| –

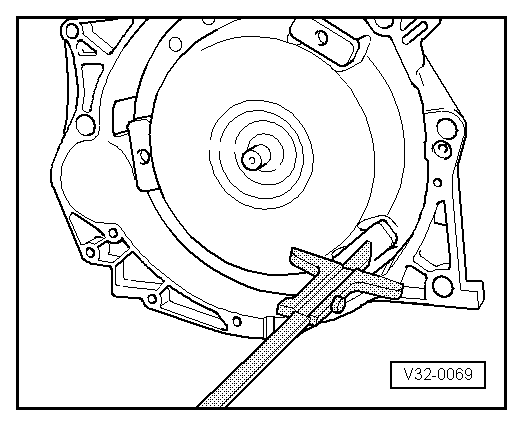

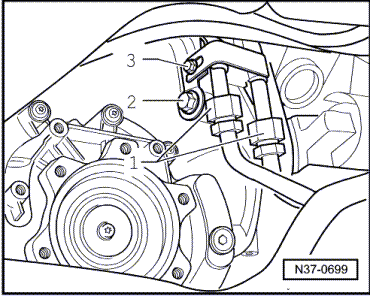

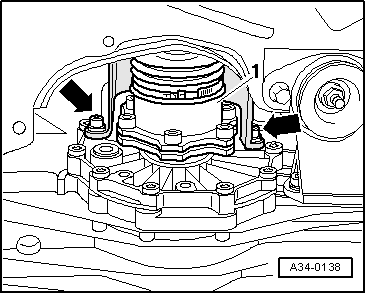

| Before installing the gearbox ensure that the torque converter has been correctly fitted in the gearbox → Chapter. |

| l

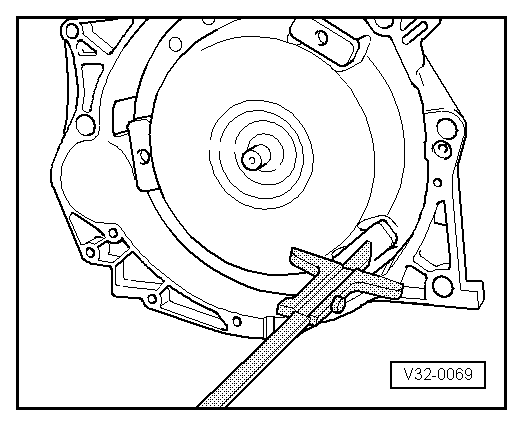

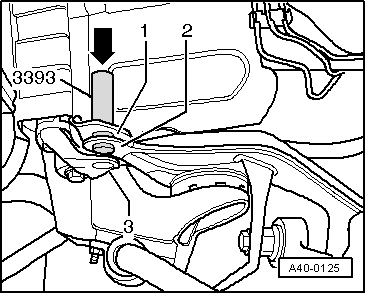

| If the torque converter is correctly installed, the depth between the contact surfaces at the tapped holes on the torque converter and the contact surface of the torque converter bellhousing will be approx. 23 mm. |

| l

| If the torque converter has not been fully inserted, the distance will be only approx. 11 mm. |

Caution | If the torque converter is not fitted correctly, the drive lugs on the torque converter or the ATF pump will be irreparably damaged when the gearbox is joined to the engine. |

|

| –

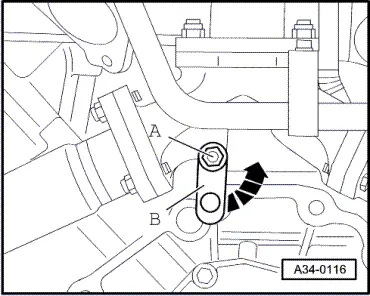

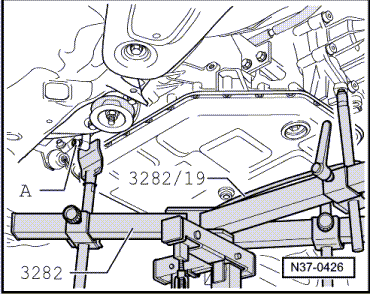

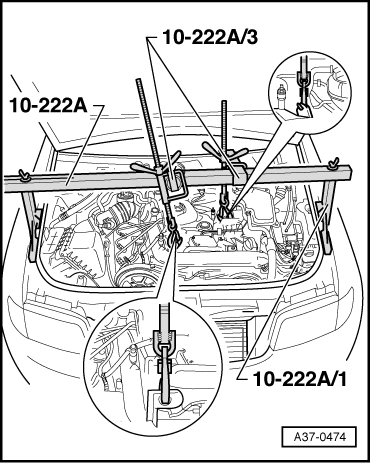

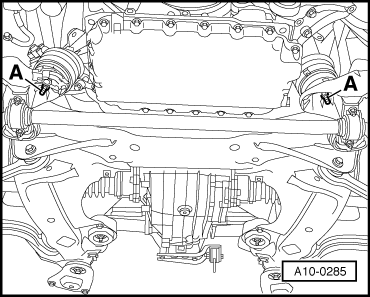

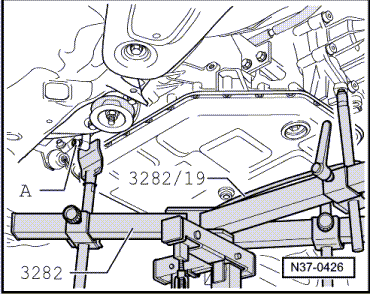

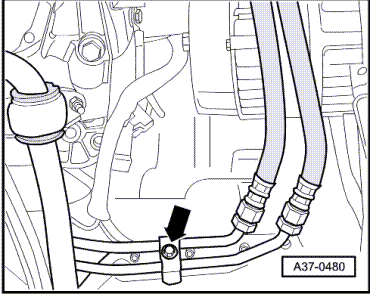

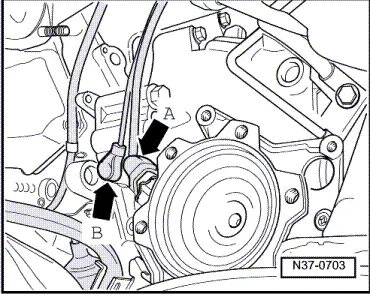

| Guide in gearbox between lowered subframe and underbody. |

| –

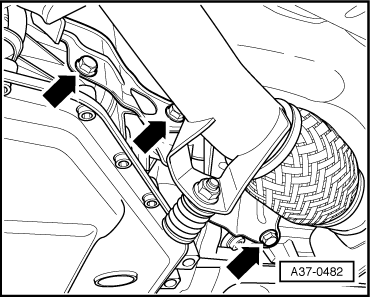

| Align gearbox with engine. |

| –

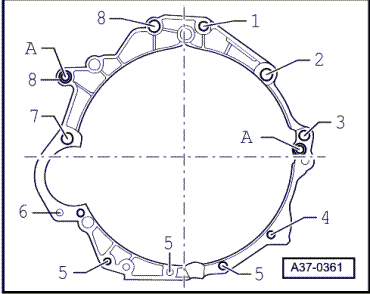

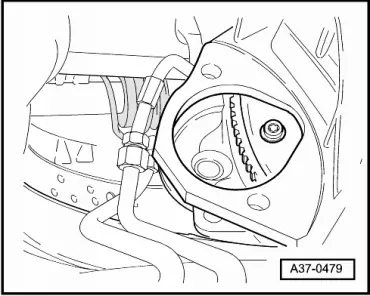

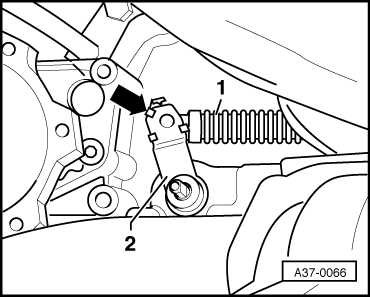

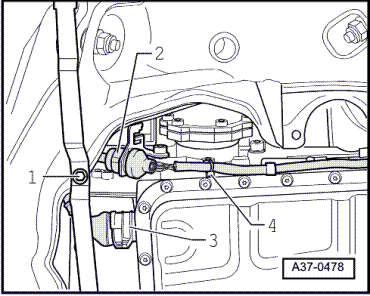

| Before joining engine and gearbox, turn torque converter and drive plate (on engine) until one hole and one tapped hole are in line with the opening for the removed starter. |

Note | Make sure that no wiring or pipes are trapped when bringing engine and gearbox together. |

| –

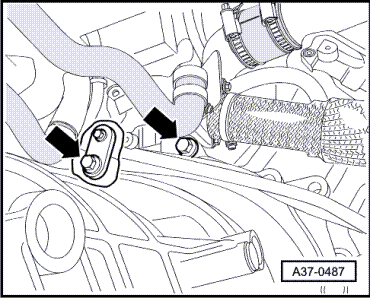

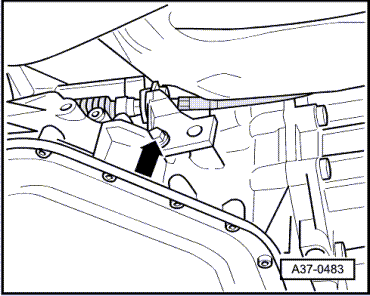

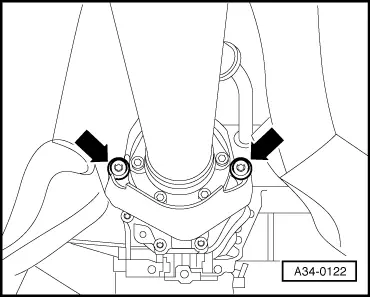

| Install one engine/gearbox securing bolt on each side and tighten hand-tight. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING