Passat (B3)

|

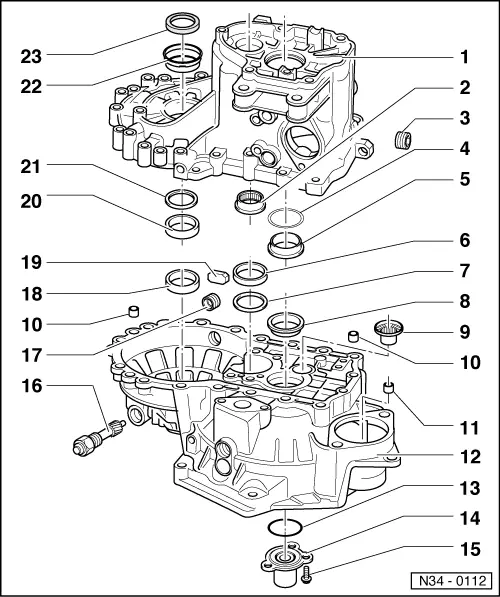

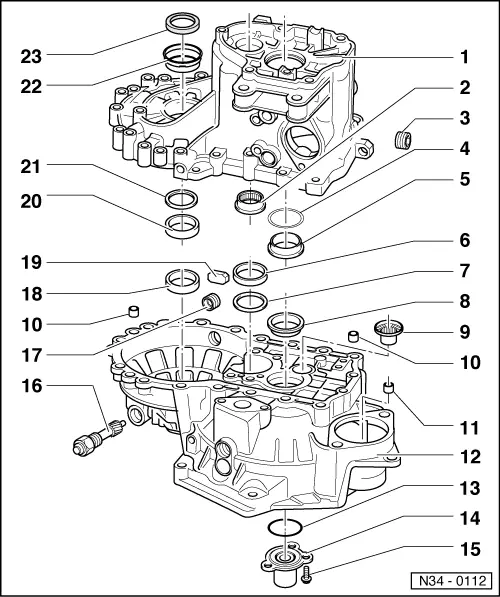

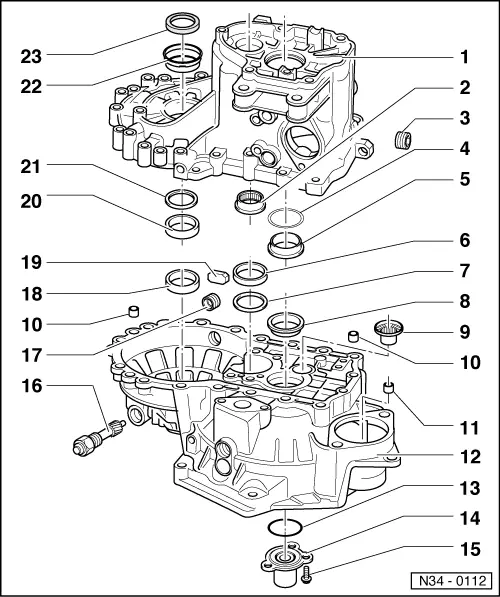

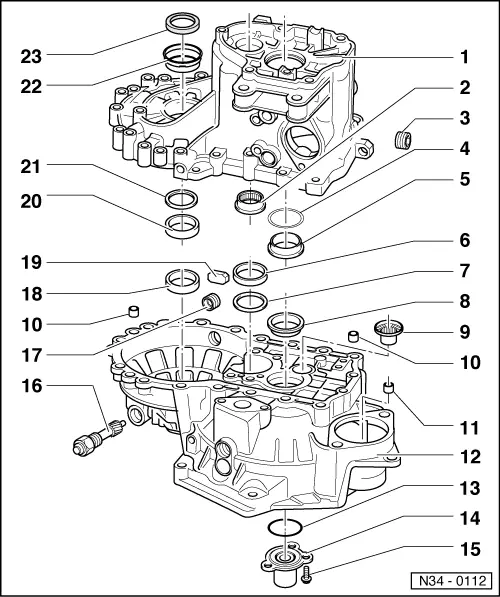

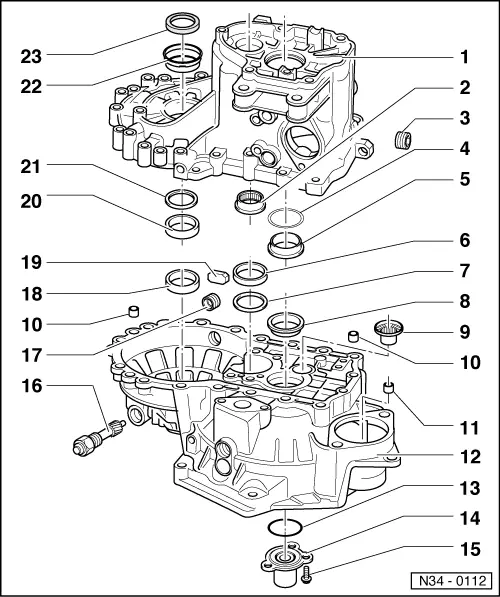

Servicing gearbox housing and clutch housing

Servicing gearbox housing and clutch housing

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

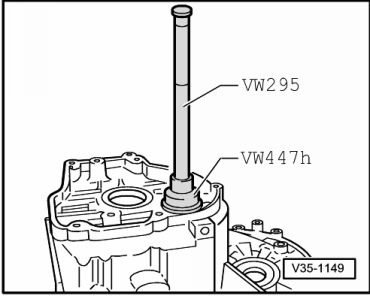

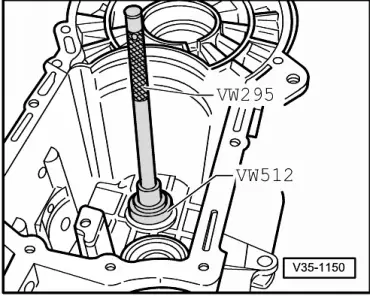

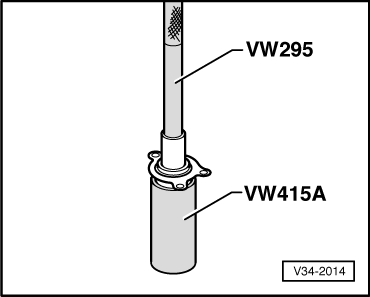

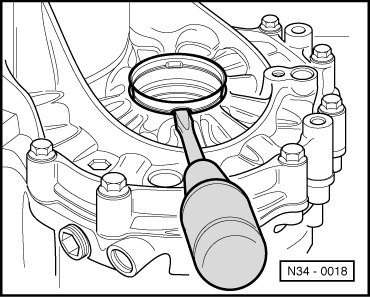

→ Fig.1 Driving out needle roller bearing |

|

|

|

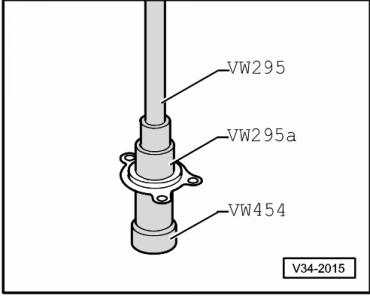

→ Fig.2 Knocking needle roller bearing in onto stop |

|

|

|

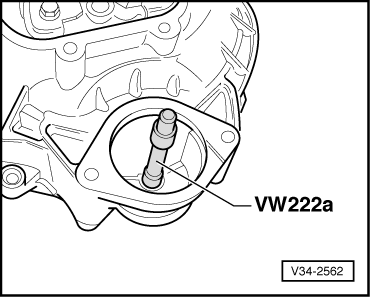

→ Fig.3 Driving oil seal out of guide sleeve. |

|

|

|

→ Fig.4 Driving oil seal into the guide sleeve onto stop. |

|

|

|

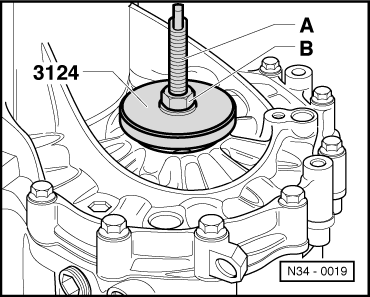

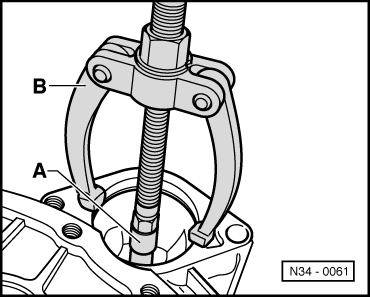

→ Fig.5 Pulling out starter bush. A - Internal extractor, e.g. Kukko 21/2, 14.5 ... 18.5 mm B - Counter support. e.g. Kukko 22/1 |

|

|

|

→ Fig.6 Driving in starter bush. |

|

|

|

→ Fig.7 Lever out sleeve with screwdriver |