A4 Mk2

| Dismantling and assembling pinion shaft from 05.03 |

| Special tools and workshop equipment required |

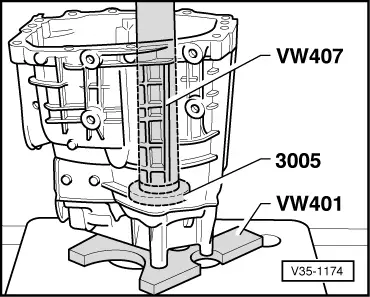

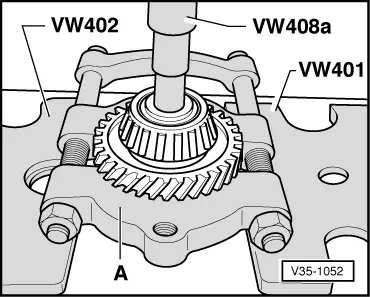

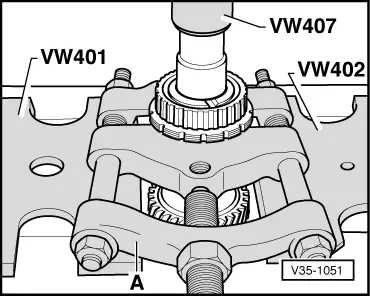

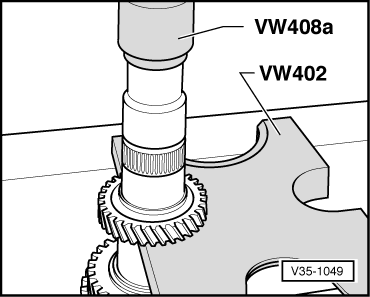

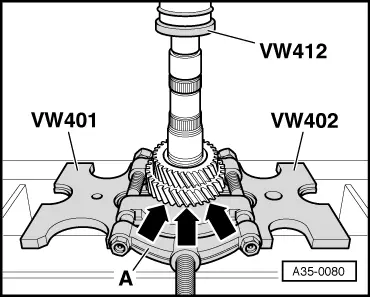

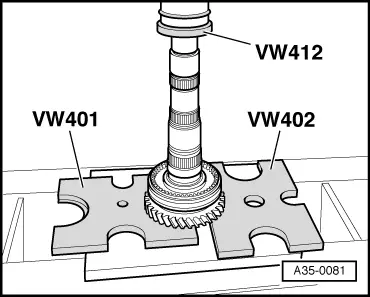

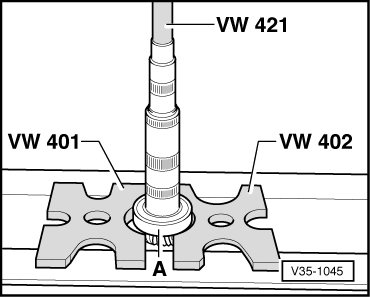

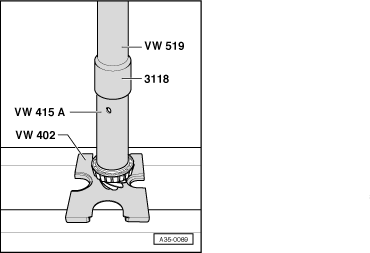

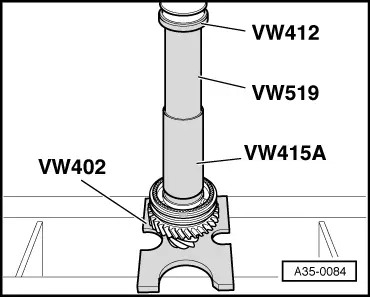

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 408 A- |

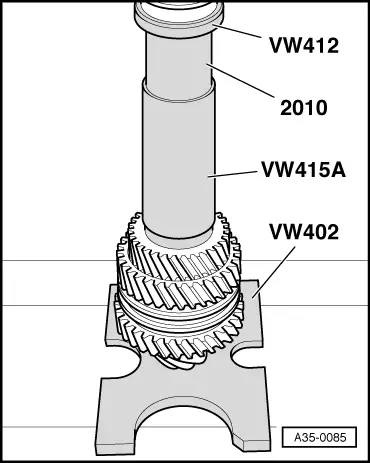

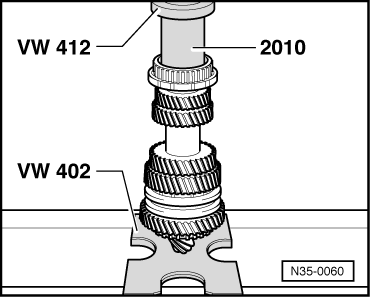

| t | Press tool -VW 412- |

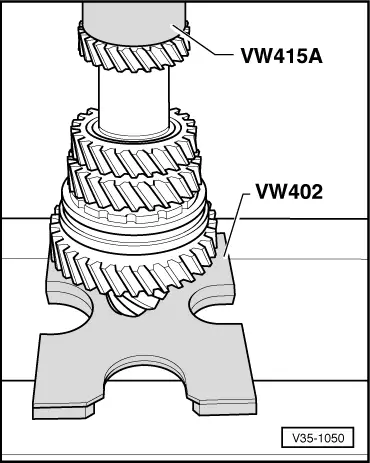

| t | Tube -VW 415 A- |

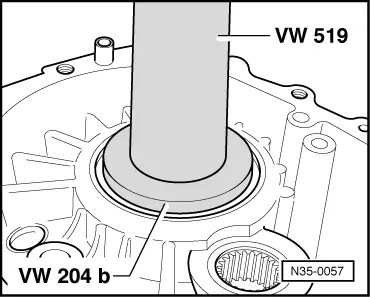

| t | Crankshaft seal installing tool -VW 204 B- |

| t | Tube -VW 421- |

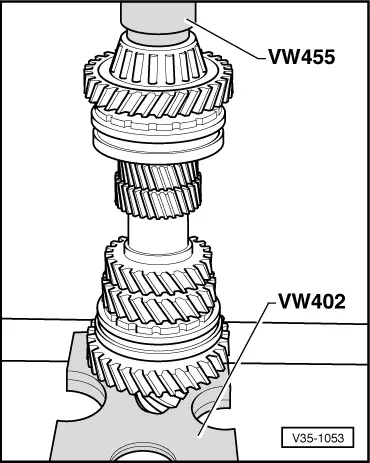

| t | Installing sleeve -VW 455- |

| t | Tube -VW 519- |

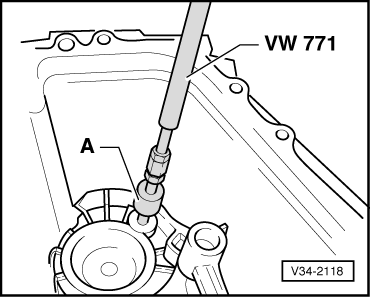

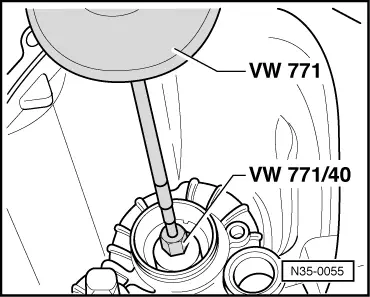

| t | Multi-purpose tool -VW 771- |

| t | Tube -2010- |

| t | Thrust plate -3005- |

| t | Press tool -3118- |

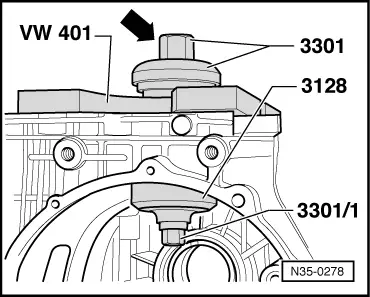

| t | Fitting tool -3128- |

| t | Assembly tool -3301- |

| t | -1-Internal puller -Kukko 21/1- |

| t | -1-Internal puller -Kukko 21/4- |

| t | -3-Splitter -Kukko 17/2- |

Note

Note| t | From 05.03 onwards, a new synchromesh mechanism was introduced with triple synchromesh on 1st gear and double synchromesh on 2nd gear as well as synchro-rings with larger friction cone and smaller dog teeth on 5th and reverse gear. The selector gears, locking collars and synchronising hubs are modified accordingly; these parts cannot be installed together with synchromesh components of the previous version. |

| t | Refer to technical data → Chapter when installing new gear wheels or the final drive gear set. |

| t | Adjustment work is required when renewing the parts marked with 1) → Chapter „Table of adjustments“. |

| 1 - | Gearbox housing 1) |

| q | Housing manufactured from aluminium or magnesium → Item |

| 2 - | Shim “S3” |

| q | Table of adjustments → Chapter |

| 3 - | Outer race for large tapered roller bearing 1) |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

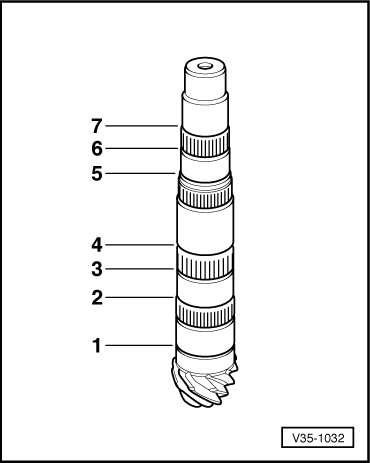

| 4 - | Pinion shaft 1) |

| q | Is mated with crown wheel, always renew together as a set |

| q | Adjusting pinion shaft and crown wheel → Chapter |

| 5 - | Inner race for large tapered roller bearing 1) |

| q | Will be damaged during removal |

| q | Renew |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

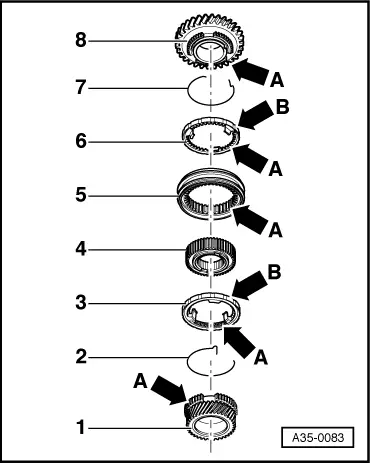

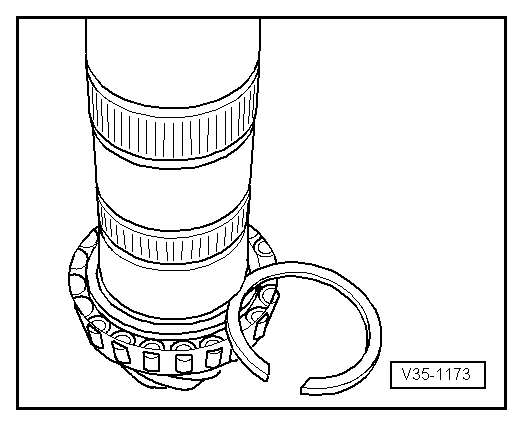

| 6 - | Circlip |

| q | Mark |

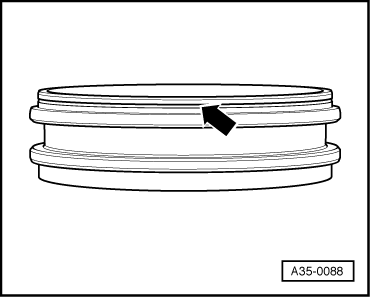

| q | Installation position → Fig. |

| q | Re-determine thickness if tapered roller bearing is renewed → Fig. |

| 7 - | Needle bearing for 1st gear |

| 8 - | 1st speed selector gear |

| 9 - | Inner ring for 1st gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 10 - | Intermediate ring for 1st gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 11 - | Synchro-ring for 1st gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

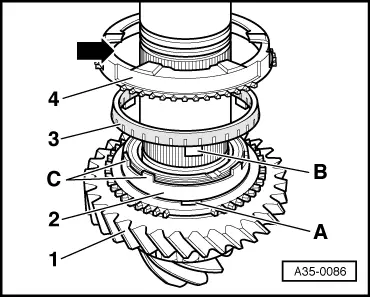

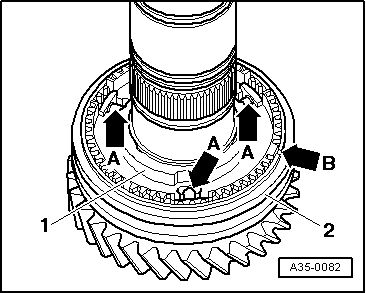

| 12 - | Locking collar for 1st and 2nd gear |

| q | Mark installation position |

| q | Assembling locking collar/synchronising hub → Fig. |

| 13 - | Locking piece |

| q | Installing locking pieces (3x) → Fig. |

| 14 - | Synchronising hub for 1st and 2nd gear |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| q | Assembling locking collar/synchronising hub → Fig. |

| 15 - | Circlip |

| q | Mark |

| q | Installation position → Fig. |

| q | Redetermine thickness if synchronising hub is replaced → Fig. |

| 16 - | Needle bearing for 2nd gear |

| 17 - | Synchro-ring for 2nd gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 18 - | Intermediate ring for 2nd gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| 19 - | Inner ring for 2nd gear |

| q | Installation position → Fig. |

| q | Checking for wear → Fig. |

| q | Renew if scored or if there are visible traces of wear |

| 20 - | 2nd speed selector gear |

| 21 - | Circlip |

| q | Mark |

| q | Installation position → Fig. |

| 22 - | 3rd gear wheel |

| q | Pressing off → Fig. |

| q | Groove faces 4th gear |

| q | Pressing on → Fig. |

| 23 - | Circlip |

| q | Mark |

| q | Installation position → Fig. |

| q | If the 3rd gear wheel is renewed redetermine thickness → Fig. |

| 24 - | 4th gear wheel |

| q | Pressing off → Fig. |

| q | Shoulder faces towards 3rd gear |

| q | Pressing on → Fig. |

| 25 - | Circlip |

| q | Mark |

| q | Installation position → Fig. |

| q | If the 4th gear wheel is renewed redetermine thickness → Fig. |

| 26 - | Needle bearing |

| 27 - | 5th speed selector gear |

| q | Distinctive feature of modification → Fig. |

| 28 - | Spring |

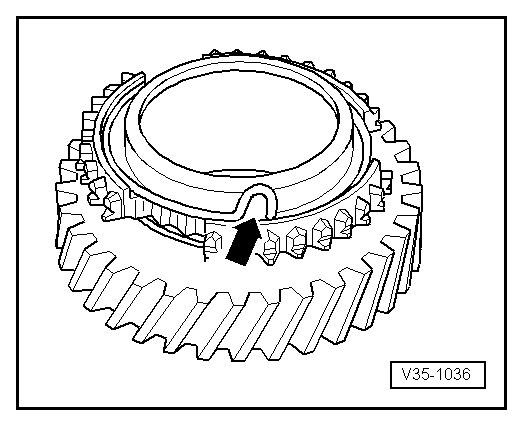

| q | Distinctive feature of modification → Fig. |

| q | Insert in 5th speed selector gear → Fig. |

| q | Allocation to selector gear → Electronic parts catalogue |

| 29 - | Synchro-ring for 5th gear |

| q | Distinctive feature of modification → Fig. |

| q | Checking for wear → Fig. |

| 30 - | Circlip |

| q | Mark |

| q | Installation position → Fig. |

| 31 - | 5th gear and reverse gear synchronising hub |

| q | Distinctive feature of modification → Fig. |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 32 - | Circlip |

| q | Mark |

| q | Installation position → Fig. |

| q | Redetermine thickness if synchronising hub is replaced → Fig. |

| 33 - | Needle bearing |

| q | For reverse gear |

| 34 - | Locking collar for 5th and reverse gear |

| q | Distinctive feature of modification → Fig. |

| q | Installation position: groove faces towards 5th gear → Fig. |

| 35 - | Synchro-ring for reverse gear |

| q | Distinctive feature of modification → Fig. |

| q | Checking for wear → Fig. |

| 36 - | Spring |

| q | Distinctive feature of modification → Fig. |

| q | Insert in reverse selector gear → Fig. |

| q | Allocation to selector gear → Electronic parts catalogue |

| 37 - | Reverse selector gear |

| q | Distinctive feature of modification → Fig. |

| 38 - | Inner race for small tapered roller bearing 1) |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| 39 - | Bush |

| q | Secures outer race for small tapered roller bearing |

| q | Pulling out → Fig. |

| q | Need not be refitted after the small taper roller bearing has been renewed |

| 40 - | Outer race for small tapered roller bearing 1) |

| q | Pulling out → Fig. |

| q | Pressing in → Fig. |

| 41 - | Shim “S4” |

| q | Table of adjustments → Chapter |

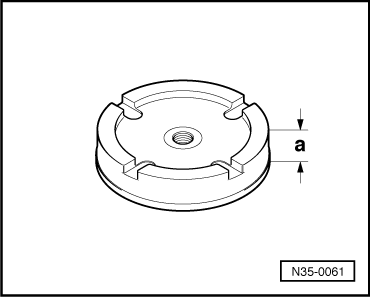

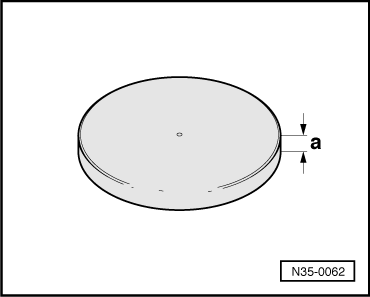

| 42 - | Pressure plate |

| q | Different thicknesses for aluminium and magnesium gearboxes → Fig. |

| 43 - | Rubber disc |

| q | Compensates length variations |

| q | To remove, screw self-tapping screw into centre of disc and use screw to pull out disc |

| q | Different thicknesses for aluminium and magnesium gearboxes → Fig. |

| q | Select correct version according to gearbox code letters → Electronic parts catalogue → Chapter |

| 44 - | Gearbox cover |

| q | Aluminium version: must only be fitted to an aluminium gearbox housing |

| q | Magnesium version: must only be fitted to a magnesium gearbox housing |

| q | Note identification markings → Fig. |

| q | Coat sealing surfaces lightly with sealing paste -AMV 188 001 02- |

| q | Can be renewed with gearbox in vehicle → Chapter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Circlip thickness (mm) | ||

| 2.00 | 2.06 | 2.12 |

| 2.03 | 2.09 | 2.15 |

|

| Circlip thickness (mm) | ||

| 1.90 | 1.96 | 2.02 |

| 1.93 | 1.99 | |

|

| Circlip thickness (mm) | ||

| 2.50 |

|

| Circlip thickness (mm) | ||

| 1.90 | 1.98 | 2.06 |

| 1.94 | 2.02 | |

|

| Circlip thickness (mm) | ||

| 1.86 | 1.94 | |

| 1.90 | 1.98 | |

|

| Circlip thickness (mm) | ||

| 2.00 |

|

| Circlip thickness (mm) | ||

| 1.90 | 1.96 | 2.02 |

| 1.93 | 1.99 | 2.05 |

Note

Note

|

|

|

|

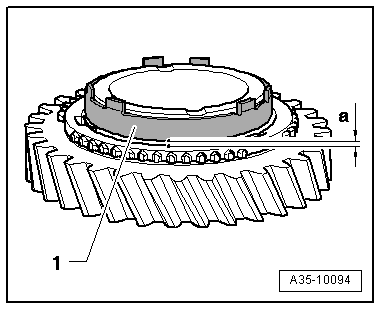

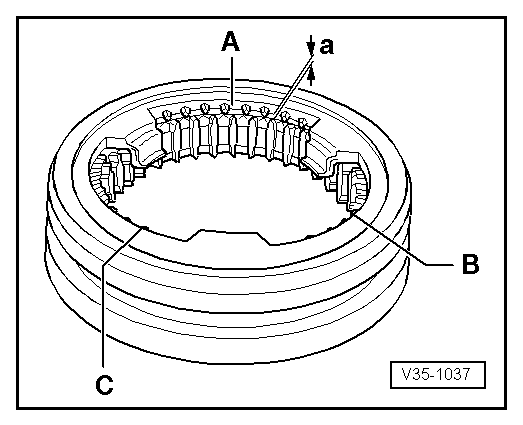

| Gap “a” | As-new installation value | Wear limit |

| Inner ring for 1st gear | 1.2 ... 2.0 mm | 0.6 mm |

|

|

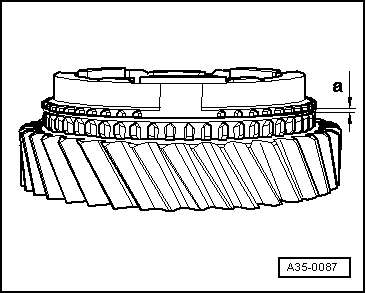

| Gap “a” | As-new installation value | Wear limit |

| 1st and 2nd gear | 1.4 ... 2.0 mm | 0.8 mm |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

| Gearbox housing | Distance -a- |

| Aluminium | 14.8 or 15.3 mm |

| Magnesium → Chapter | 10.7 mm |

|

|

| Gearbox housing | Distance -a- |

| Aluminium | 7.0 mm |

| Magnesium | 11.0 mm |