A2

| Exploded view - servicing gearbox housing and clutch housing |

| Special tools and workshop equipment required |

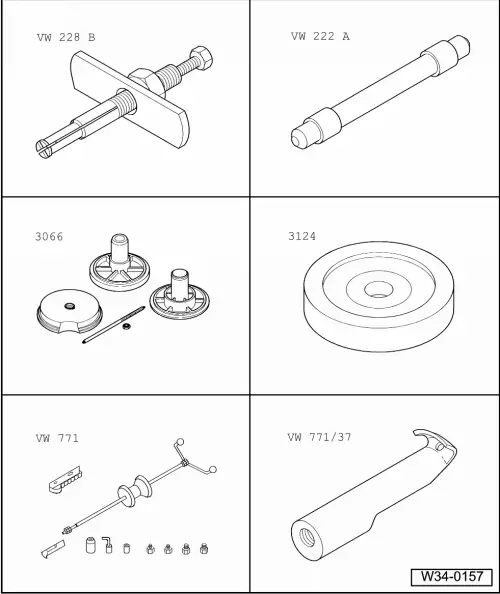

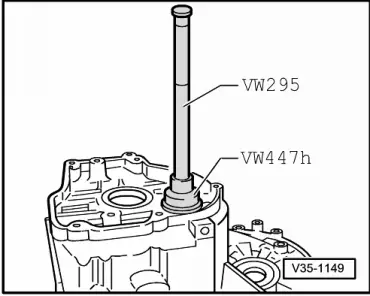

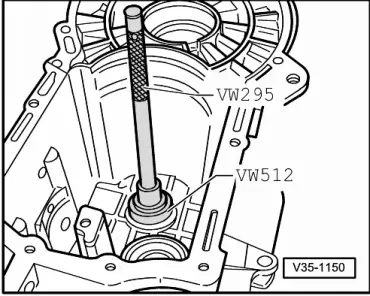

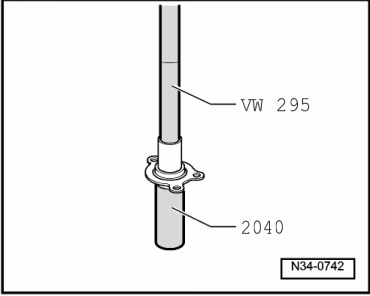

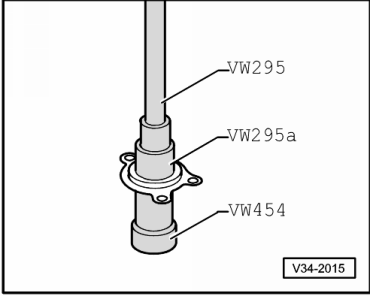

| t | Drift -VW 295- |

| t | Adapter -VW 295 A- |

| t | Thrust plate -VW 447 H- |

| t | Thrust pad -VW 512- |

| t | Press tool -VW 454- |

| t | Tube -2040- |

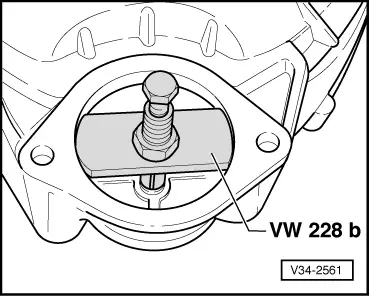

| t | Extractor -VW 228 B- |

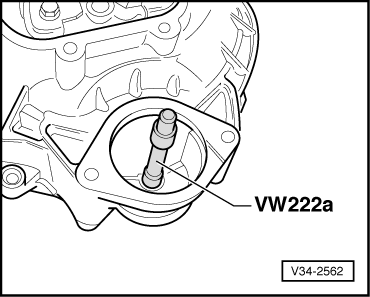

| t | Drift -VW 222 A- |

| t | Spindle from assembly device -3066- |

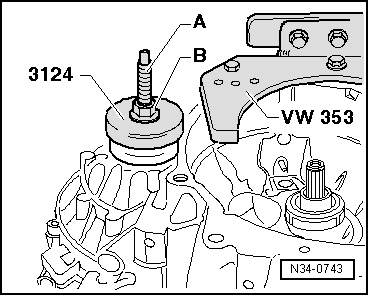

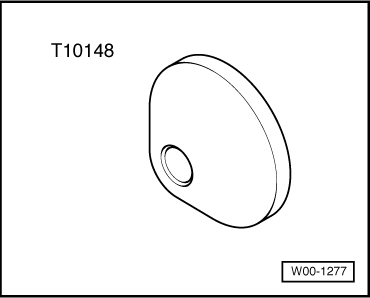

| t | Thrust piece -3124- (for two-piece oil seal and sleeve) |

| t | Multi-purpose tool -VW 771- (for one-piece oil seal and sleeve) |

| t | Puller hook -VW 771/37- (for one-piece oil seal and sleeve) |

|

|

|

|

| 1 - | Gearbox housing |

| q | If renewed: Adjust input shaft and differential → Chapter |

| 2 - | Needle bearing |

| q | For output shaft |

| q | Removing → Fig. |

| q | Installing and securing → Fig. |

| 3 - | Oil filler plug |

| q | 30 Nm |

| 4 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Removing and installing → Fig. |

| q | If renewed: Adjust input shaft → Chapter |

| 5 - | Shim |

| q | For output shaft |

| q | Table of adjustments → Chapter |

| 6 - | Shim |

| q | For input shaft |

| q | Table of adjustments → Chapter |

| 7 - | Tapered roller bearing outer race |

| q | For output shaft |

| q | Removing and installing → Fig. |

| q | If renewed: Adjust output shaft → Chapter |

| 8 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Removing and installing → Fig. |

| q | If renewed: Adjust input shaft → Chapter |

| 9 - | Needle bearing |

| q | Removing and installing → Fig. |

| 10 - | Dowel sleeve |

| q | 2x |

| 11 - | Starter bush |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| q | Can be renewed with gearbox in vehicle |

| 12 - | Clutch housing |

| q | If replaced: → Chapter |

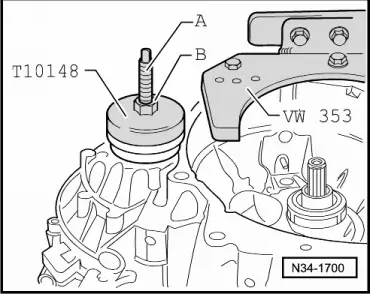

| 13 - | Guide sleeve |

| q | With input shaft oil seal and vulcanised O-ring |

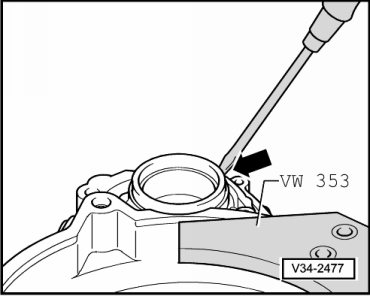

| q | Driving out oil seal → Fig. |

| q | Driving in oil seal → Fig. |

| q | Remove guide sleeve in order to renew oil seal |

| q | If O-ring is damaged, renew both guide sleeve and O-ring |

| 14 - | Bolt |

| q | 20 Nm |

| 15 - | Oil seal |

| q | For flange shaft (right-side) |

| q | Renewing → Chapter |

| 16 - | Sleeve |

| q | For oil seal (right-side) → Item |

| q | Removing → Fig. |

| q | Installing → Fig. |

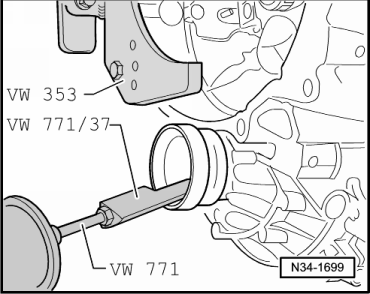

| 17 - | One-piece oil seal and sleeve |

| q | If oil seal is damaged, renew both sleeve and oil seal |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 18 - | Speedometer drive |

| q | Tighten aluminium version to 30 Nm |

| q | Tighten plastic version to 10 Nm |

| 19 - | Oil drain plug |

| q | 30 Nm |

| 20 - | Tapered roller bearing outer race |

| q | For differential |

| q | Removing and installing → Chapter |

| q | If renewed: adjust differential → Chapter |

| 21 - | Magnet |

| q | Held in place by joint surface of housing |

| 22 - | Tapered roller bearing outer race |

| q | For differential |

| q | Removing and installing → Chapter |

| q | If renewed: adjust differential → Chapter |

| 23 - | Shim |

| q | For differential |

| q | Table of adjustments → Chapter |

| 24 - | Oil seal |

| q | For flange shaft (left-side) |

| q | Renewing → Chapter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|