A3 Mk2

|

|

|

|

|

|

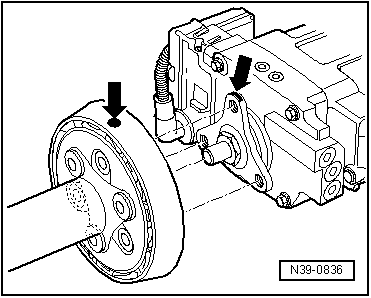

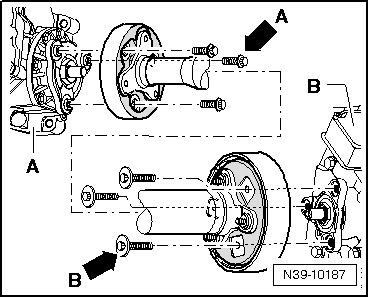

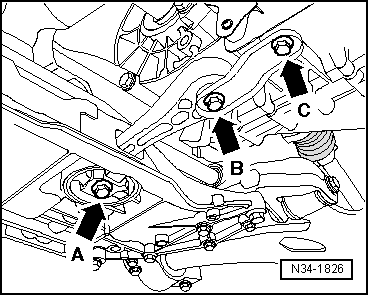

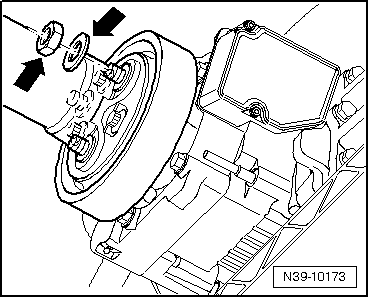

| Flange bolt with | Fitting location |

| small collar -arrow A- | Propshaft to front final drive -A-. Tightening torque → Item |

| large collar -arrow B- | Propshaft to rear final drive -B-. Tightening torque → Item |

|

|

|

|

|

|

|

|

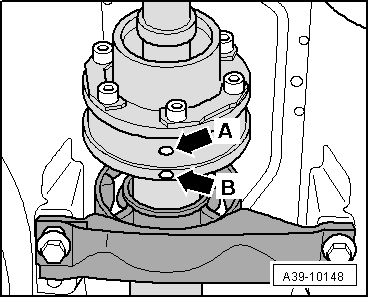

| Component | Nm | |

| Pendulum support to: | Gearbox -arrows B and C- | 40 Nm + 90° 1) |

| Subframe -arrow A- | 100 Nm + 90° 1) | |

| 1) Renew bolts | ||

Note

Note |

|

|

|