A4 Cabriolet Mk2

| Removing engine - vehicles with automatic gearbox |

| Special tools and workshop equipment required |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Spark plug connector pliers -V.A.G 1922- |

| t | Stepladder -VAS 5085- |

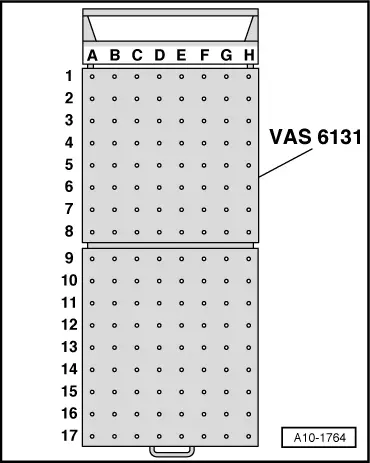

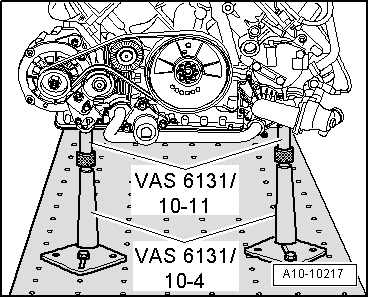

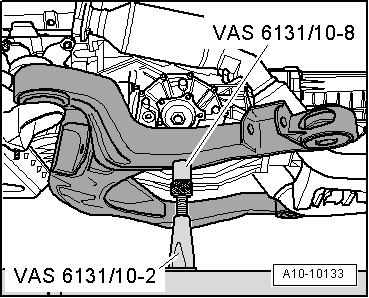

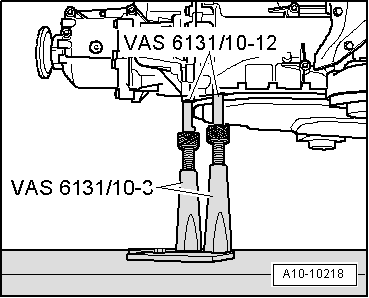

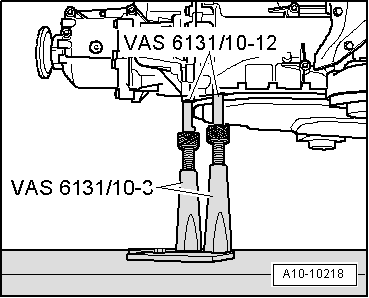

| t | Scissor-type assembly platform -VAS 6131 A- with support set for Audi -VAS 6131/10- |

| t | Drip tray for workshop hoist -VAS 6208- |

Note

Note

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

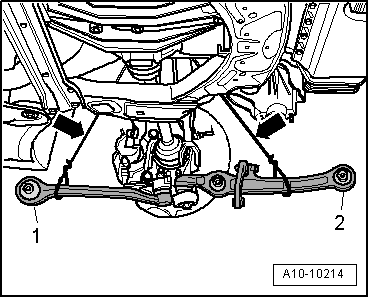

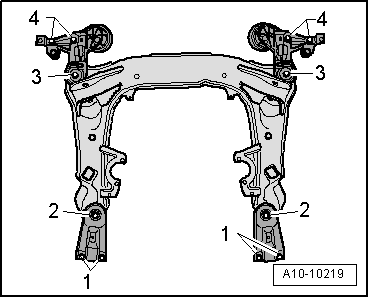

| Platform coordinates | Parts of support set for Audi -VAS 6131/10- | |||

| B4 | /10-1 | /10-4 | /10-5 | /10-11 |

| G3 | /10-1 | /10-4 | /10-5 | /10-11 |

| B10 | /10-1 | /10-2 | /10-5 | /10-8 |

| G10 | /10-1 | /10-2 | /10-5 | /10-8 |

| C15 | /10-1 | /10-3 | /10-5 | /10-12 |

| F15 | /10-1 | /10-3 | /10-5 | /10-12 |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution WARNING

WARNING