| –

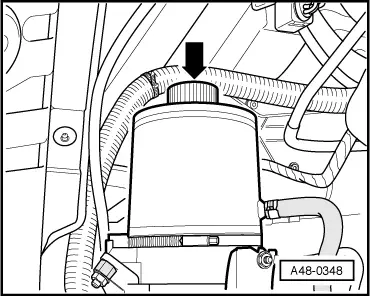

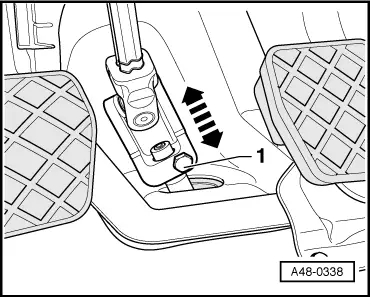

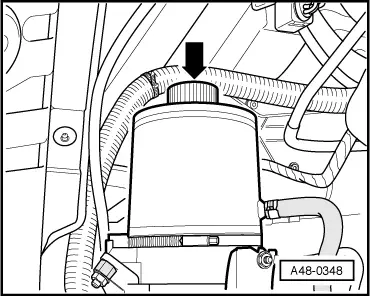

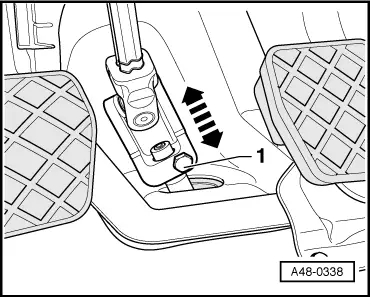

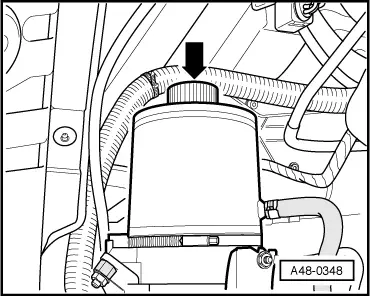

| Remove screw cap -arrow- from fluid reservoir of motor/pump unit. |

| –

| Extract hydraulic fluid via the filler neck with a commercially available extractor bottle. |

Note! | t

| Small quantities of hydraulic fluid will remain in the motor/pump unit as well as in the return line and expansion hose after extraction. |

| t

| Do not re-use hydraulic fluid which has been drained off. |

| t

| The expansion hose and return line must not be clamped with hose clamps, e.g. -3094- or other tools. Clamping can cause damage to the expansion hose and return line. |

| t

| To avoid damage, a bending radius of less than 100 mm is not permissible when bending or suspending the expansion hose and return line. |

| –

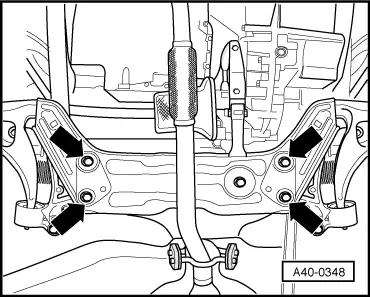

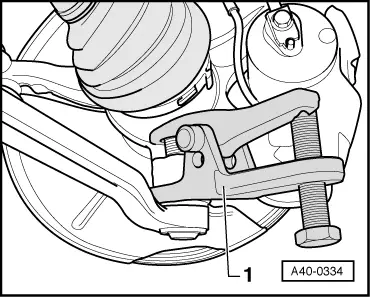

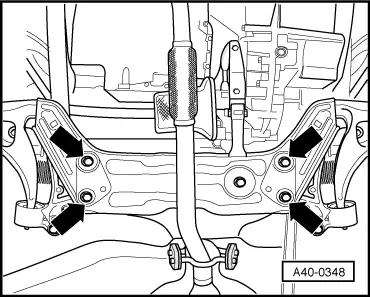

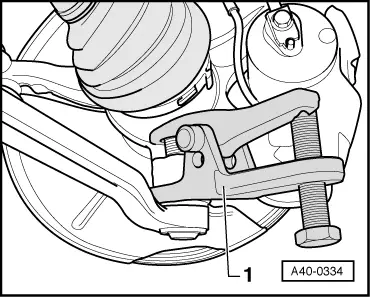

| Place drip tray under steering box to collect escaping hydraulic fluid. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!