| –

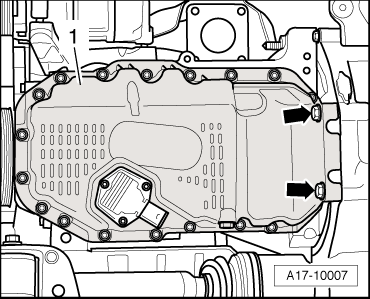

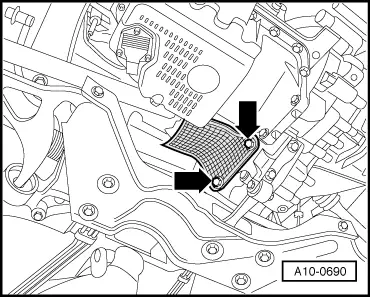

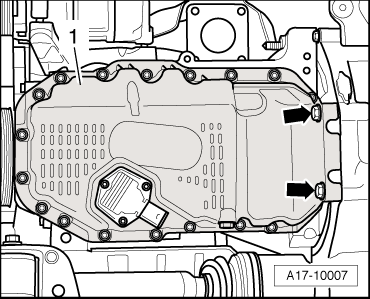

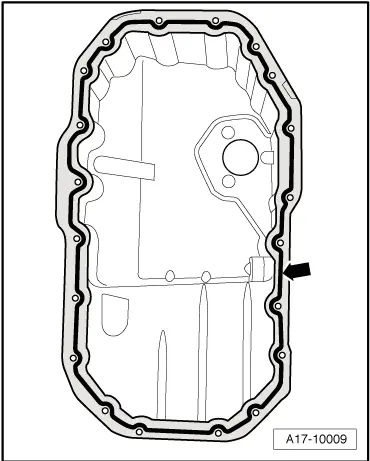

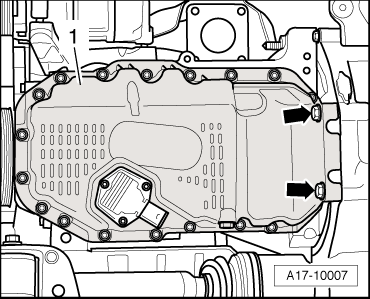

| Fit sump and tighten bolts → Fig.. |

Note | t

| If sump is fitted with engine removed, make sure sump is flush with cylinder block at gearbox end. |

| t

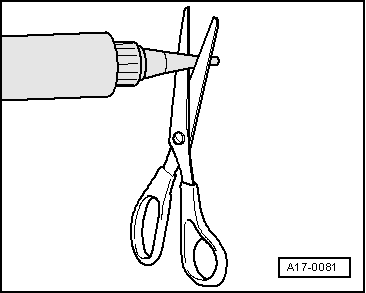

| After fitting sump assembly, the sealant must dry for approx. 30 minutes. Then (and only then) fill the engine with engine oil. |

| Remaining installation steps are carried out in reverse sequence; note the following: |

| –

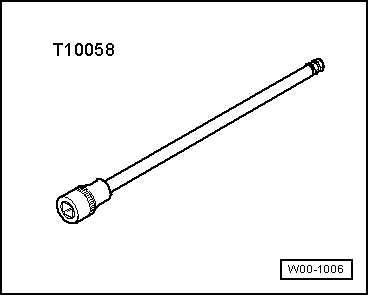

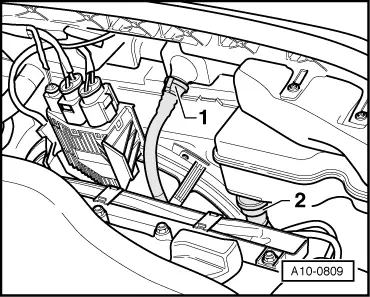

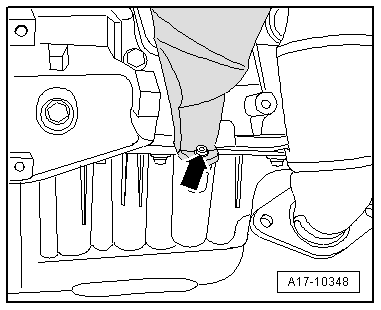

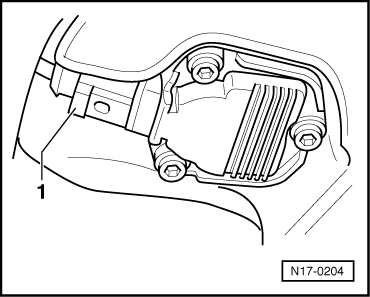

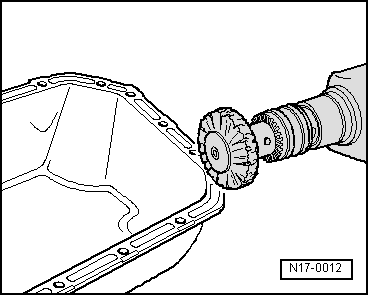

| Install connection with guide tube for oil dipstick and oil filler pipe → Fig.. |

| –

| Install front exhaust pipe with catalytic converter → Chapter. |

| –

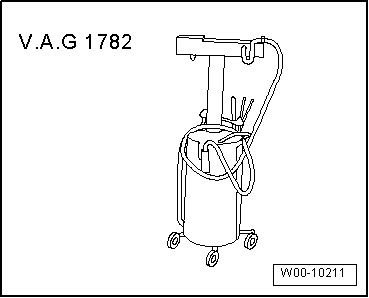

| Fill up with engine oil and check engine oil level → Booklet809. |

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING