|

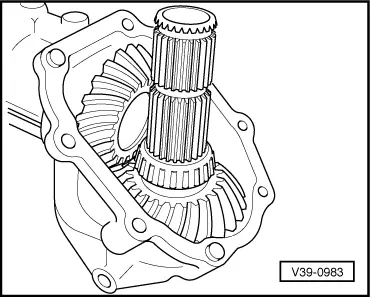

Shaft bevel gear with shim S3 installed.

Bevel gear with a 1.2 mm thick shim installed on the S2 side.

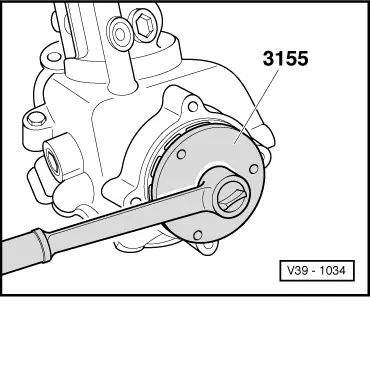

Total friction torque set.

-

‒ →

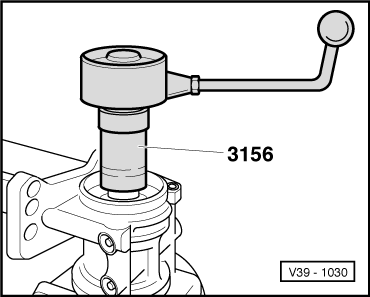

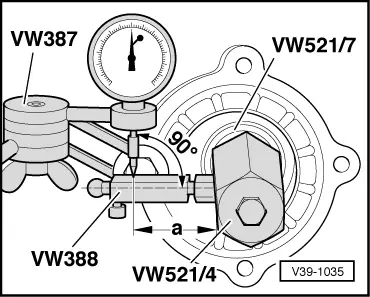

Assemble measuring tools.

-

‒ Dial gauge extension approx. 25 mm long.

-

‒ Dimension "a" = 39 mm.

-

‒ Screw measuring lever VW 388 in so that the dial gauge extension is at right angles to the measuring surface.

-

‒ Turn bevel gear on to stop. Set dial gauge to zero, turn bevel gear back and measure play. Note value.

-

‒ Loosen clamping sleeve locking screw and, after turning bevel gear through a further 90°repeat complete measuring process a further three times. Add the four measured values together and calculate average backlash.

Calculating average backlash

Example:

|

|

1st measurement

|

0.45 mm

|

|

|

+

|

2nd measurement

|

0.44 mm

|

|

|

+

|

3rd measurement

|

0.45 mm

|

|

|

+

|

4th measurement

|

0.46 mm

|

|

|

Total

|

1.80 mm

|

|

|

|

|

|

|

Average backlash = 1.80 mm /4

= 0.45 mm.

Note:

The relationship backlash to bevel gear with input shaft displacement is almost a ratio of 1:1. Therefore the calculated average backlash can be used directly for calculating S2.

Determining shim S2 thickness

|

S2

|

=

|

Inserted shim

|

|

|

-

|

average backlash

|

|

|

+

|

Lift (constant value)

|

Lift = 0.20 mm

|

Example:

|

|

|

|

Fitted shim

|

1.20 mm

|

|

-

|

average backlash

|

0.45 mm

|

|

|

|

0.75 mm

|

|

+

|

Lift (constant)

|

0.20 mm

|

|

S2

|

=

|

0.95 mm

|

The following adjustment shims are available:

|

|

|---|

|

Size (mm)

|

Part No.

|

|

0.15

0.20

0.30

|

113 517 201A

113 517 202A

113 517 203A

|

|

0.40

0.50

0.60

|

113 517 204A

113 517 205A

113 517 206A

|

|

0.70

0.80

0.90

|

113 517 207A

113 517 208A

113 517 209A

|

|

1.00

1.20

|

113 517 210A

113 517 211A

|

-

‒ Remove rear axle housing, remove bearing support and press taper roller bearing outer race out. Remove 1.2 mm shim.

-

‒ Insert determined S2 and reinstall outer race.

Carrying out check measurement

-

‒ Install rear axle housing with installed bearing support to bevel gear housing.

-

‒ Tighten ring nut until the total friction torque is set.

-

‒ Measure backlash, it must be between

0.15 - 0.25 mm.

-

‒ Mark position of ring nut to housing.

After installing components and after installing rear axle housing to bevel gear housing tighten ring nut to the position marked during control measurement.

|