A3 Mk2

|

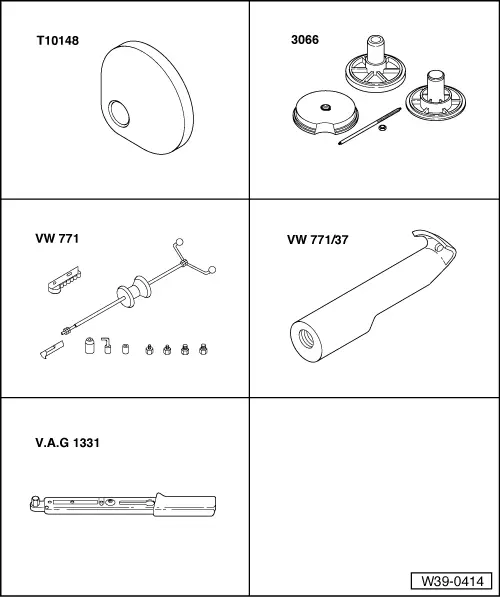

| Special tools and workshop equipment required |

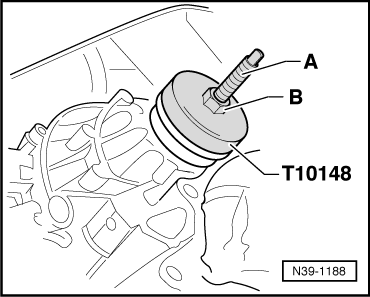

| t | Thrust piece -T10148- |

| t | Spindle from assembly device -3066- |

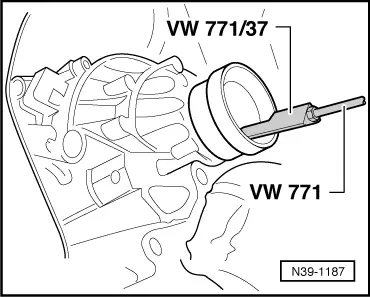

| t | Multi-purpose tool -VW 771- |

| t | Puller hook -VW 771/37- |

| t | Torque wrench -V.A.G 1331- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

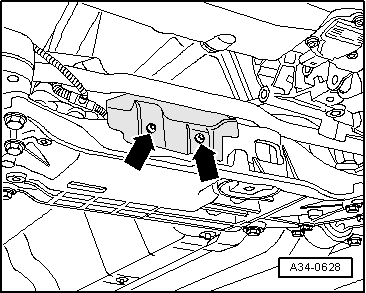

| Component | Nm | |

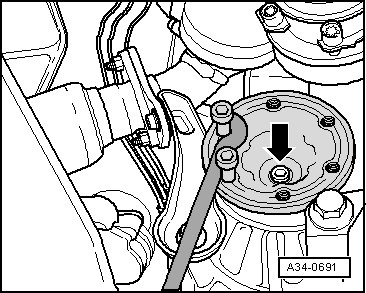

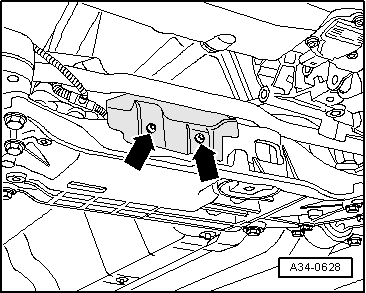

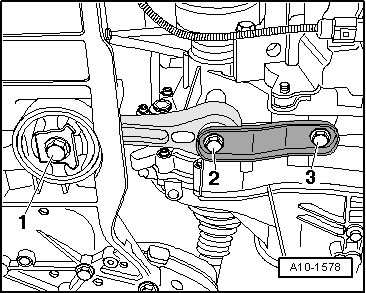

| Heat shield for drive shaft to cylinder block, M10 | 40 | |