Polo Mk4

|

Note

Note

|

|

| Admissible deviation from the nominal value | Possible cause of the fault | Troubleshooting | ||||||||||||||||||||

|

|

| ||||||||||||||||||||

| ||||||||||||||||||||||

|

|

| ||||||||||||||||||||

|

|

Note

Note| t | If no fault is found, vent the refrigerant gas loop → Chapter. |

| t | Check measurement values for the Air outlet temperature sensor for the evaporator -G263- and operation of the Adjustment valve for the air conditioning compressor -N280-. If the measurement value for the High pressure sensor -G65- is incorrect, the evaporator may freeze or the cooling power is not be reached. |

| t | If the air conditioning continues to malfunction, after repeating the check, replace the expansion valve again and vent the refrigerant gas loop. Then, replace the compressor and the liquid tank/dryer filter. |

| t | In this type of fault, the evaporator may freeze even though there is an adequate amount of refrigerant gas in the refrigerant gas loop. |

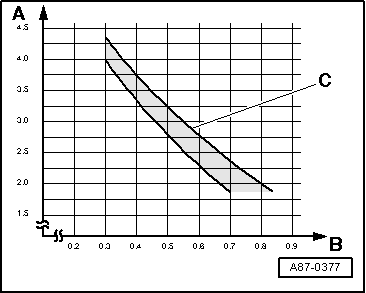

| t | If the expansion valve is faulty (permanently closed or only partly open), the Adjustment valve for the air conditioning compressor -N280- is adjusted for maximum power and the low pressure decreases to the value given in the diagram or below it (the air conditioning compressor sucks the refrigerant gas from the low pressure side). Since the refrigerant gas cannot pass through the expansion valve, the cooling power is not reached and the high pressure may not rise or rise only marginally, as there is no energy transformation. |

| Admissible deviation from the nominal value | Possible cause of the fault | Troubleshooting | ||||||||||||||||||||

|

|

| ||||||||||||||||||||

|

| |||||||||||||||||||||

|

|

| ||||||||||||||||||||

|

| |||||||||||||||||||||

|

|

Note

Note| t | In this type of fault, the evaporator may freeze even though there is an adequate amount of refrigerant gas in the refrigerant gas loop. |

| t | If the expansion valve is damaged (permanently closed or only partly open), the Adjustment valve for the air conditioning compressor -N280- is adjusted for maximum power and the low pressure decreases to the value given in the diagram or below (the air conditioning compressor sucks the refrigerant gas from the low pressure side). Since the refrigerant gas cannot pass through the expansion valve, the cooling power is not reached and the high pressure may not rise or rise only marginally, as there is no energy transformation. |

| Admissible deviation from the nominal value | Possible cause of the fault | Troubleshooting | ||||||||||||||||||||||||

|

|

| ||||||||||||||||||||||||

|

|

|

Note

Note

|

| Admissible deviation from the nominal value | Possible cause of the fault | Troubleshooting | ||||||||||||

|

|

| ||||||||||||

|

| |||||||||||||

|

|

Note

Note

|

| Admissible deviation from the nominal value | Possible cause of the fault | Troubleshooting | ||||||||||||||||||||||||||

|

|

| ||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||

|

|

Note

Note| t | If the fault is located in the Adjustment valve for the air conditioning compressor -N280- (the adjustment valve does not operate but the compressor continues to run), it is not necessary to vent the refrigerant gas loop. In this type of fault only the air conditioning compressor needs to be replaced (correct the amount of refrigerant gas oil in the new air conditioning compressor). |

| t | If the expansion valve is faulty (permanently closed or only partly open), the Adjustment valve for the air conditioning compressor -N280- is adjusted for maximum power and the low pressure decreases to the value given in the diagram or below it (the air conditioning compressor sucks the refrigerant gas from the low pressure side). Since the refrigerant gas cannot pass through the expansion valve, the cooling power is not reached and the high pressure may not rise or rise only marginally, as there is no energy transformation. |

| Admissible deviation from the nominal value | Possible cause of the fault | Troubleshooting | ||||||||||||||

|

|

| ||||||||||||||

|

|

| ||||||||||||||

|

|

Note

Note| t | Excessive filling of refrigerant gas oil may occur, for example, when the compressor is replaced without correcting the amount of refrigerant gas oil. |

| t | If the expansion valve is damaged (always open), the temperature in the evaporator is not regulated in order to ensure that the refrigerant gas comes out of the evaporator in gaseous form. Under certain operating conditions, the compressor may suck in liquid drops, causing noise (liquid cannot be condensed). |