-

‒ →

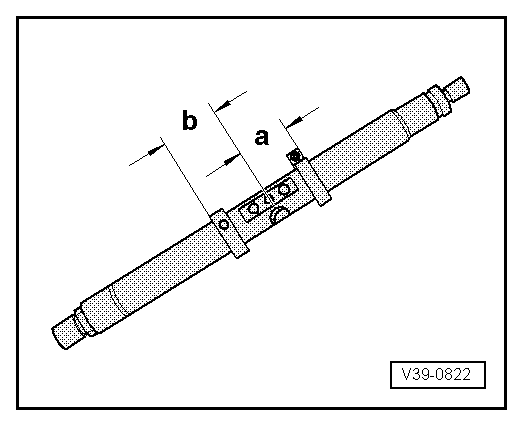

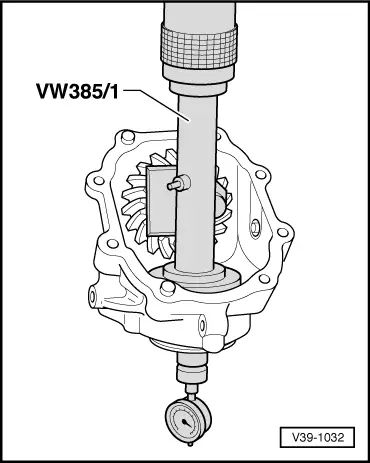

Measure dimension "e".

Turn mandrel until tip of dial gauge makes contact with end measuring plate and indicates max. deflection (return point). The measured value is dimension "e" (red number range). Example: 1.17 mm.

-

‒ Remove universal mandrel.

Note:

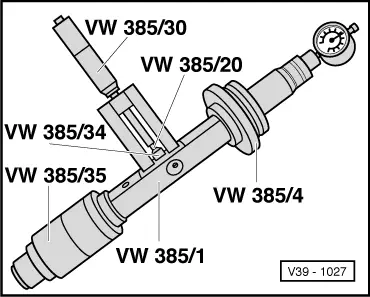

Finally, check again whether dial gauge with master gauge VW 385/30 in position and with 3 mm preload points to "0", otherwise repeat measurement.

Determining shim thickness "S3"

S3 = e - r

|

e

|

-

|

Determined value (max. deflection)

|

|

r

|

-

|

Deviation (on bevel gear given in 1/100 mm)

|

Example:

|

Measured dial gauge value "e"

|

1.17 mm

|

|

Deviation inscribed on bevel gear "r"

|

- 0.32 mm

|

|

Shim thickness "S3"

|

= 0.85 mm

|

The following adjustment shims are available:

|

|

|---|

|

Size (mm)

|

Part No.

|

|

0.15

0.30

0.35

0.40

0.50

|

009 409 247

009 409 247A

009 409 247B

009 409 247C

009 409 247D

|

-

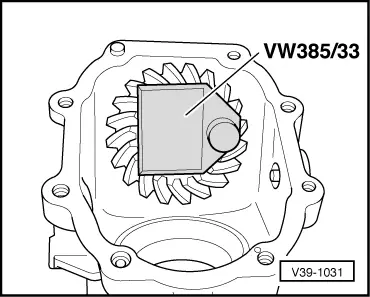

‒ Remove shaft bevel gear and install again with determined shim S3 and distance sleeve.

-

‒ Tighten hexagon nut as described on Page 39-132

.

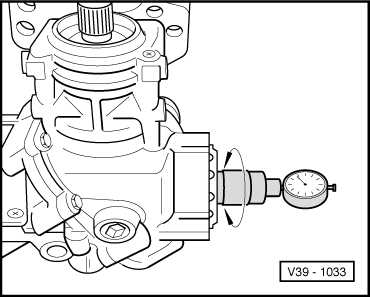

Checking dimension "r"

-

‒ Rotate shaft bevel gear several times in both directions.

-

‒ Insert universal mandrel and carry out check measurement.

If correct shims have been selected, the dial gauge reading anti-clockwise (red number range) must indicate the value of the inscribed deviation "r" on bevel gear with a tolerance of + 0.04 mm.

|