A3 Mk1

Note

Note

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

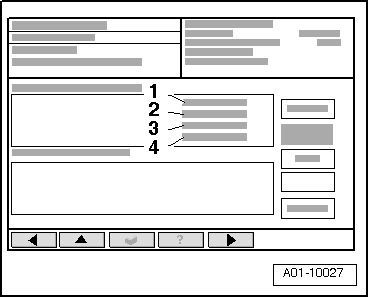

| System pressure at idling speed | ||

| Selector lever position | “D” | “R” |

| Engine speed | Idling | Idling |

| System pressure in bar | 3.4 … 3.8 | 5.0 … 6.0 |

|

|

|

| System pressure at 2000 rpm | ||

| Selector lever position | “D” | “R” |

| Engine speed | 2000 rpm | 2000 rpm |

| System pressure in bar | 12.4 … 13.2 | 23.0 … 24.0 |

|

| Component | Nm |

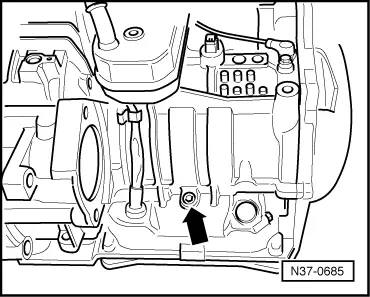

| Bolt for system pressure hole | 15 |

Note

Note

Note

Note

|