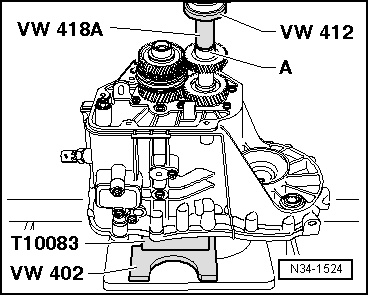

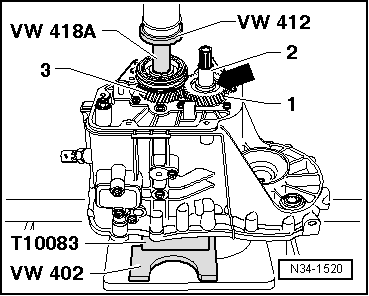

| Placing shim -T10083/1- onto input shaft → Fig. |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING