Golf Mk5

| Removing and installing sealing flange (belt pulley end) |

| Special tools and workshop equipment required |

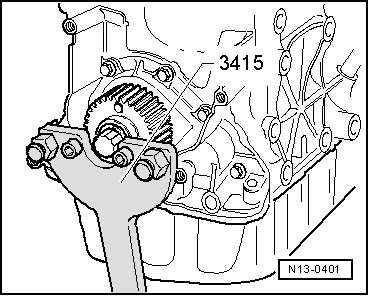

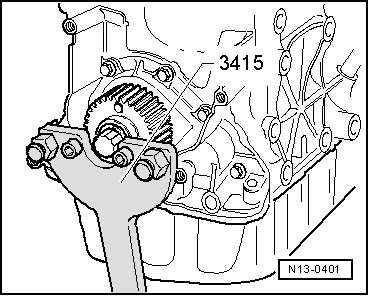

| t | Counterhold tool -3415- |

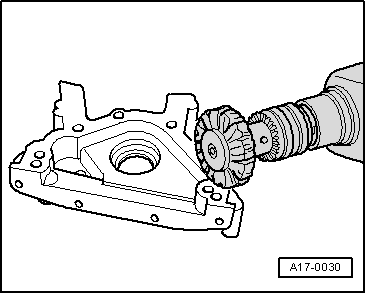

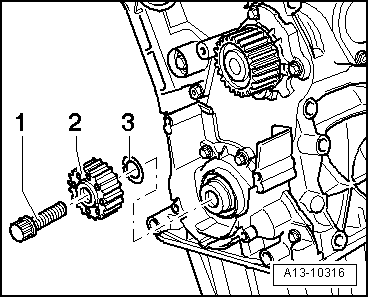

| t | Assembly tool -T10053- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Hand drill with plastic brush |

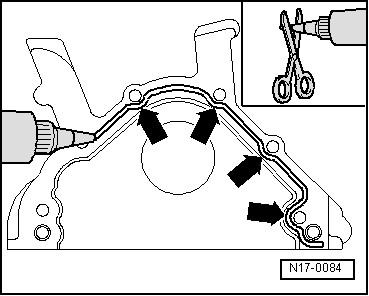

| t | Silicone sealant -D 176 404 A2- |

| t | Flat scraper |

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|