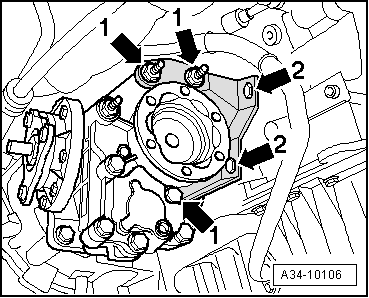

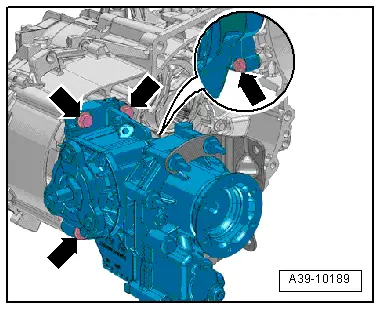

| Installation is carried out in reverse sequence; note the following: |

| t

| Renew gaskets, seals and self-locking nuts. |

| –

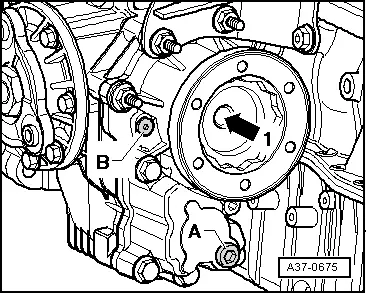

| Push bevel box fully onto gearbox, ensuring that splines of bevel box input shaft and differential are centred when brought together. |

| –

| Also align the teeth of the flange shaft (right-side) and the differential pinion; if necessary turn the flange shaft. |

| –

| If the teeth are correctly positioned and the components are located centrally, the bevel box will slide against the gearbox onto the stop. |

|

|

|

Note

Note

Note

Note