Passat (B3)

|

|

|

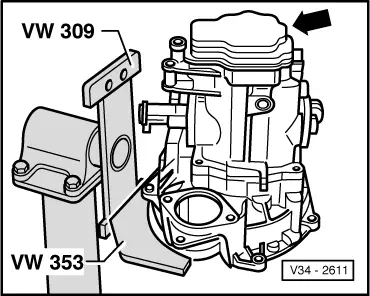

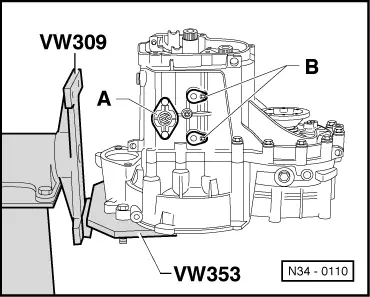

Remove bevel box as follows:

|

|

|

|

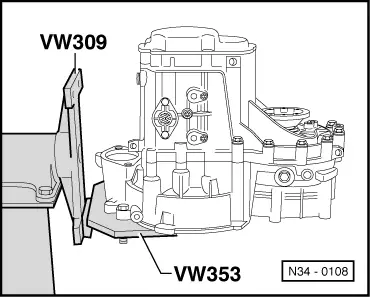

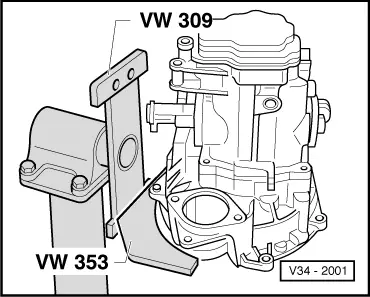

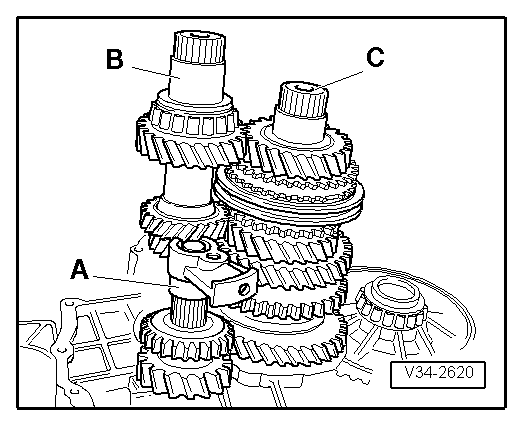

On vehicles with 6 cylinder injection engine:

On vehicles with 4 cylinder engine: |

|

|

|

|

|

|

|

|

Note: Before lifting the locking collar, take off spring and lock body. Then afterwards replace locking collar on syncro-hub again, but without selector fork. |

|

|

|

|

|

|

|

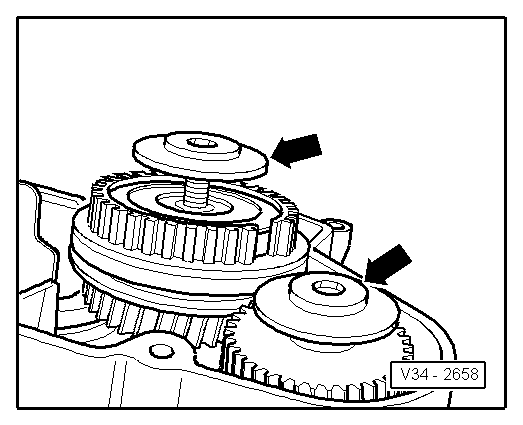

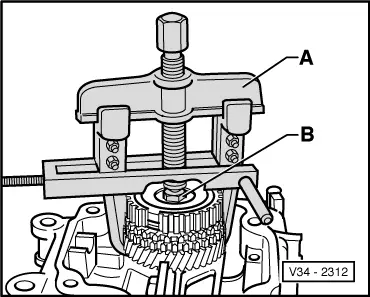

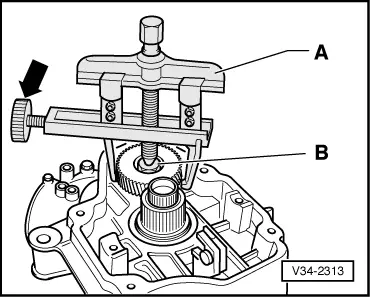

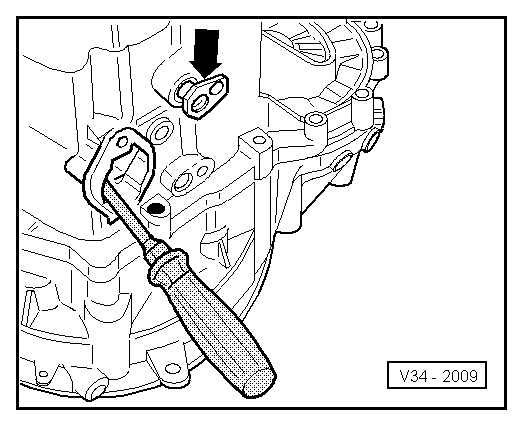

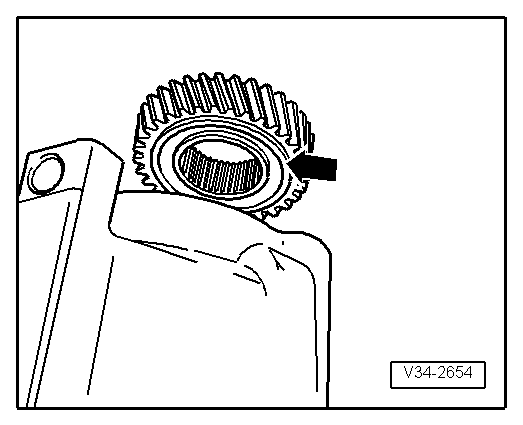

Note: When pulling off the gear wheel ensure that the hooks do not bend outwards, if necessary tighten screw (arrow). Check 5th gear wheel for damage after removal. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

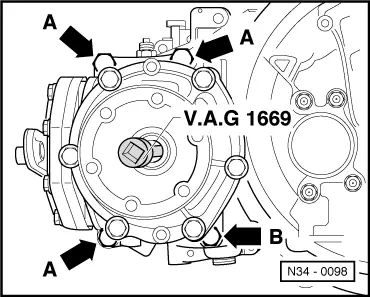

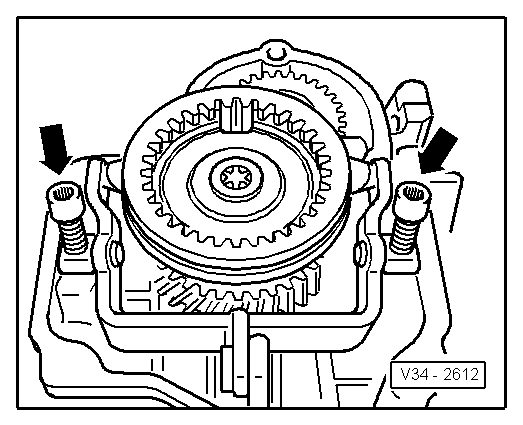

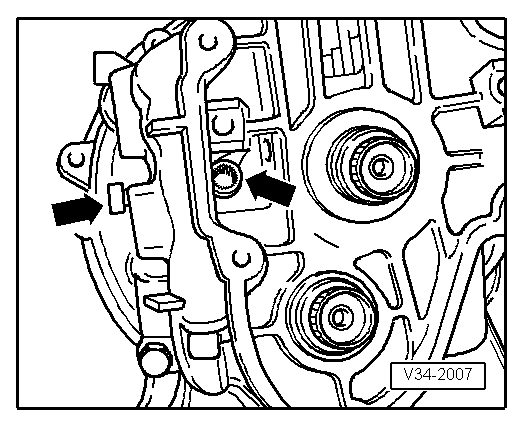

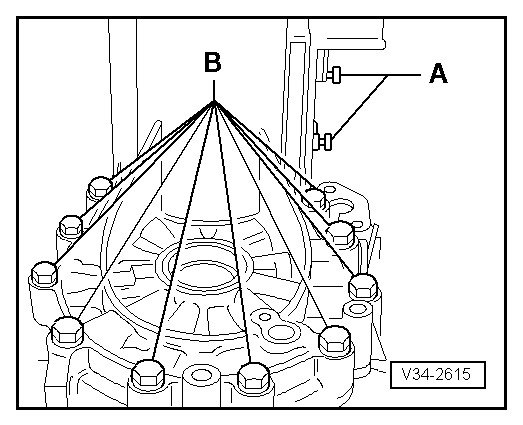

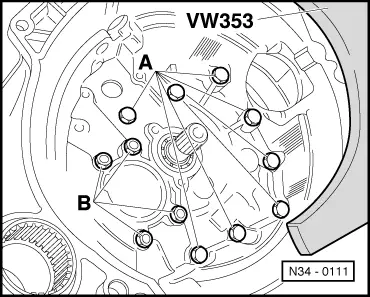

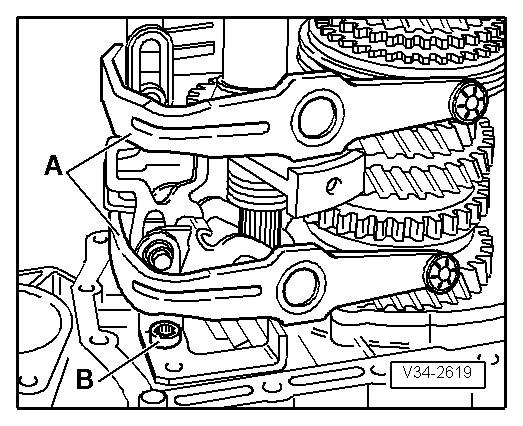

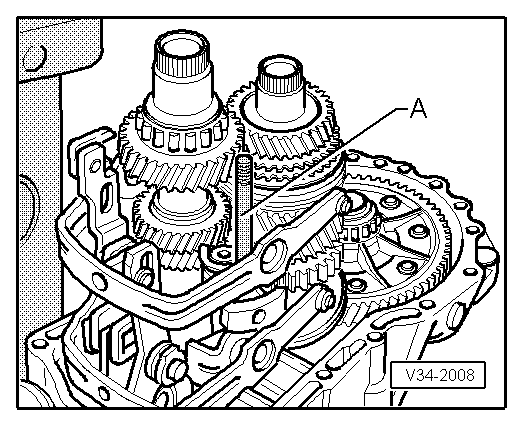

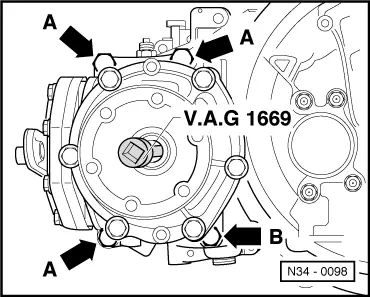

Note: Do not remove nuts -B- for output shaft bearing support. |

|

|

|

|

|

|

|

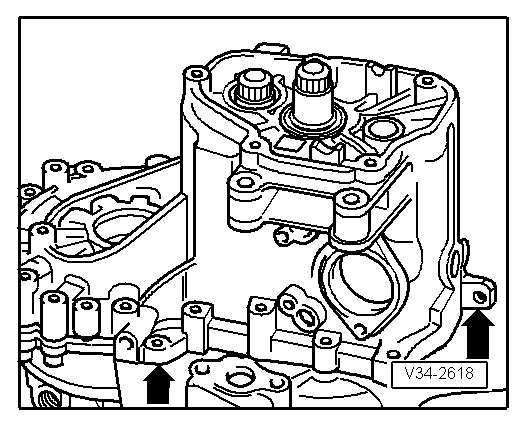

Assembling

|

|

|

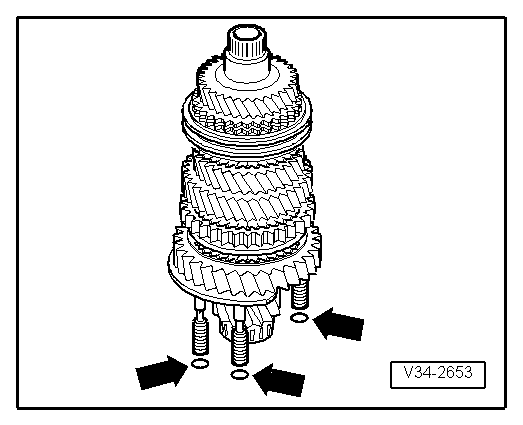

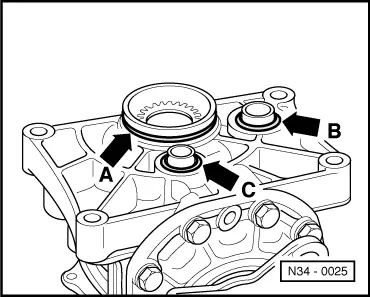

Note: The illustration only shows 3 of the 4 sealing rings.

|

|

|

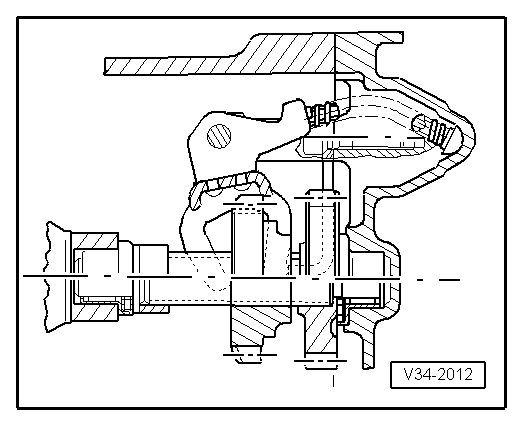

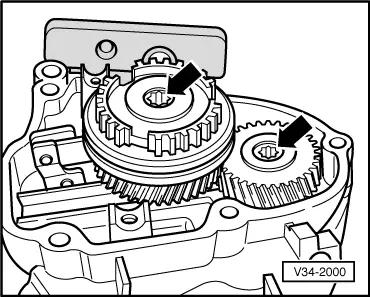

→ Installation position reverse gear

|

|

|

Note: The selector segments must be positioned in the grooves on the locking collars.

|

|

|

|

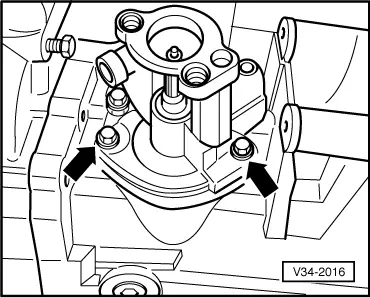

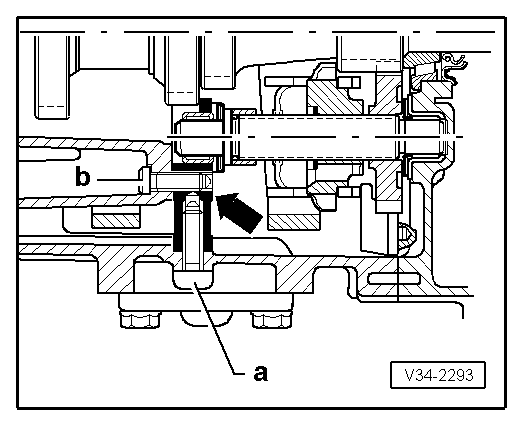

Install reverse shaft support bolts (arrow) as follows:

|

|

|

|

|

|

|

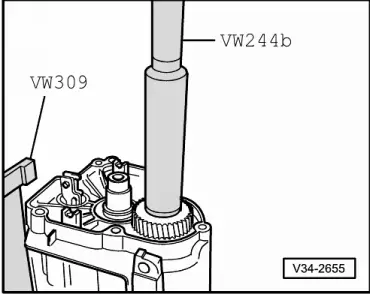

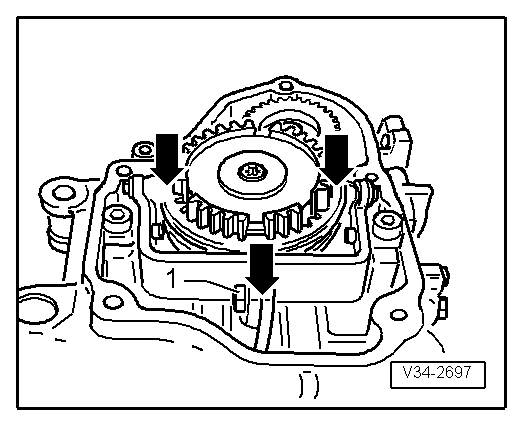

→ Install selector shaft as follows:

|

|

|

|

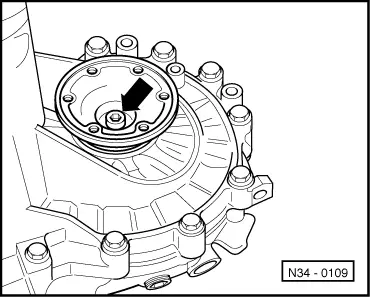

→ Installation position 5th gear wheel The circumferential groove (arrow) faces to gearbox housing. |

|

|

|

|

|||||||

|

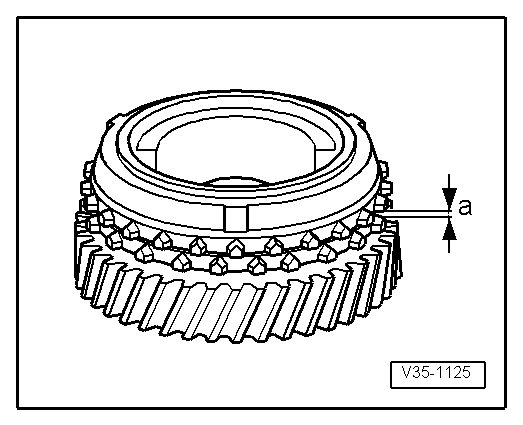

Checking 5th gear synchro-ring

|

|

|

|

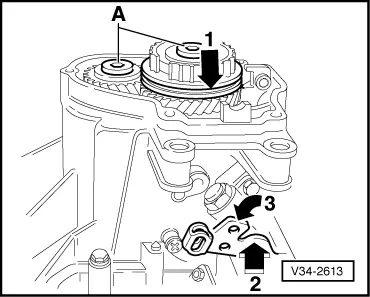

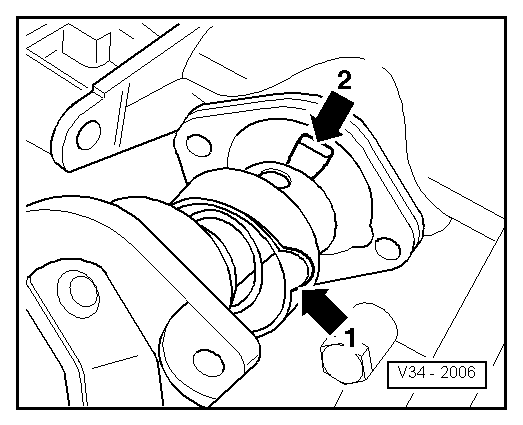

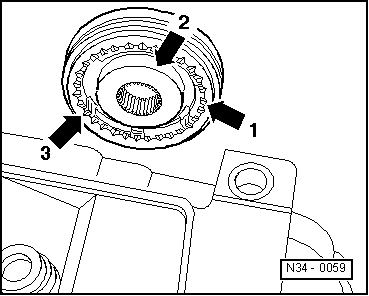

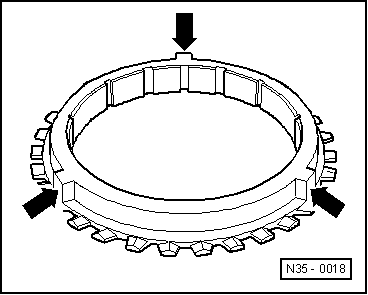

→ Installation position 5th gear synchro-hub/locking collar The pointed teeth of the locking collar (arrow 1) and the high shoulder of the synchro-hub (arrow 2) face the gearbox housing. The syncro-hub mountings (arrow 3) align with the synchro-ring cast locking pieces (=>arrows on Illustration N35-0018, Page 34-104 ). |

|

|

|

→ 5th gear synchro-ring with cast locking pieces (arrows) |

|

|

|

Note: When driving on ensure synchro-ring is free to move. |

|

|

|

|

|

|

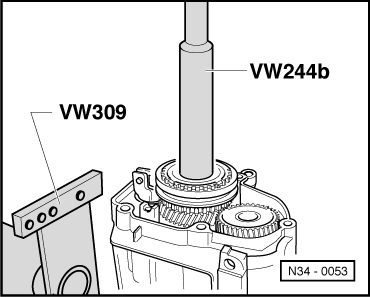

→ Adjusting 5th gear:

On vehicles with 6 cylinder injection engine: |

|

|

|

Build bevel box on as follows:

|

|

|

|