A4 Mk1

|

Servicing rear axle (four-wheel drive vehicles)

Removing and installing rear axle

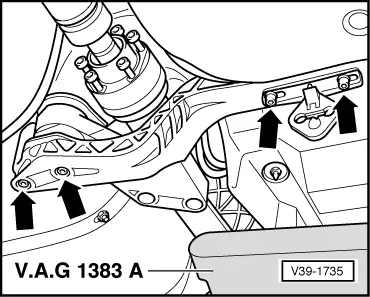

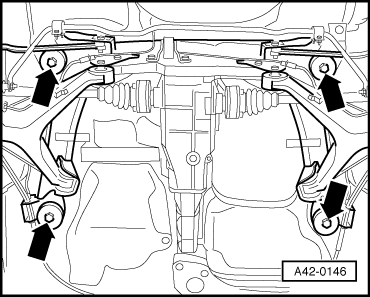

Special tools and workshop equipment required

Removing |

|

|

=> General Body Repairs; Repair Group 70; Shelves/Trim, Removing and installing rear centre console

=> Engine, Mechanics; Repair Group 26; Removing and installing exhaust system components Note: To avoid damage, decoupling element in front exhaust pipe is never to be kinked by more than 10 °.

|

|

|

|

|

|

=> Brake System; Repair Group 46; Removing and installing handbrake cables Note: If same rear axle is to be re-installed, only disengage handbrake cables at handbrake lever, on underside of vehicle and at fuel tank. In this case, handbrake cables at rear axle and brake calipers are to be left engaged. |

|

|

|

|

|

|

|

|

Notes:

|

|

|

Notes:

|

|

|

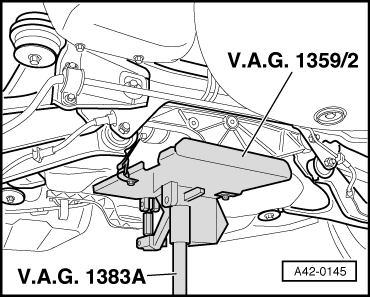

Note: Take care not to damage fuel tank. |

|

|

|

|

|

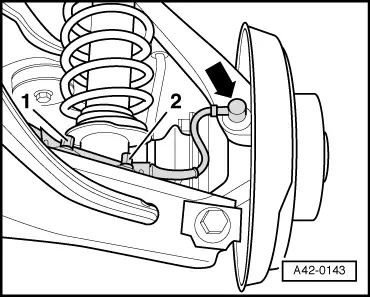

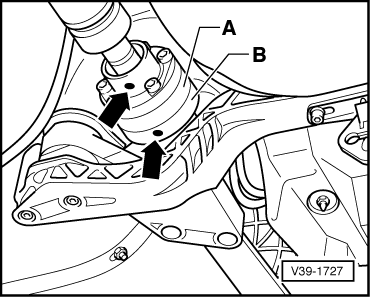

Note: Take care not to damage edge of wheel housing. Installing Install in reverse order, paying attention to the following: Remove any paint remnants, adhesive remnants and or/corrosion in thread/splines. Notes: |

|

||||||||||||||||

=> Brake System; Repair Group 46; Bleeding brake system

=> Brake System; Repair Group 46; Removing and installing handbrake lever

=> Engine, Mechanics; Repair Group 26; Removing and installing exhaust system components

Tightening torques

1) Replace bolt 2) 90°corresponds to quarter turn 3) Replace nut |