A3 Mk2

| Dismantling and assembling input shaft |

| Special tools and workshop equipment required |

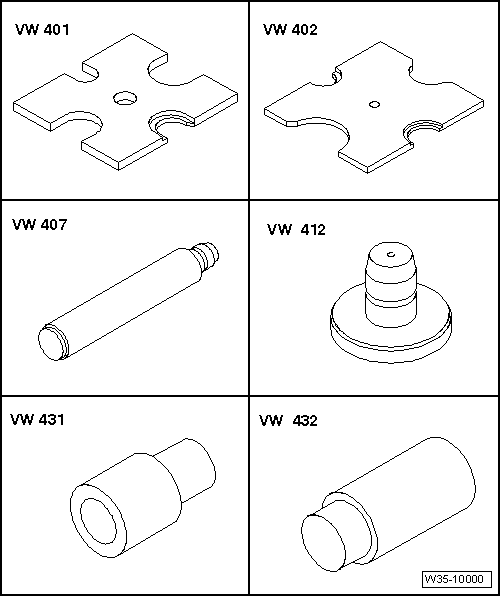

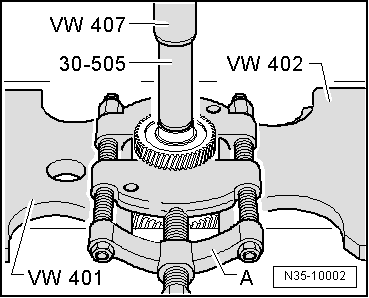

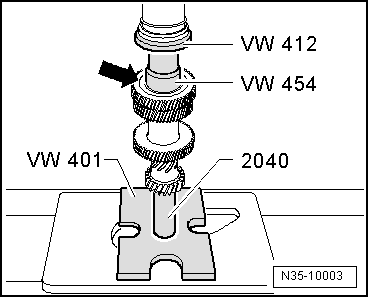

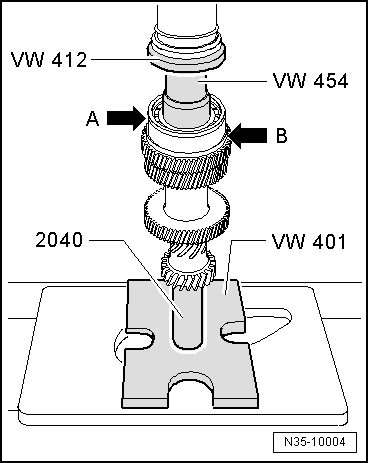

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

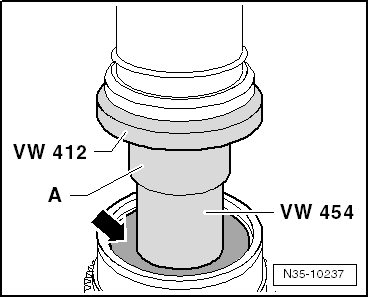

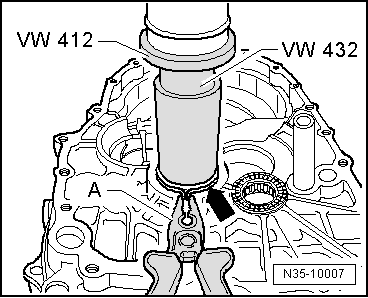

| t | Press tool -VW 412- |

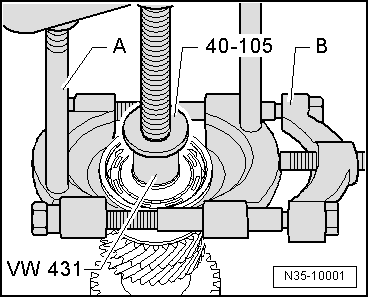

| t | Press tool -VW 431- |

| t | Press tool -VW 432- |

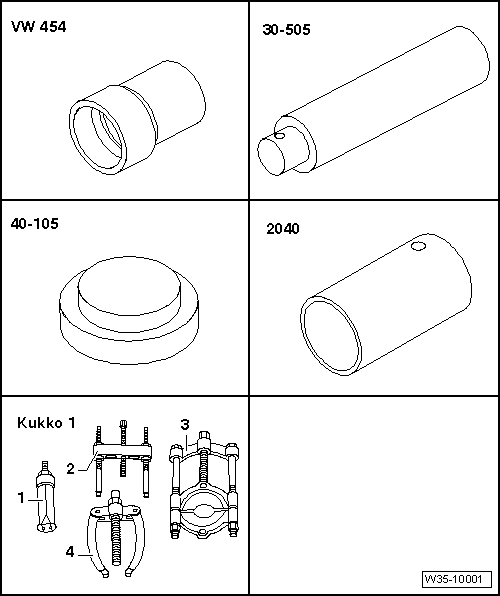

| t | Press tool -VW 454- |

| t | Mandrel -30 - 505- |

| t | Thrust plate -40 - 105- |

| t | Tube -2040- |

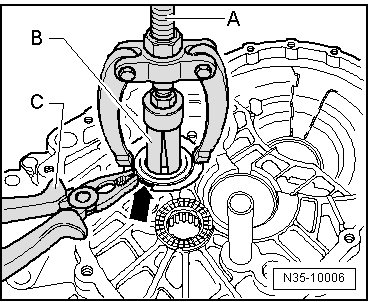

| t | -1- Kukko internal puller 21/5 |

| t | -2- Puller 18/1 |

| t | -3- Splitter 17/1 and 17/2 |

| t | -4- Kukko 22/2 counter-support |

|

|

|

|

|

|

|

|

|

|

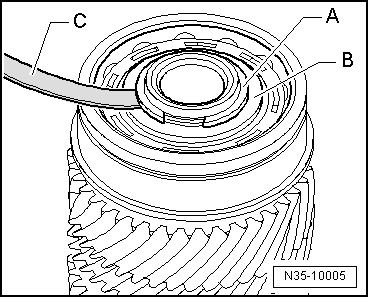

| Measured value (mm) | Circlip thickness (mm) | Axial clearance (mm) |

| 0.01 … 0.05 | 1.86 | 0.01 … 0.05 |

| 0.05 … 0.07 | 1.89 | 0.01 … 0.05 |

| 0.07 … 0.10 | 1.92 | 0.01 … 0.05 |

| 0.10 … 0.13 | 1.95 | 0.01 … 0.05 |

| 0.13 … 0.16 | 1.98 | 0.01 … 0.05 |

|

|

|

|