A3 Mk2

| Removing and installing flexible coupling (rear) |

| Special tools and workshop equipment required |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

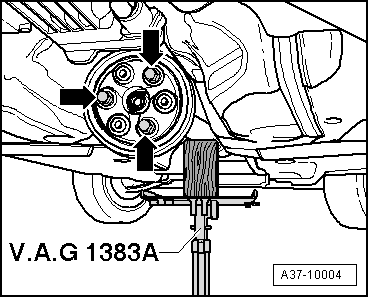

| t | Engine and gearbox jack -V.A.G 1383 A- with universal gearbox support -V.A.G 1359/2- |

Note

Note

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|