A4 Mk2

| Removing |

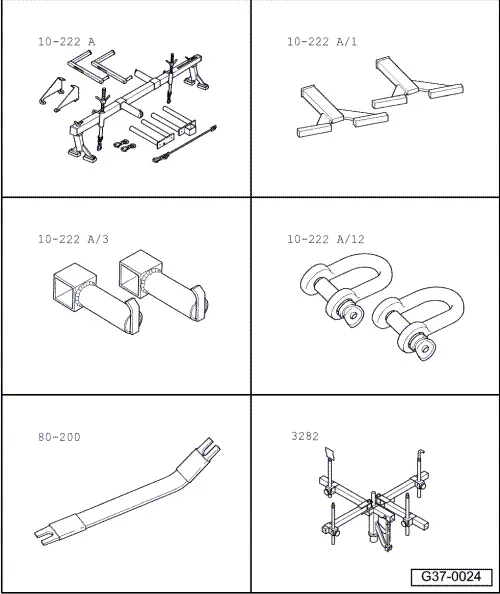

| Special tools and workshop equipment required |

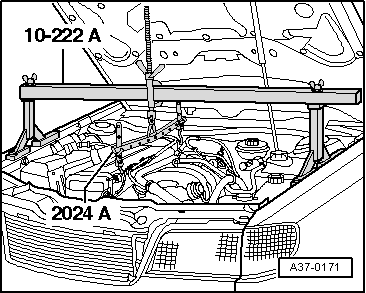

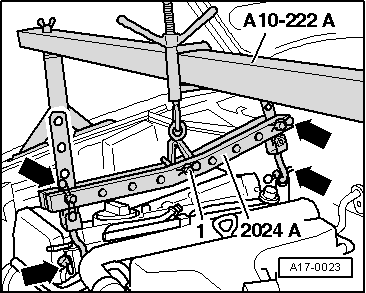

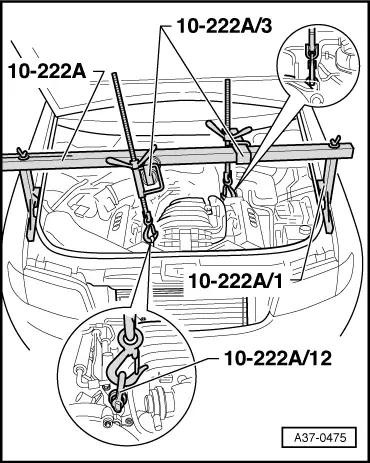

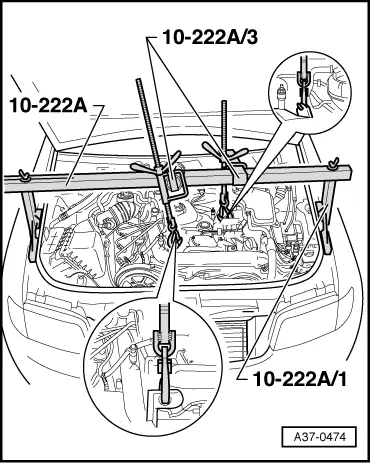

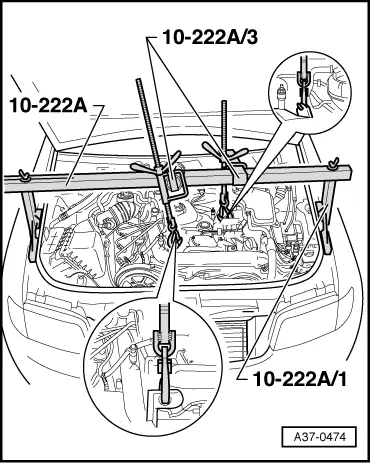

| t | Support bracket -10 - 222 A- |

| t | Rack -10 - 222 A/ 1- |

| t | Adapter -10 - 222 A /3- |

| t | Shackle -10 - 222 A /12- |

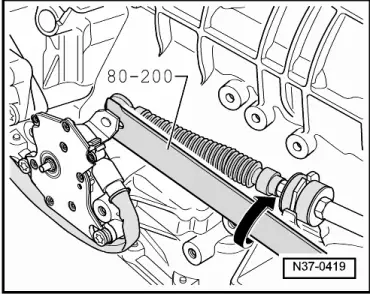

| t | Removal lever -80 - 200- |

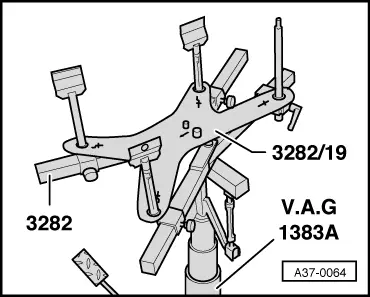

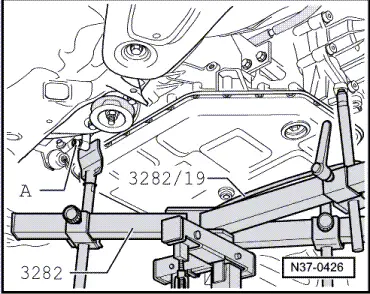

| t | Gearbox support -3282- |

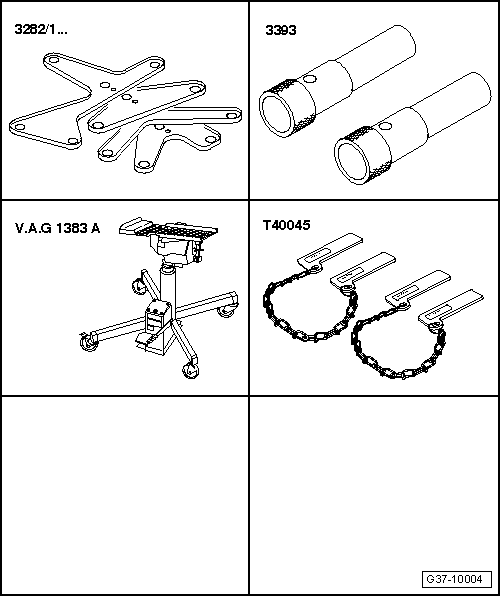

| t | Adjustment plate -3282/19- |

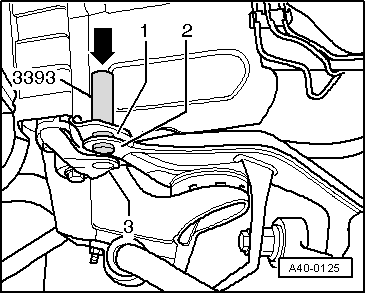

| t | Locating pins -3393- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

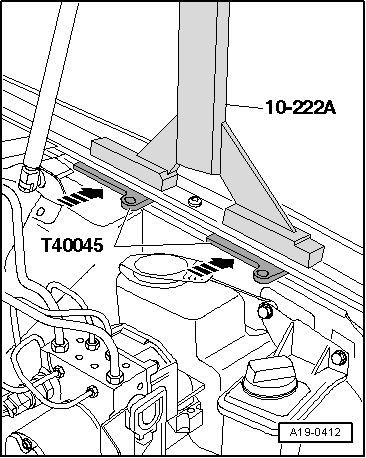

| t | Wing compensation plate -T40045- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Caution

Caution