| –

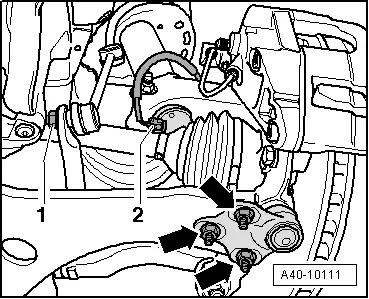

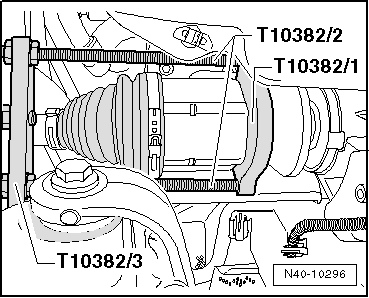

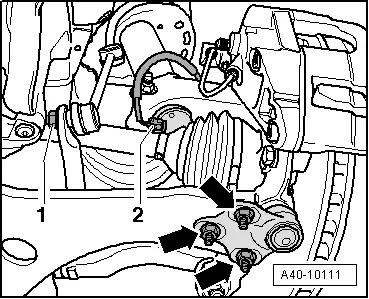

| Pull out drive shaft by striking multi-purpose tool -VW 771- as required. |

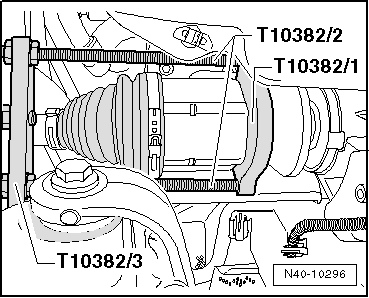

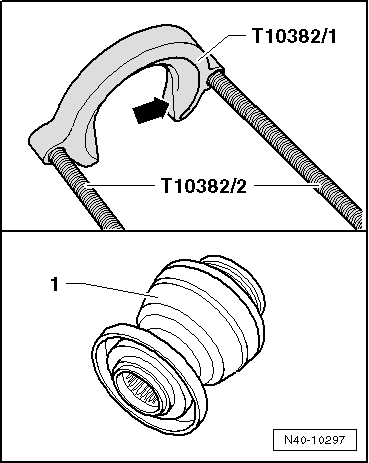

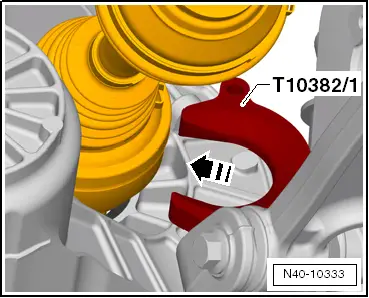

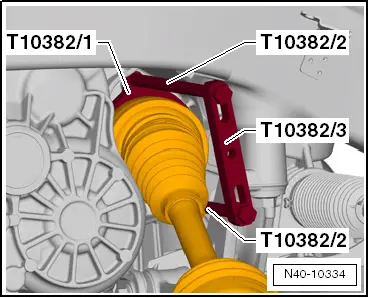

Note | When removing drive shaft on right side, ensure sufficient clearance from heat shield; re-position drive shaft puller -T10382- as necessary. |

| –

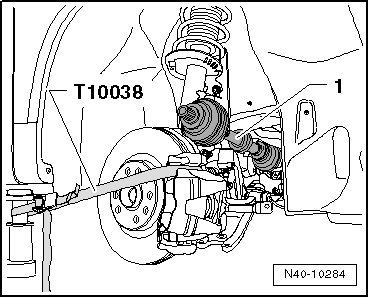

| Take drive shaft out of vehicle. |

| Installation is performed in reverse sequence; note the following: |

| Four-wheel drive vehicles |

| –

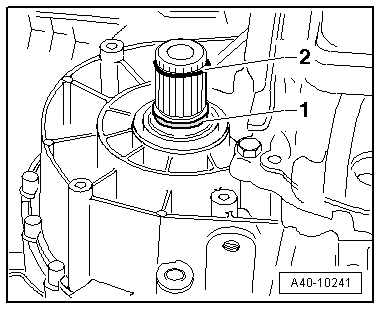

| Strike end of stub shaft (right-side) using a plastic hammer. |

Caution | l

| This ensures that the circlip on the stub shaft engages correctly in the differential pinion. |

| l

| It will also help to prevent leakage. |

|

| –

| Before fitting the outer joint in the wheel hub, apply a thin coat of assembly paste to the splines on the outer joint → Electronic parts catalogue. |

| Remove any paint residue and/or corrosion on thread and splines of outer joint. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution