|

→

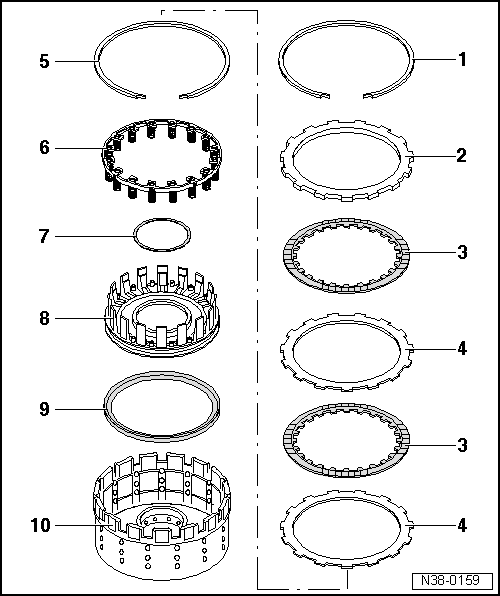

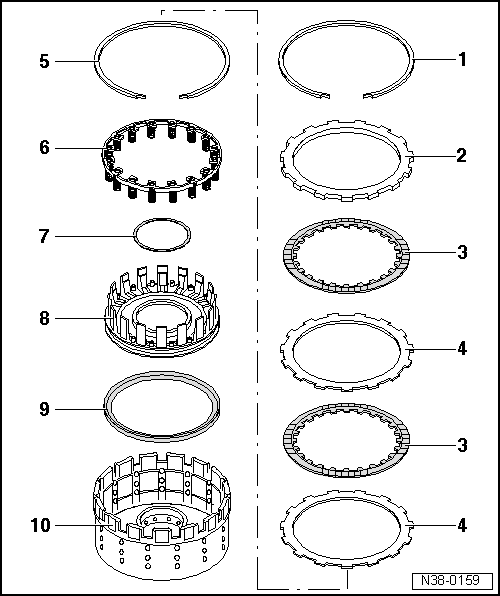

Fig.4

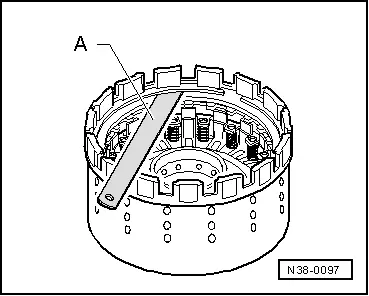

Functional check of clutch

-

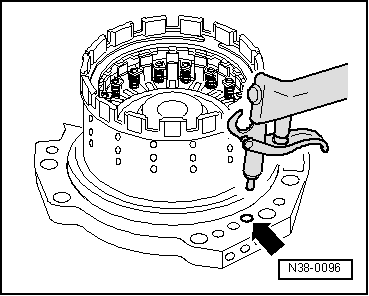

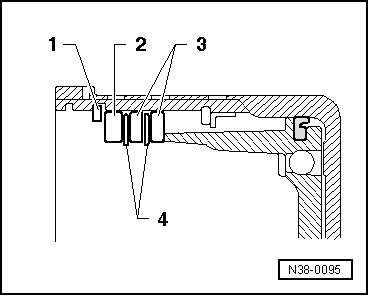

‒ Before installing the piston moisten the sealing lips and sealing rings with ATF.

Sealing lip faces to clutch housing.

-

‒ Turn piston slightly when installing.

-

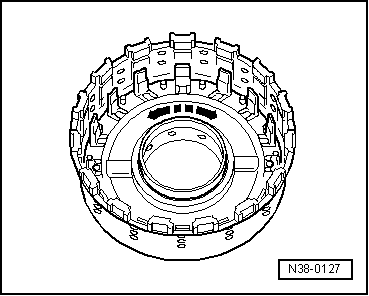

‒ It must be possible to turn the piston by hand in both directions (arrows) after it has been installed into clutches or brakes.

-

◆ If this is not the case, the sealing lips or sealing rings may catch or become damaged.

-

‒ If this defect occurs, remove piston again.

-

‒ Check sealing lips or sealing rings for damage, renew if necessary.

-

‒ Install piston again and check.

|